Grinding Sticks For Diamond Grinding Wheel

0.3 USD ($)/Piece

Product Details:

- Chemical Composition Al2O3

- Bonding Resin Bonded

- Hardness Medium

- Shape Rectangular

- Toughness High

- Grain Type Fine

- Material Aluminium Oxide

- Click to View more

X

Grinding Sticks For Diamond Grinding Wheel Price And Quantity

- 3000 Millimeter

- 0.3 USD ($)/Piece

- Diamond Grinding Wheels

- Up to 550°C

- Dressing Diamond Grinding Wheels

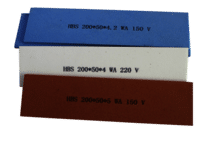

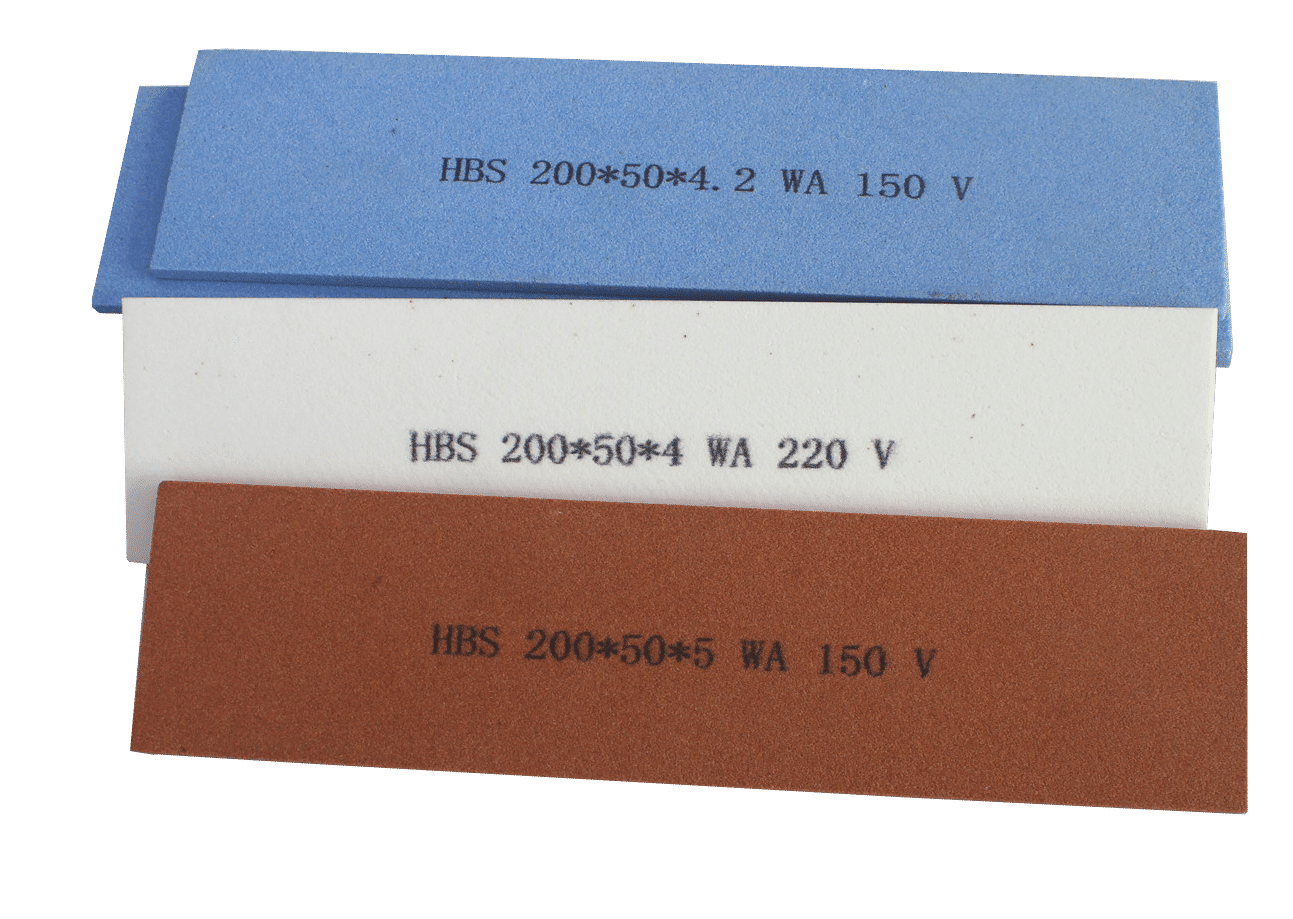

- White / Off-White

- Boxed

- Smooth

- Approx. 50 g per stick

- 150 mm

- Below 60°C

Grinding Sticks For Diamond Grinding Wheel Product Specifications

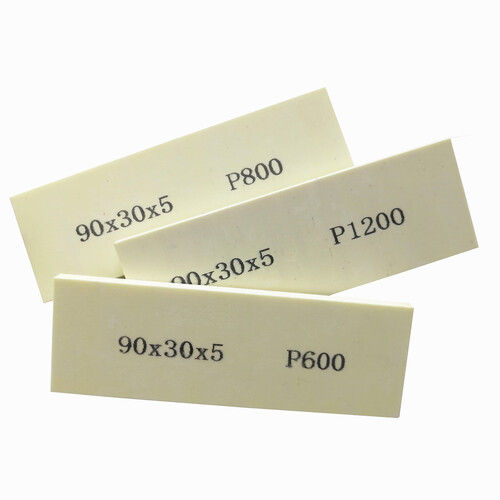

- 100 mm x 10 mm

- 70-240 grit

- Aluminium Oxide

- Medium

- Grinding Stick

- Resin Bonded

- 150 mm x 10 mm

- Fine

- High

- Rectangular

- Al2O3

- Diamond Grinding Wheels

- Up to 550°C

- Dressing Diamond Grinding Wheels

- White / Off-White

- Boxed

- Smooth

- Approx. 50 g per stick

- 150 mm

- Below 60°C

Product Description

Grinding Sticks for Diamond Grinding Wheel

Product Description:

Grinding stick for diamond grinding wheel is applied to keep your tool sharp and safe in the operation. For long time using, the edges of diamond grinding wheel will be worn, causing tearing rather than grinding, exposed your workpiece and work tool damaging risks. Therefore, Hongbaoshi dressing stick would be ideal item for you turning to to resharpen your diamond grinding tools.

|

Grinding Sticks for Diamond Grinding Wheel in Glass Industry |

||||

|

Length |

Width |

Thickness |

Abrasive |

Grit |

|

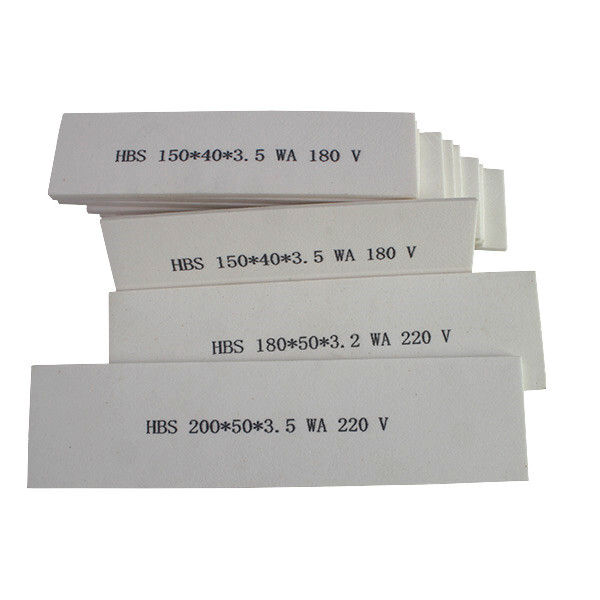

200 |

50 |

2.0,2.5,3.0,3.5,4.0, 4.2,4.5,4.9,5.0 |

WA |

150#, 180#, 220#, 240# |

|

200 |

50 |

5.0,5.2,6.0,6.5,8.0,9.0 |

WA |

150#, 180#, 220#, 240# |

Efficient Dressing for Diamond Grinding Wheels

Aluminium oxide grinding sticks are expertly engineered to restore and maintain diamond grinding wheels. Their fine, medium, and tough composition enables effective removal of debris without compromising the wheel's integrity. This leads to improved grinding accuracy and a smoother finish on workpieces, making them indispensable in manufacturing and metalworking settings.

Durable and User-Friendly Shape and Size

Each grinding stick is rectangular, measuring 150 mm x 10 mm, and presents a smooth, easy-to-handle surface. Whether used as strips or rolls, they are lightweight and manageable, perfectly sized for various dressing tasks. Their versatile grain sizes allow precise application, adaptable to different levels of wheel wear.

FAQ's of Grinding Sticks For Diamond Grinding Wheel:

Q: How are these grinding sticks used for dressing diamond grinding wheels?

A: To use the grinding stick, gently press it against the rotating diamond grinding wheel at the recommended operating temperature. Move the stick across the wheel's surface to remove embedded debris and expose fresh abrasive grains, which helps maintain the wheel's cutting efficiency.Q: What makes aluminium oxide grinding sticks suitable for diamond grinding wheels?

A: Aluminium oxide (Al2O3) provides high toughness and medium hardness, making these sticks effective for dressing diamond grinding wheels without causing excessive wear. Their fine grain and resilient structure optimize both the cleaning and restoration process.Q: When should I apply a grinding stick to my diamond grinding wheel?

A: Grinding sticks should be used periodically during wheel maintenance, particularly when the wheel shows signs of loading, reduced performance, or uneven grinding results. Regular use prolongs the wheel's lifespan and enhances its operational efficiency.Q: Where can these grinding sticks be stored safely?

A: They should be stored in a dry environment below 60C, preferably in their original boxed packaging, to maintain their structural integrity and prevent deterioration from excess humidity or temperature.Q: What is the typical process for dressing a wheel with a grinding stick?

A: Begin by securely mounting the stick close to the wheel. With the wheel spinning at operating speed (up to 550C tolerated), lightly touch the stick to the wheel's surface and traverse it evenly across the area requiring dressing. Continue until the wheel regains its sharpness and a smooth profile.Q: What benefits do these grinding sticks offer for industrial users?

A: They extend the functional life of diamond grinding wheels by efficiently removing waste material, thus preserving cutting performance. Their fine grain sizes ensure precise dressing, and the high durability of aluminium oxide makes them a cost-efficient and reliable choice for frequent use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese