Glass Field Grinding Stones Dressing sticks

0.3 USD ($)/Piece

Product Details:

- Bonding Vitrified bonding

- Toughness High durability and wear resistance

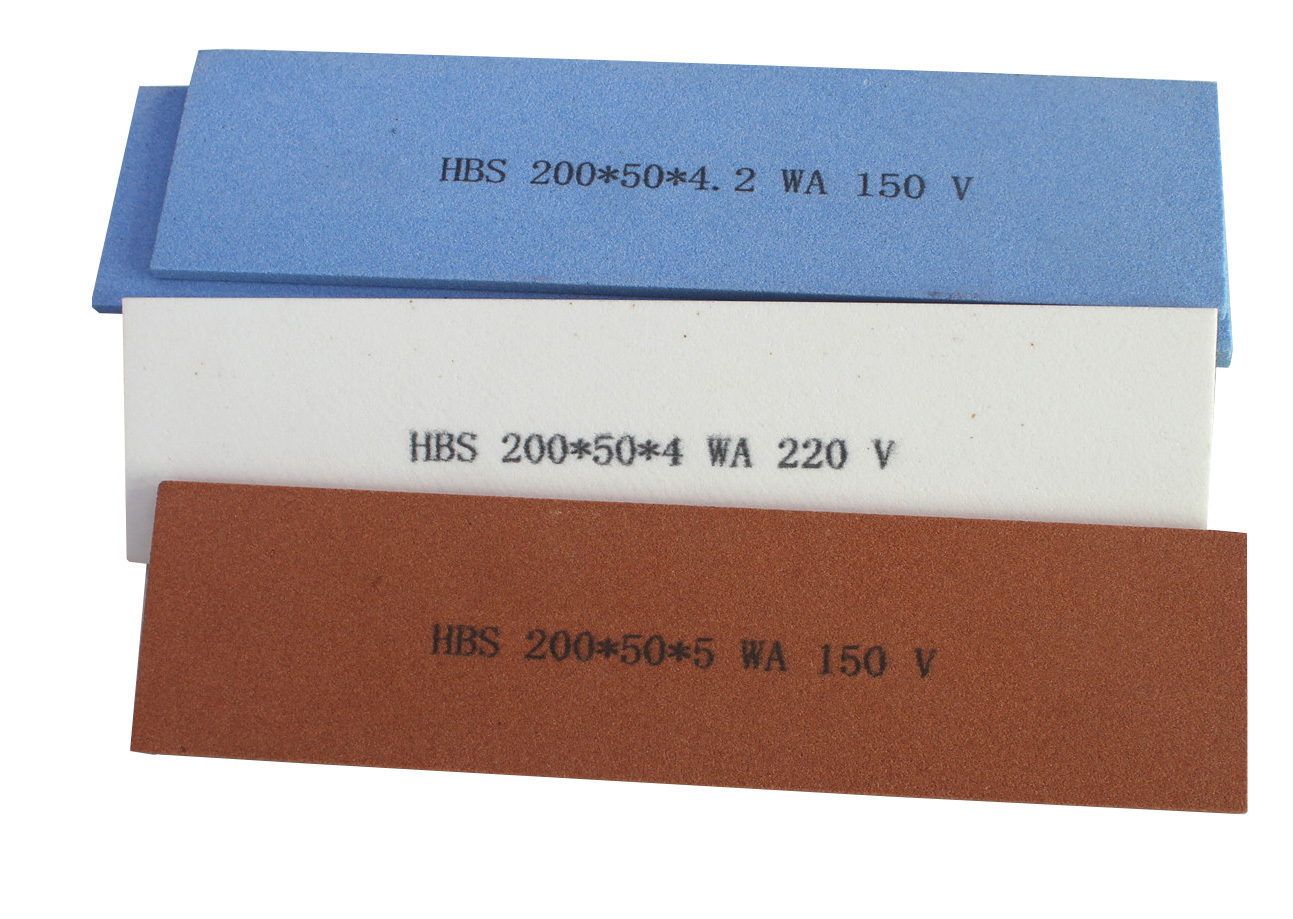

- Shape Rectangular, Square, and Strip Shapes

- Backing None (solid stick design)

- Chemical Composition Al2O3 (Aluminum Oxide) or SiC (Silicon Carbide)

- Hardness Medium to hard

- Grain Type Coarse, Medium, Fine options

- Click to View more

X

Glass Field Grinding Stones Dressing sticks Price And Quantity

- 0.3 USD ($)/Piece

- 3000 Piece

Glass Field Grinding Stones Dressing sticks Product Specifications

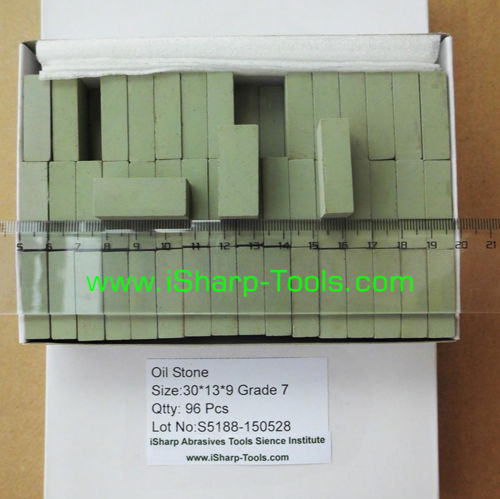

- Standard widths from 10mm to 25mm, lengths 100mm to 250mm

- Al2O3 (Aluminum Oxide) or SiC (Silicon Carbide)

- High durability and wear resistance

- Aluminum Oxide, Silicon Carbide

- Medium to hard

- Rectangular, Square, and Strip Shapes

- Coarse, Medium, Fine options

- Dressing Stick (rectangular/strip form)

- Available from 80 Grit to 400 Grit

- Large and medium sizes available, typically from 150mm to 300mm

- None (solid stick design)

- Vitrified bonding

Product Description

Glass Field Grinding Stones Grinding Sticks

Glass field grinding stones grinding sticks introduction:

Glass field grinding stones grinding sticks can be used for diamond wheels and normal grinding wheels with different grits and hardness. With oil treated abrasives, the dressing stones can prevent wear loading and reach flawless finishing.

Glass field grinding stones grinding sticks application:

Application: Polishing and dressing of glass, diamond wheel, CBM wheel and general grinding wheels

Keyword: Dressing Oil Stones, Dressing stone, Abrasive sticks, Dressing sticks

Material: A/WA/C/GC

Feature: Smooth and flawless finishing

Service: Over years' consistent quality as free sample

Precision and Versatility in Glass Dressing

Engineered with vitrified bonding and a solid-stick design, these dressing sticks offer reliable performance for all types of field grinding stones used in glass processing. Their high-density composition ensures lasting durability and accurate results, even under frequent and intensive use. The availability of a range of grit sizes and customizable dimensions accommodates diverse operational needs.

Adaptable for Manual and Machine Applications

Whether you're manually dressing a grinding stone or using advanced machinery, these dressing sticks are designed for smooth and effective stone maintenance. Their non-porous structure and moisture resistance contribute to a longer service life and consistent results, even in demanding environments.

FAQ's of Glass Field Grinding Stones Dressing sticks:

Q: How are Glass Field Grinding Stones Dressing Sticks used in glass fabrication?

A: Dressing sticks are applied to grinding stones to clean, reshape, and extend their lifespan during glass fabrication. They remove debris and expose new abrasive layers on the stone, ensuring efficient cutting and polishing.Q: What variants of dressing sticks are available and how do I choose the right one?

A: They are offered in grey, green, and white variants, made from aluminum oxide or silicon carbide, and come in different grain sizes ranging from 80 to 400 grit. Selection depends on your required level of abrasion-coarse for heavy dressing, medium for routine maintenance, and fine for finishing touches.Q: Where can these dressing sticks be applied and in which settings?

A: These sticks are suitable for use in glass fabrication workshops, industrial processing lines, and facilities handling grinding stones. They can be used both manually or with machines wherever field grinding stones need cleaning or reshaping.Q: What are the benefits of using high-density, non-porous dressing sticks?

A: Their high density and non-porous structure provide exceptional wear resistance, longer service life, and resistance to moisture, making them ideal for demanding glass fabrication environments.Q: When should I use a dressing stick on my grinding stones?

A: Use a dressing stick whenever your grinding stone becomes glazed, clogged, or uneven. Regular dressing maintains the efficiency and surface quality of your stones, ensuring optimal glass fabrication results.Q: How can I order custom sizes and what packing options are available?

A: Custom sizes can be requested to suit specific needs, with available widths from 10mm to 25mm and lengths from 100mm to 250mm. Packing is typically in standard cartons or in bulk, depending on order quantity and client preference.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese