superfinishing honing stone

44.0 USD ($)/Piece

Product Details:

- Hardness J to M (customizable)

- Chemical Composition Al2O3 > 98%, minor SiO2 and Fe2O3

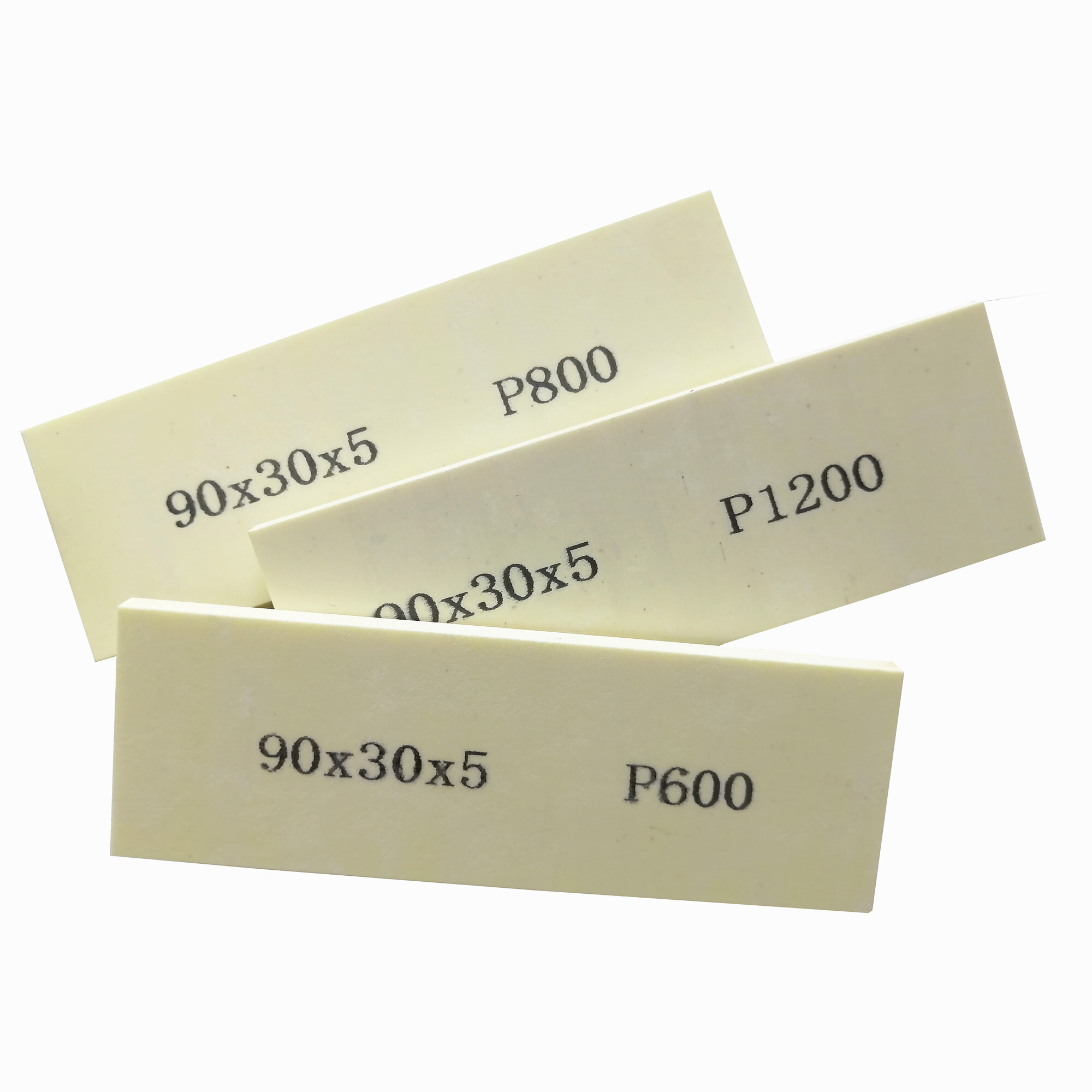

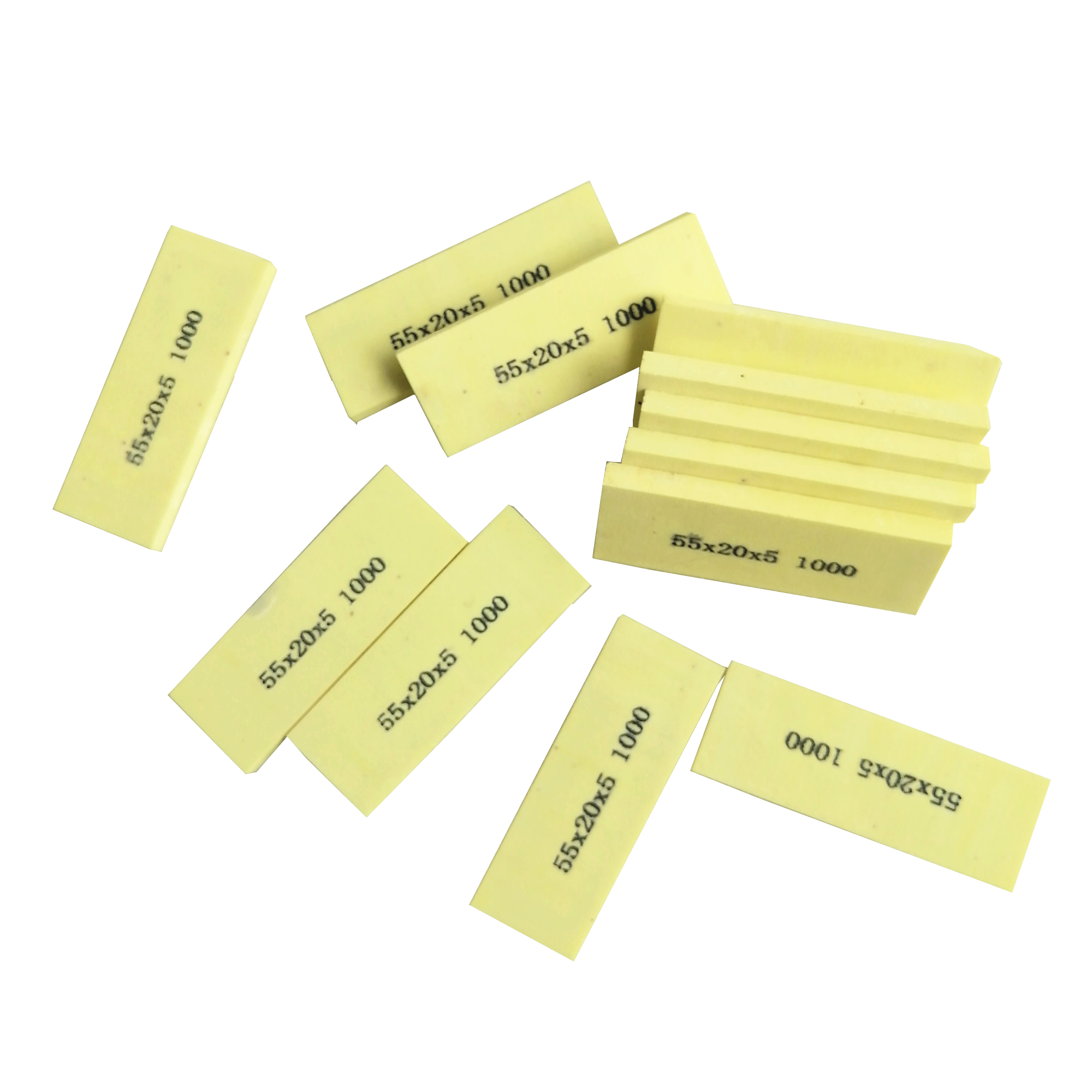

- Shape Rectangular and wedge

- Grain Type White Fused Alumina

- Bonding Vitrified and Resin

- Toughness Medium to High

- Backing None (solid stone)

- Click to View more

X

superfinishing honing stone Price And Quantity

- 300 Piece

- 44.0 USD ($)/Piece

- Individual carton packed with safety instructions

- Precision superfinishing and honing of metal surfaces

- Medium to Low

- up to 35 m/s

- Steel, Stainless Steel, Cast Iron, Hardened Alloys

- Up to Ra 0.05 m

- White or off-white

- Minimum 24 months when stored dry

- -10C to +50C

- High

superfinishing honing stone Product Specifications

- Vitrified and Resin

- Width 6 mm to 50 mm; thickness 3 mm to 20 mm

- White Fused Alumina

- Premium Aluminium Oxide

- Medium to High

- Superfinishing Honing Stone

- 120 to 2000 Grit

- J to M (customizable)

- Al2O3 > 98%, minor SiO2 and Fe2O3

- None (solid stone)

- Custom sizes available; commonly 150mm to 500mm length

- Rectangular and wedge

- Individual carton packed with safety instructions

- Precision superfinishing and honing of metal surfaces

- Medium to Low

- up to 35 m/s

- Steel, Stainless Steel, Cast Iron, Hardened Alloys

- Up to Ra 0.05 m

- White or off-white

- Minimum 24 months when stored dry

- -10C to +50C

- High

Product Description

superfinishing honing stone

High durability for the automotive bearing polishing stones honing sticks, good roughness quality of the workpiece. Widely used for grinding stock absorber piston rods, bearing, and so on in various industries. There are many polishing processes and qualities for your choice.

| Automotive Bearing Polishing Stones Honing Sticks | |

| Length | 50-70mm(can be customized) |

| Width | 6-15mm(can be customized) |

| Thickness | 6-15mm(can be customized) |

| Grit | 400#-6000#(can be customized) |

Advanced Honing for Superior Surfaces

This superfinishing honing stone revolutionizes surface finishing in industries requiring tight tolerances and high-quality finishes. Its high-grade aluminium oxide grains and vitrified or resin bonding ensure outstanding durability and performance, allowing users to reach surface roughness as fine as Ra 0.05 m. Specifically tailored for steel, stainless steel, cast iron, and hardened alloys, it optimizes both productivity and component quality.

Versatile Design and Custom Sizing Options

Adapt to your application's requirements with customizable roll and strip sizes, supporting widths from 6 mm to 50 mm and thicknesses from 3 mm to 20 mm. Available in rectangular and wedge shapes, these stones come in grit sizes from 120 up to 2000, accommodating coarse stock removal through to ultra-fine finishing, fulfilling the needs of distributors, exporters, manufacturers, suppliers, and traders.

FAQ's of superfinishing honing stone:

Q: How should the superfinishing honing stone be used for optimal results?

A: To achieve the best precision and surface finish, mount the honing stone securely in the designated honing or finishing machine, maintain the correct pressure, and operate within the recommended speed of up to 35 m/s. Always follow the supplied safety instructions and use appropriate coolant or lubrication according to your material.Q: What materials are compatible with this honing stone?

A: This stone is specifically engineered for steel, stainless steel, cast iron, and hardened alloys. Its high-purity aluminium oxide grains make it exceptionally effective for hard and tough metals, ensuring a uniform and high-quality finish across compatible substrates.Q: When should I replace the superfinishing honing stone?

A: Replace the honing stone once you observe signs of excessive wear, glazing, reduced cutting performance, or if the desired surface finish can no longer be achieved. Under ideal usage and storage, its shelf life is a minimum of 24 months.Q: Where is the ideal environment to store the honing stones?

A: For maximum shelf life, store the stones in a dry environment at temperatures between -10C and +50C. Proper storage in individual cartons, as provided, shields them from moisture and accidental damage.Q: What benefits does the medium to low porosity offer during honing?

A: Medium to low porosity in the honing stone provides improved structural integrity, consistent performance, and enhanced surface finish consistency, while retaining enough capacity for coolant flow to minimize heat and debris buildup during superfinishing processes.Q: How does the stone's high moisture resistance contribute to its longevity?

A: The high moisture resistance ensures the stone maintains its physical properties and performance, even in humid or challenging environments, preventing degradation and facilitating longer and more reliable operational life for both the stone and honed surfaces.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese