Cylinder Honing Stone

Product Details:

- Hardness Medium to Hard

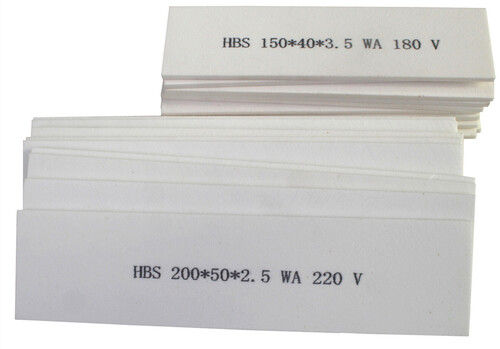

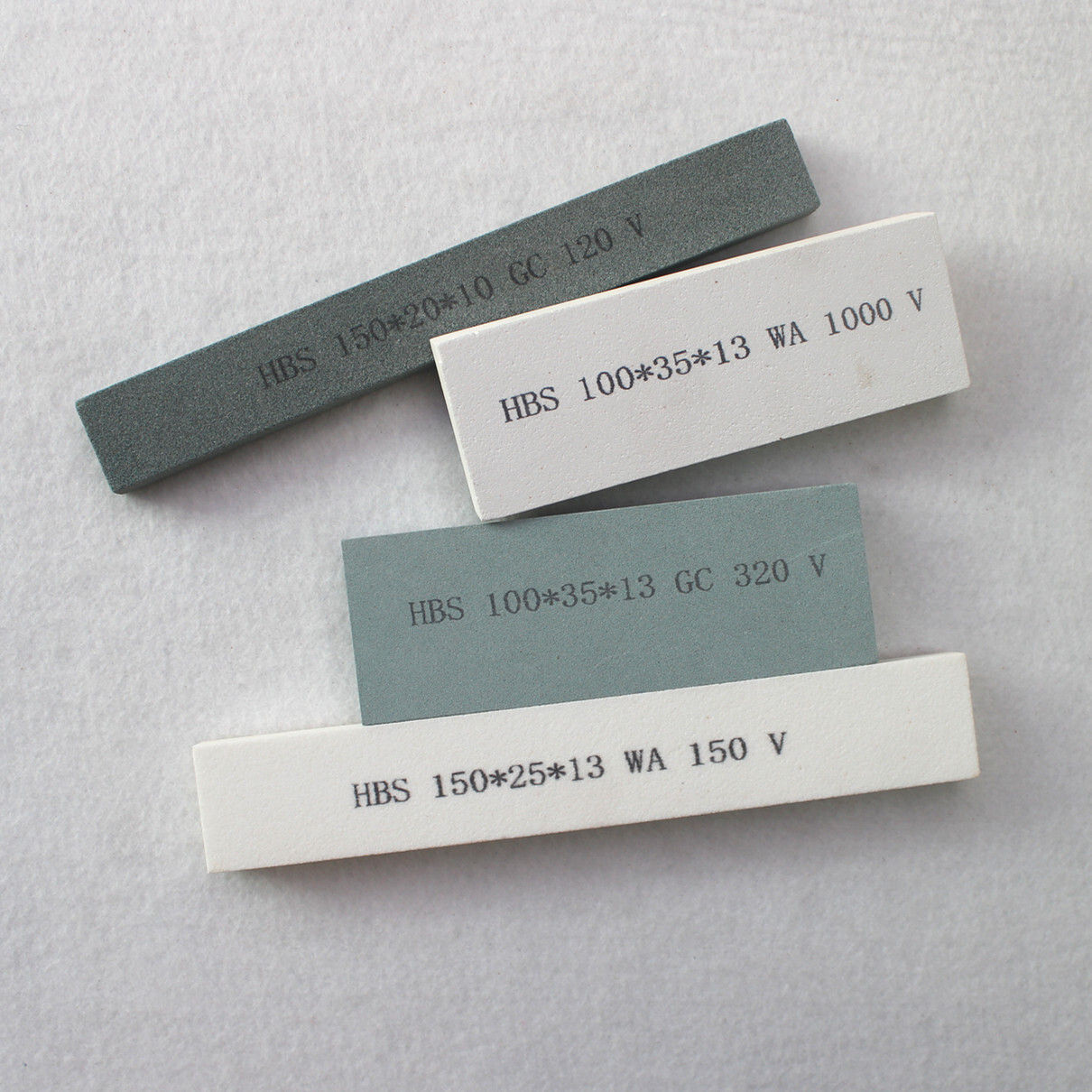

- Shape Rectangular/Bar

- Bonding Vitrified or Resin bond

- Chemical Composition Al2O3 or SiC based materials

- Toughness High durability

- Grain Type Coarse, Medium, Fine

- Material Abrasive Stone (predominantly Aluminum Oxide or Silicon Carbide)

- Click to View more

Cylinder Honing Stone Price And Quantity

- 0.5 USD ($)/Piece

- 300 Millimeter

- Suitable for manual, portable and automatic honing machines

- Up to 15 mm

- Up to 0.3 microns Ra

- Box or Carton packing as per requirement

- Up to 200°C

- Typically Grey or Black

- Used for internal honing and finishing of engine cylinders and hydraulic components

- Long service life depending on usage conditions

Cylinder Honing Stone Product Specifications

- Cylinder Honing Stone

- Standard and custom strips available

- Custom sizes available

- Al2O3 or SiC based materials

- Vitrified or Resin bond

- High durability

- Coarse, Medium, Fine

- Rectangular/Bar

- Medium to Hard

- 60 to 320 grit

- Abrasive Stone (predominantly Aluminum Oxide or Silicon Carbide)

- Suitable for manual, portable and automatic honing machines

- Up to 15 mm

- Up to 0.3 microns Ra

- Box or Carton packing as per requirement

- Up to 200°C

- Typically Grey or Black

- Used for internal honing and finishing of engine cylinders and hydraulic components

- Long service life depending on usage conditions

Product Description

Cylinder Honing Stone

Product Description:

The cylinder honing stone honing stick is widely used in the honing of inner holes in automotive, motorcycle, refrigerator compressor and other industries, can be applied in honing machine of Nagel, Gehring, Dahe, Kunjiang and so on. The specific honing effect will be reached after knowing your detailed request. Different abrasives, bond, hardness and structure will be adopted based on your request.

Green silicon carbide material cylinder honing stone is more used in later honing process for better surface roughness after honing. Relatively, superhard abrasive material honing stone like diamond honin stone or CBN honing stone are used in earlier honing procedures for their fast stock removal ability and long durability.

Normally, to get the best honing effect, we need to know details as below to providemost suitable honing stones.

1) What material is the workpiece to be ground? steel? cast iron? which determines

what abrasives to be applied.

2) Coarse grinding? Fine grinding? semi-finishing?

3) Any requirements for mesh parameters? Coarse mesh or fine mesh pattern?

4) Honing stones size, specification?

5) What machine tools you are using?

| Length(mm) | Width(mm) | Thickness(mm) | Abrasive | Grit |

| 80150 | 615 | 615 | Aluminum oxide Silicon carbide |

80#, 100#, 120#, 150#, 180#, 220#, 240#, 400#, 500#, 600#, 700#, 800#, 1000#... |

Optimal Performance Across Multiple Machines

Cylinder Honing Stones are engineered to work seamlessly with manual, portable, and automatic honing machines. Their versatility allows for efficient honing and finishing across a variety of engine cylinders and hydraulic components, ensuring adaptability to most industrial and automotive applications.

Superior Material and Construction

Manufactured predominantly from Aluminum Oxide or Silicon Carbide, these honing stones are bonded with either vitrified or resin binding, combining high hardness and toughness with lasting durability. Their construction ensures reliable results, even in demanding operational environments and high-temperature conditions.

Custom Sizes and Flexible Packaging

Standard and custom strip sizes are readily available to suit specific application requirements. Products are securely packed in boxes or cartons according to order size, ensuring safe transportation and convenient storage for distributors, exporters, manufacturers, suppliers, and traders.

FAQ's of Cylinder Honing Stone:

Q: How are cylinder honing stones used in finishing engine cylinders and hydraulic components?

A: Cylinder honing stones are installed into compatible honing machines, where they abrade internal surfaces of engine cylinders or hydraulic components. This process creates a precise, smooth finish that enhances component performance and longevity.Q: What benefits do Aluminum Oxide and Silicon Carbide honing stones offer?

A: Aluminum Oxide and Silicon Carbide provide exceptional durability, wear resistance, and efficient material removal, resulting in a consistent, high-quality surface finish. Their robust structure ensures a long service life even under rigorous use.Q: When should I choose a coarse, medium, or fine grain size for my application?

A: Grain size selection depends on the desired surface finish and rate of material removal. Coarse grits are ideal for initial honing and faster stock removal, while finer grits provide smoother finishes, approaching Ra values as low as 0.3 microns.Q: Where can cylinder honing stones be applied?

A: These stones are suitable for use in industries such as automotive manufacturing, hydraulic engineering, and machinery repair. They are compatible with various honing machines found in workshops, factories, and maintenance facilities.Q: What is the process for ordering custom sizes or grit specifications?

A: Custom orders can be placed by specifying the required strip or roll size, shape, and grain size. Distributors and suppliers in China can help tailor the product according to your exact application needs and packaging preferences.Q: What is the typical lifespan of a cylinder honing stone, and what factors influence it?

A: Lifespan varies depending on the frequency and intensity of use, operating temperature, material being honed, and grain size. With proper usage, these stones offer extended longevity due to their high hardness and toughness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese