Honing Stone for Hydraulic Cylinder

80 INR/Piece

Product Details:

- Shape Rectangular / Oblong

- Chemical Composition High Purity Abrasive with Synthetic Additives

- Toughness High Toughness for longer life

- Grain Type Aluminum Oxide / Silicon Carbide

- Bonding Resin / Vitrified Bond

- Backing Steel or Aluminum Holder

- Hardness Medium to Hard (as per application)

- Click to View more

X

Honing Stone for Hydraulic Cylinder Price And Quantity

- 80 INR/Piece

- 500 Piece

- Meets international honing standards

- Wet and dry honing operations

- Long service life under industrial use

- Precision honing of hydraulic cylinders and tubes

- Up to 40 m/s

- 0.1 mm

- Compatible with all standard honing machines

- Up to 200C

- Achieves high precision mirror finish (Ra 0.2-0.6m)

Honing Stone for Hydraulic Cylinder Product Specifications

- Rectangular / Oblong

- High Purity Abrasive with Synthetic Additives

- Abrasive Stone

- High Toughness for longer life

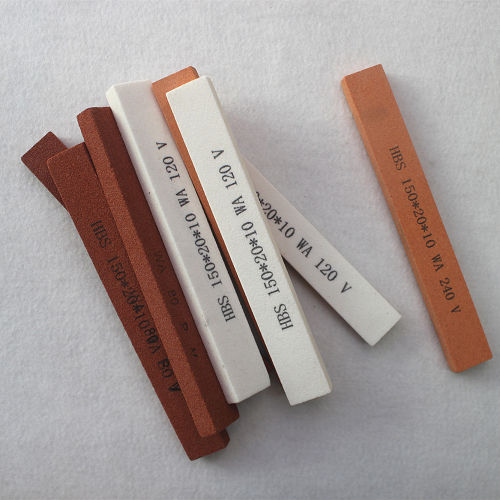

- 150 mm x 15 mm x 5 mm

- Resin / Vitrified Bond

- Aluminum Oxide / Silicon Carbide

- Customizable as per requirement

- Steel or Aluminum Holder

- Medium to Hard (as per application)

- 80, 120, 150, 180, 220, 240, 320, 400, 600 Grit

- Honing Stone for Hydraulic Cylinder

- Meets international honing standards

- Wet and dry honing operations

- Long service life under industrial use

- Precision honing of hydraulic cylinders and tubes

- Up to 40 m/s

- 0.1 mm

- Compatible with all standard honing machines

- Up to 200C

- Achieves high precision mirror finish (Ra 0.2-0.6m)

Product Description

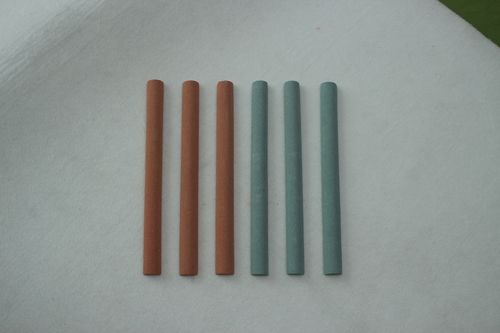

Brief introduction of High Quality Sharpening stones Honing Stone for Hydraulic Cylinder:

Made of silicon carbide, aluminum oxide and vitrified bond through process of mixing, pressing, sintering and cutting.

Vitrified honing stones are preferred when you want fast scale removal and relatively less wear out. With specific application, you could choose vitrified honing stones among brown aluminum oxide, white aluminum oxide, ziconia aluminum oxide, silicon carbide, green silicon carbide abrasives with grits 80-1000.

| Length(mm) | Width(mm) | Height(mm) | Abrasives | |

| 125 | 20 | 6,10 | 60-1200# | A/WA/C/GC |

| 150 | 20,25 | 10,13,16 | ||

| 50 | 25 | |||

| 200 | 30 | 13,20 | ||

| 40 | 20,25 | |||

| 50 | 25 | |||

| 75 | 50 |

| Square sharpening dressing stone | |||

| Length(mm) | Width(mm) | Grit | Abrasives |

| 100 | 6,8,10,13,16 | 60-1200# | A/WA/C/GC |

| 150 | 10,13,16,20,25 | ||

| 200 | 20,25 | ||

| 250 | 25,40 | ||

1. Inner box packing

2. Outer package with standard neutral carton/ color carton.

3. We can design the packing as per customer's request.

4. Wooden case shipping by sea or by air for small quantity

Achieve Superior Surface Finishes

Our honing stone is meticulously crafted to provide high-precision mirror finishes on hydraulic cylinders and tubes. With surface roughness levels between Ra 0.2-0.6m, it ensures optimal performance and reduced friction, extending the lifespan of the cylinder components in demanding industrial settings.

Engineered for Versatility and Durability

Designed for both wet and dry honing operations, the honing stone withstands temperatures up to 200C and has high toughness for a longer operational life. The available grit sizes and customizable dimensions cater to a wide range of applications and cylinder types, guaranteeing compatibility with all standard honing machines.

FAQ's of Honing Stone for Hydraulic Cylinder:

Q: How is the honing stone used for hydraulic cylinders?

A: The honing stone is fitted into standard honing machines and is used to precisely refine the inner surfaces of hydraulic cylinders and tubes, enhancing surface smoothness and geometry. It can be used in both wet and dry honing processes, depending on application requirements.Q: What benefits does precision honing provide for hydraulic cylinders?

A: Precision honing with this stone achieves a high mirror finish (Ra 0.2-0.6m), significantly reducing surface friction, improving sealing capabilities, and extending component life. Consistent high-quality surfaces also help meet stringent industrial performance standards.Q: When should I select a particular grit size for honing?

A: Grit size selection depends on your required surface finish and material removal rate. Coarser grits like 80 or 120 are ideal for rapid material removal, while finer grits such as 320 or 600 are suited for finishing applications where surface smoothness is paramount.Q: Where can the honing stone be applied?

A: This honing stone is suitable for use in all industrial environments requiring the finishing of hydraulic cylinders and tubes, such as manufacturing plants, maintenance workshops, or cylinder refurbishment operations.Q: What is the typical process for honing hydraulic cylinders with this stone?

A: The process involves mounting the correct size and grit honing stone in a compatible machine, applying it to the cylinder's interior surface under controlled speed (up to 40 m/s), and operating under wet or dry conditions, as needed. Continuous monitoring helps achieve the precise tolerance and mirror finish desired.Q: What features contribute to the stone's long service life?

A: Made from high-purity abrasives with synthetic additives and engineered for high toughness and heat resistance, the honing stone offers durability even under rigorous industrial use. Its robust resin or vitrified bonding and backing (steel/aluminum) ensure stability and efficient performance over time.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese