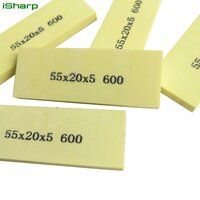

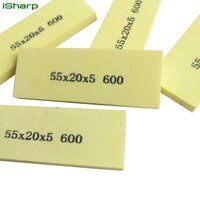

iSahrp Superfinishing stone with high quality

5 USD ($)/Piece

Product Details:

- Chemical Composition Highly refined abrasive oxides with durable ceramic binders

- Toughness High mechanical strength for extended use

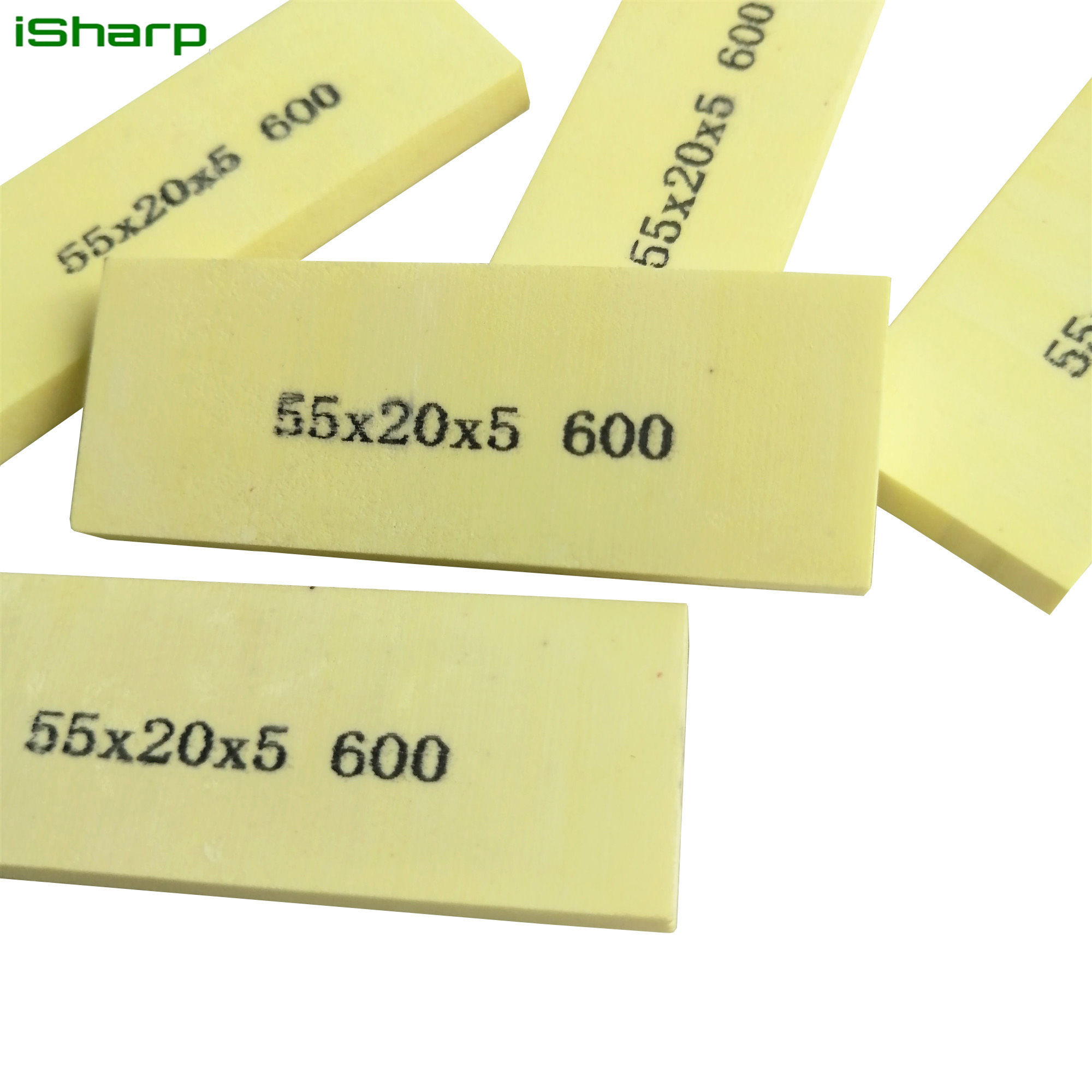

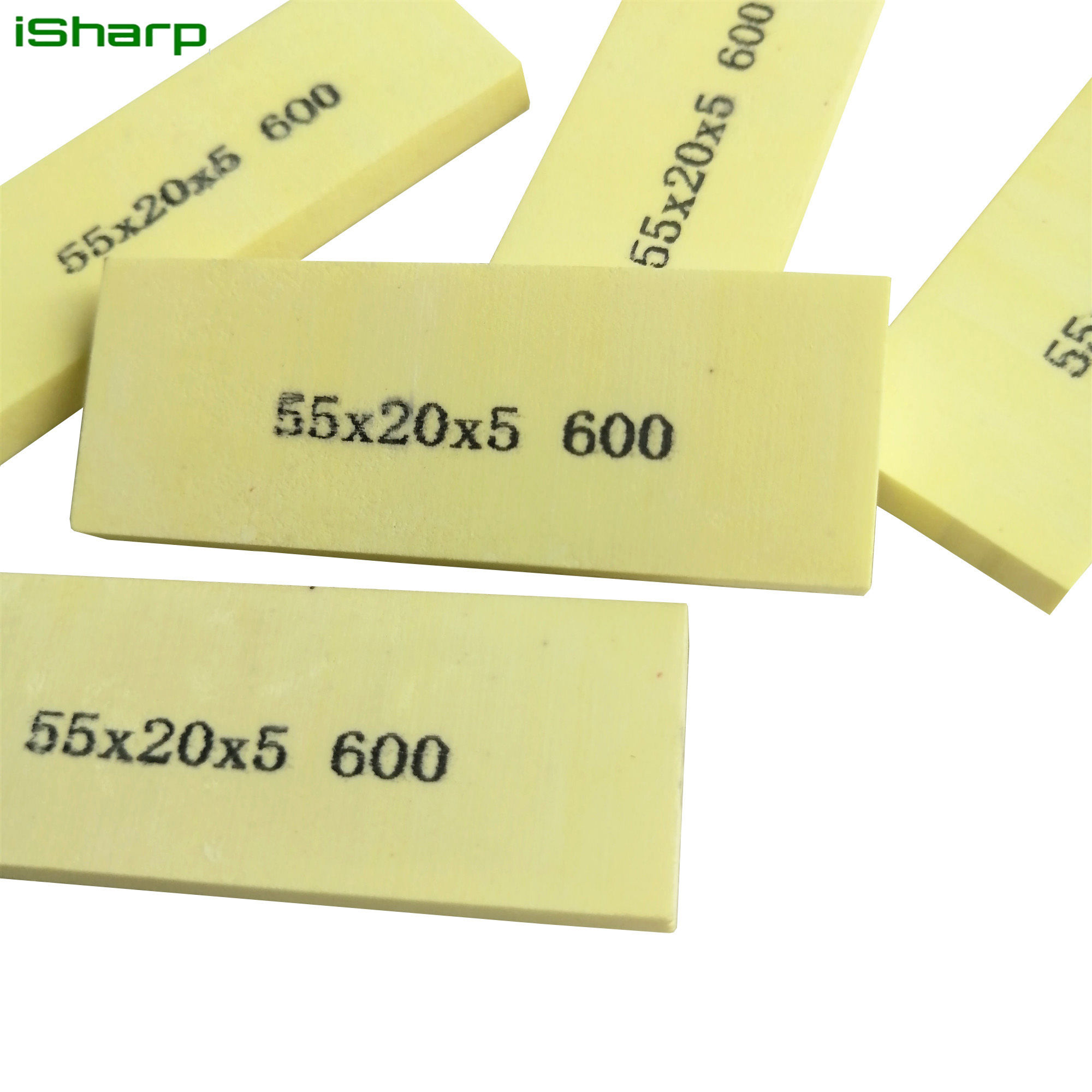

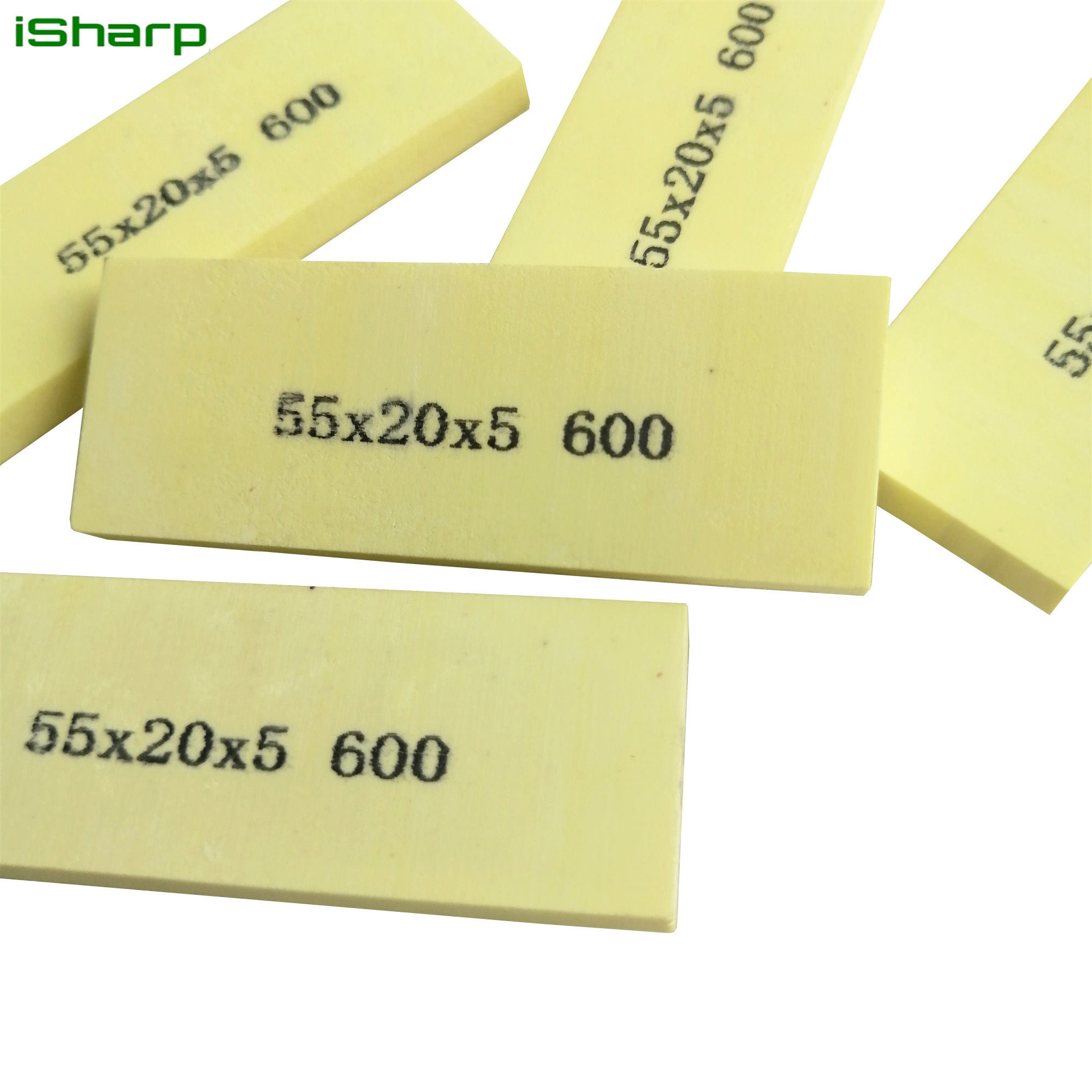

- Shape Rectangular, Square, or Custom profile

- Bonding Resin and Vitrified Bond

- Hardness Medium to Hard (customizable grade)

- Grain Type Aluminium Oxide, Silicon Carbide, CBN

- Backing No backing or optional composite backing for reinforcement

- Click to View more

X

iSahrp Superfinishing stone with high quality Price And Quantity

- 5.00 - 50.00 USD ($)/Piece

- 5 USD ($)/Piece

- 500 Piece

- Finishing and micro-finishing of precision components such as engine parts, shafts, and roller bearings

- 35 m/s

- Grey/White (varies with grain type)

- 24 Months under recommended storage

- Up to Ra 0.02 m achievable

- Up to 250C continuous operation

- Yes, suitable for wet and dry use

iSahrp Superfinishing stone with high quality Product Specifications

- Rectangular, Square, or Custom profile

- Highly refined abrasive oxides with durable ceramic binders

- Available in various custom sizes as per application requirements

- High mechanical strength for extended use

- Superfinishing Stone

- Aluminium Oxide, Silicon Carbide, CBN

- No backing or optional composite backing for reinforcement

- 2504000 grit (customizable)

- Premium Abrasive Grain

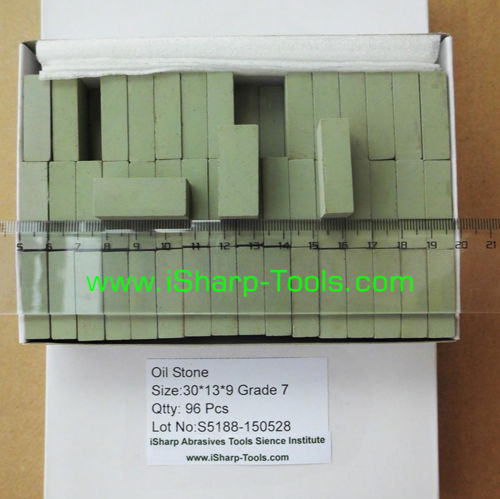

- Standard: 100 mm x 16 mm x 6 mm; other sizes available

- Medium to Hard (customizable grade)

- Resin and Vitrified Bond

- Finishing and micro-finishing of precision components such as engine parts, shafts, and roller bearings

- 35 m/s

- Grey/White (varies with grain type)

- 24 Months under recommended storage

- Up to Ra 0.02 m achievable

- Up to 250C continuous operation

- Yes, suitable for wet and dry use

Product Description

Product Description

1AdvantageHigh durability for the super fine honing stonesgood roughness quality of the workpiece

2UsageWidely used for grinding shock absorber piston rodbearing and so on in various industryThere are many polishing process and quality for your choice

3Different sizesgritshardnessprecision requirements and so on can be madeMinimum size can be 0505mm and the tolerance is controlled within 002mm

Companby Frofile

ISHARP ABRASIVES TOOLS SCIENCE INSTITUTE is a leading grinding solutions provider in China Experienced abrasive engineers constitute a research team Our joint factories develop and manufacture bonded abrasives coated abrasives nonwoven abrasives and abrasive machines Adhering to the concept ofGreen Efficiency Precision we design develop and produce suitable abrasive products machines and offer technology support iSharp helps the users to improve grinding efficiency and quality save grinding cost improve their competitiveness and achieve their value iSharps products include resin bonded cutting disc making machines ceramic bonded grinding wheel making and dressing machines coated abrasive conversion machine flap disc production line mounted flap wheel machines flanged flap wheel making machines curing ovens and related materials and accessories

Expect you enjoy iSharps quality products and outstanding services

FAQ

Q1 Does the oil stone has any safety certifications

A1Yes we have ISO certifications

Q2 Do you accept OEM order

A2 Yes OEM order is accepted We can also help to design label for you

Q3 How to ensure product quality

A3 Raw materials selected strictly control quality from the source Each step has to pass the corresponding quality testing

Exceptional Surface Quality

Designed for superfinishing and micro-finishing, the iSahrp stone produces ultra-smooth surfaces up to Ra 0.02 m. Its use on precision components guarantees reliable consistency and enhanced part longevity by minimizing friction and wear.

Versatile Compatibility and Configuration

With options in grain type, grit size, bonding, and profile, the iSahrp stone accommodates various custom requirements. Available in rectangular, square, and custom shapes, it adapts seamlessly to specific finishing equipment for ideal fit and function.

Durable Performance in Challenging Environments

The stone features high toughness, moisture resistance, and the ability to withstand continuous operating temperatures up to 250C. Resin or vitrified bonds ensure strength in wet or dry conditions, and optional composite backing adds reinforcement if needed.

FAQ's of iSahrp Superfinishing stone with high quality:

Q: How does the iSahrp Superfinishing Stone improve surface finish quality?

A: The stone utilizes highly refined abrasive grains and durable ceramic binders to deliver ultra-fine finishing, achieving surface roughness values as low as Ra 0.02 m for critical precision components.Q: What components are best suited for superfinishing with this stone?

A: Ideal applications include engine parts, shafts, and roller bearings, where micro-finishing supports reduced friction, longer lifespan, and superior operational characteristics.Q: When should the iSahrp stone be used in the finishing process?

A: It is most effective during the final stage of manufacturing or refurbishment, after initial grinding or machining, to achieve the required micro-finish and enhance surface integrity.Q: Where can these superfinishing stones be supplied or exported from?

A: They are manufactured, distributed, and exported from China by various suppliers, traders, and export partners globally to meet regional industrial requirements.Q: What grain types and sizes are available for customization?

A: Customers can select between aluminium oxide, silicon carbide, or CBN grains, with grit sizes ranging from 250 to 4000 to suit each specific application's finishing needs.Q: How does the stone withstand moist or high-temperature conditions?

A: Its moisture resistance and engineered bonding allow both wet and dry operation, and continuous temperature resistance up to 250C ensures stability and safety in demanding environments.Q: What are the benefits of using iSahrp Superfinishing Stones in production lines?

A: Benefits include consistently smooth surface finishes, reduced part wear, enhanced lifespan, adaptability to custom sizes and shapes, and reliable performance during intensive industrial use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese