iSharp sulfurized honing stone

80 INR/Piece

Product Details:

- Grain Type SiC (Silicon Carbide)

- Chemical Composition Silicon carbide, sulfur, bonding agents

- Hardness Medium to Hard (as per application)

- Toughness High durability

- Bonding Sulfurized resin bond

- Shape Rectangular and custom

- Material Sulfurized abrasive (silicon carbide, aluminum oxide blend)

- Click to View more

X

iSharp sulfurized honing stone Price And Quantity

- 80 INR/Piece

- 500 Piece

- Up to 0.2 Ra

- Optimized for lubricant retention

- Box or as required

- Up to 180°C depending on bond

- Suitable for honing oil and water-based coolants

- Black / Dark Green

- Precision honing for engine cylinders, hydraulic tubes, and other metal components

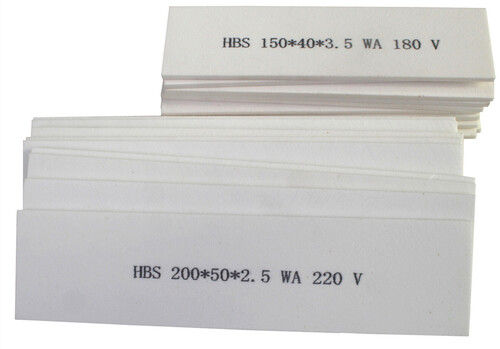

iSharp sulfurized honing stone Product Specifications

- Honing Stone

- Medium to Hard (as per application)

- Silicon carbide, sulfur, bonding agents

- As per requirement, standard 7 x 1/2 x 1/4

- Sulfurized abrasive (silicon carbide, aluminum oxide blend)

- 100 to 1200 Grit

- SiC (Silicon Carbide)

- Custom sizes available

- Rectangular and custom

- Sulfurized resin bond

- High durability

- Up to 0.2 Ra

- Optimized for lubricant retention

- Box or as required

- Up to 180°C depending on bond

- Suitable for honing oil and water-based coolants

- Black / Dark Green

- Precision honing for engine cylinders, hydraulic tubes, and other metal components

Product Description

Product Name iSharp sulfurized honing stone

Brand iSharp

Origin Zhengzhou China

Company Profile

iSharp Abrasives Tools Science Institute Is a leading grinding solutions provides from 1991 We have been in this abrasive filed more than 20 years We put a lot of time and energy into creasing tailored abrasive solutions to meet your needs and exceed your expectationsOur products include the cutting disc production line coated abrasive belt conversion line flap disc production line and mounted flap wheel production line Expect these we also have different products such as the cutting disc flap disc oil stone and grinding wheel

Our products has exported to many countries such as Russia America Germany Italy Ukraine Singapore Brail Mexico Poland And so on Besides we also have built business relationship with some famous company in this field such as Klingspor Deerfos Sunmight CGW and so on Having been innovating the cutting disc and grinding wheel industry for over 15 years you can count on our products to perform consistently

FAQ

1 who are we

We are based in Henan China start from 2013sell to Domestic Market2000Western Europe1300Mid East1000Eastern Europe1000North America900South Asia700Southeast Asia600Southern Europe500Central America500Oceania500Africa500South America300Eastern Asia200 There are total about 301500 people in our office

2 how can we guarantee quality

Always a preproduction sample before mass production

Always final Inspection before shipment

3what can you buy from us

grinding wheel making machineflap disc machinecoated abrasive machineryabrasive toolscutting discs

4 why should you buy from us not from other suppliers

Experienced abrasives engineers constitute a research team from 1991 Adhering to the Green Efficiency Precision concept we design develop and produce suitable abrasive products provide a complete grinding technology services

5 what services can we provide

Accepted Delivery Terms FOBCFRCIFCPTExpress Delivery

Accepted Payment CurrencyUSDEURJPYCADAUDHKDGBPCNYCHF

Accepted Payment Type TTLCDP DAWestern UnionCash

Language SpokenEnglishChinese

Precision Honing for Industrial Demands

Designed for engine cylinders, hydraulic tubes, and assorted metal components, the iSharp sulfurized honing stone delivers outstanding surface finishes while maximizing efficiency. Its blend of silicon carbide and aluminum oxide, paired with a sulfurized resin bond, ensures high toughness and adaptability to challenging environments up to 180C.

Versatile Application and Superior Compatibility

Supporting a wide range of metalworking operations, iSharp honing stones are suitable for both honing oils and water-based coolants, catering to diverse industrial practices. With customizable shapes and grain sizes, the tool adapts to specific honing needs and maintains lubricant retention for enhanced process stability.

FAQ's of iSharp sulfurized honing stone:

Q: How do I use the iSharp sulfurized honing stone for best results?

A: For optimal performance, use the iSharp honing stone with the recommended lubricant-either honing oil or water-based coolant-and select the appropriate grit size for your required surface finish. Ensure the stone is mounted securely in your honing machine, and adjust pressure and speed settings according to the material and application.Q: What are the main benefits of a sulfurized honing stone compared to conventional stones?

A: Sulfurized honing stones, like those from iSharp, offer improved lubricant retention due to their optimized porosity, leading to smoother finishes and prolonged stone life. The robust blend of silicon carbide and aluminum oxide delivers high cutting efficiency and wear resistance, reducing downtime and replacement costs.Q: When should I choose the dark green or black color honing stone?

A: The color (black or dark green) reflects specific grain and bonding characteristics tailored to various metal types and finish requirements. For most applications, either can be used based on availability and the manufacturer's guidance, ensuring compatibility with your workpiece material and desired surface finish.Q: Where can iSharp honing stones be applied in industrial processes?

A: iSharp honing stones are ideal for precision honing of engine cylinders, hydraulic tubes, and other metal components that demand fine surface finishes. They are widely used in automotive, aerospace, and hydraulic system manufacturing environments.Q: What is the process for selecting the right grain size and shape?

A: Selecting a grain size from 100 to 1200 grit depends on the desired surface finish-coarser grit for rough stock removal and finer grit for smoother finishes. Shapes (rectangular or custom) and sizes can be tailored to fit your honing machine and application requirements; consult with an iSharp distributor or supplier for specific recommendations.Q: How does the sulfurized resin bond affect honing performance?

A: The sulfurized resin bond provides enhanced thermal stability up to 180C and contributes to the stone's hardness and toughness. This ensures consistent abrasive action, reduced risk of stone glazing, and suitability for extended honing cycles under high loads.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese