Honing stone for engine cylinder

Product Details:

- Hardness Medium to Hard

- Grain Type Abrasive Grain

- Toughness High Impact Resistance

- Shape Rectangular

- Chemical Composition Al2O3 (Aluminum Oxide)

- Backing Steel Backing

- Bonding Resin Bond

- Click to View more

Honing stone for engine cylinder Price And Quantity

- 500 Piece

- 30 INR/Piece

- Up to 500°C

- 3.9 g/cm³

- 10 mm

- 2 years under recommended storage conditions

- Suitable for automobile engine cylinder surface finishing and honing

- Produces fine and smooth bore surface

- Compatible with all standard engine honing machines

- Low, designed for extended usage

Honing stone for engine cylinder Product Specifications

- Custom as per requirement

- Abrasive Grain

- Engine Cylinder Honing Stone

- 80-120 grit

- Medium to Hard

- Steel Backing

- High-grade Aluminum Oxide

- 100 mm x 20 mm x 10 mm

- Al2O3 (Aluminum Oxide)

- Resin Bond

- High Impact Resistance

- Rectangular

- Up to 500°C

- 3.9 g/cm³

- 10 mm

- 2 years under recommended storage conditions

- Suitable for automobile engine cylinder surface finishing and honing

- Produces fine and smooth bore surface

- Compatible with all standard engine honing machines

- Low, designed for extended usage

Product Description

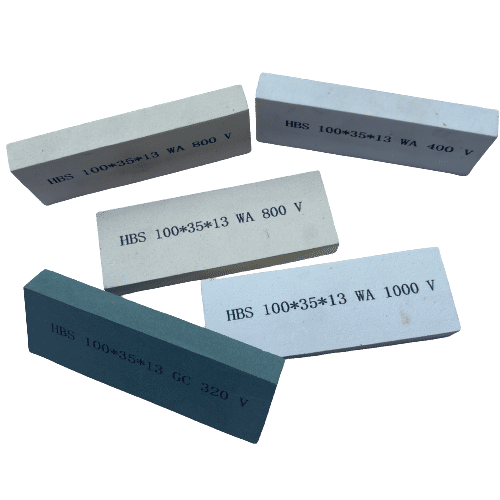

Square sharpening dressing stone

| Length(mm) | Width(mm) | Grit | Abrasives | |

| 100 | 6,8,10,13,16 | 60-1200# | 150 | 10,13,16,20,25 |

| 200 | 20,25 | |||

| 250 | 25,40 |

| Rectangular sharpening dressing stones | ||||

| Length(mm) | Width(mm) | Height(mm) | Abrasives | |

| 125 | 20 | 6,10 | 60-1200# | A/WA/C/GC |

| 150 | 20,25 | 10,13,16 | ||

| 50 | 25 | |||

| 200 | 30 | 13,20 | ||

| 40 | 20,25 | |||

| 50 | 25 | |||

| 75 | 50 | |||

1. Inner box packing

2. Outer package with standard neutral carton/ color carton.

3. We can design the packing as per customer's request.

4. Wooden case shipping by sea or by air for small quantity

Our Service:

1.OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your questions in 24 hours.

Our products has exported to many countries, such as Russia, America, Germany, Italy, Ukraine, Singapore, Brail, Mexico, Poland, And so on. Besides, we also have built business relationship with some famous company in this field, such as Klingspor, Deerfos, Sunmight, CGW and so on. Having been innovating the cutting disc and grinding wheel industry for over 15 years, you can count on our products to perform consistently.

Optimal Surface Finish for Engine Cylinders

Our engine cylinder honing stone is designed to consistently deliver a high-quality, smooth bore surface, essential for peak engine performance. With high-grade aluminum oxide construction and precise abrasive grain sizing, it ensures minimal wear and exact finishing, reducing friction and promoting engine longevity.

Robust Compatibility and Versatility

Compatible with all standard engine honing machines, this honing stone meets the demands of various automobile workshops and manufacturers. The product's rectangular shape, customizable strip sizes, and steel backing add to its adaptability for different honing requirements.

Engineered for Endurance and Efficiency

With a low wear rate and ability to withstand temperatures up to 500C, this honing stone is specially crafted for long-term, high-performance use. Its medium to hard hardness, strong resin bond, and high-density structure enable it to operate efficiently, sustaining quality and shape throughout extended honing processes.

FAQ's of Honing stone for engine cylinder:

Q: How does this honing stone improve engine cylinder surface finishing?

A: This honing stone utilizes high-grade aluminum oxide with precise abrasive grains (80-120 grit), resulting in a fine, smooth, and uniform bore surface. Such a finish minimizes surface friction, leading to better engine sealing, reduced oil consumption, and improved overall engine performance.Q: What is the recommended process for using the honing stone with engine cylinders?

A: Install the honing stone into any standard engine honing machine, ensuring it is securely fastened. Follow the machine's operating guidelines for pressure, feed, and lubrication. Gradually hone the cylinder to achieve the desired finish, periodically checking for smoothness and bore size as per manufacturer specifications.Q: When should I replace the honing stone for optimal performance?

A: Although designed for extended usage with a low wear rate, it is advisable to replace the stone when you notice a decline in finish quality or significant reduction in size. Under standard conditions, the shelf life is 2 years if stored properly.Q: Where can the honing stone be applied apart from automobile engine cylinders?

A: While primarily intended for automobile engine cylinders, this honing stone can also be used for finishing and polishing cylindrical surfaces in other machinery and equipment compatible with standard honing machines.Q: What benefits does the high hardness and toughness of this stone offer?

A: The medium to hard hardness combined with high impact resistance ensures the stone maintains its shape and effectiveness even during prolonged, intensive honing operations, reducing downtime and replacement frequency.Q: How should the honing stone be stored to maximize its shelf life?

A: To preserve its 2-year shelf life, the honing stone should be stored in a dry, cool environment away from direct sunlight and corrosive substances, preferably in its original packaging until ready for use.Q: What advantages does the resin bond provide during the honing process?

A: The resin bond enhances grain adhesion and flexibility, enabling the stone to deliver consistent cutting performance and a uniform finish, even under high-temperature applications up to 500C.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese