Aluminium Oxide Grinding Stone Sharpening Stones for Diamond Wheel Dressing

Product Details:

- Toughness High toughness, suitable for wheel dressing

- Grain Type Brown Fused Alumina (BFA)

- Backing No backingsolid stone

- Hardness Medium to High (as per application)

- Chemical Composition Al2O3 > 95%

- Bonding Vitrified Bond

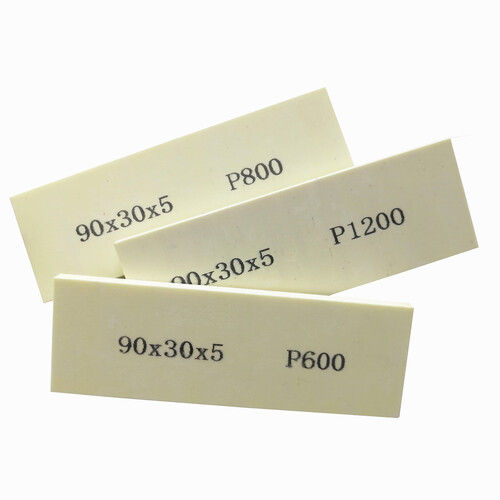

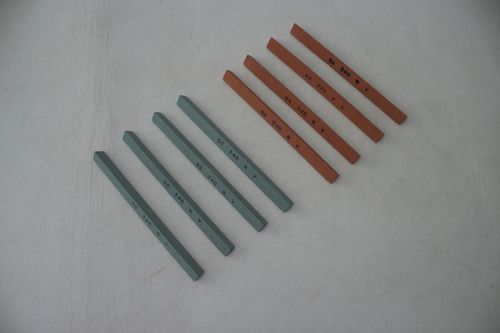

- Shape Round, rectangular, square

- Click to View more

Aluminium Oxide Grinding Stone Sharpening Stones for Diamond Wheel Dressing Price And Quantity

- 500 Piece

- 0.40 - 4.00 USD ($)/Piece

- 0.4 USD ($)/Piece

- Controlled according to wheel specification

- Up to 1000C

- 2.22.8 g/cm

- Light brown or grey

- Diamond wheel dressing and sharpening

- Works with all types of diamond and CBN wheels

- Industrial grade

- Individual boxes or bulk packing

Aluminium Oxide Grinding Stone Sharpening Stones for Diamond Wheel Dressing Product Specifications

- Brown Fused Alumina (BFA)

- No backingsolid stone

- High toughness, suitable for wheel dressing

- Available from F24 to F1000

- Medium to High (as per application)

- Grinding Stone Sharpening Stone

- Aluminium Oxide

- Round, rectangular, square

- Standard strips and custom dimensions

- Custom sizes available upon request

- Vitrified Bond

- Al2O3 > 95%

- Controlled according to wheel specification

- Up to 1000C

- 2.22.8 g/cm

- Light brown or grey

- Diamond wheel dressing and sharpening

- Works with all types of diamond and CBN wheels

- Industrial grade

- Individual boxes or bulk packing

Product Description

The Aluminium oxide grinding stone sharpening stones for diamond wheel dressing are especially for truing diamond grinding wheel in glass industry to expose new diamonds to maintain the sharpness for glass edge processing.

Different sizes, grit, hardness and so on can be made as your request. The precision can be reached to Thicness(-0.15/,+0.15mm), Width(-0.2, -0.5mm) and Length(-0.5, +1mm).

Product Parameters

| Aluminium Oxide Grinding Stone Sharpening Stones for Diamond Wheel Dressing | ||||

| Thickness(mm) | Width(mm) | Length(mm) | Grit | Abrasives |

| 2.0 | 30/50 | 120/150/180/200 | #150, #180, #220 | White Aluminum Oxide |

| 2.5 | 30/50 | 120/150/180/200 | #150, #180, #220 | White Aluminum Oxide |

| 3.0 | 30/50 | 120/150/180/200 | #150, #180, #220 | White Aluminum Oxide |

| 3.5 | 30/50 | 120/150/180/200 | #150, #180, #220 | White Aluminum Oxide |

| 4.2 | 30/50 | 120/150/180/200 | #150, #180, #220 | White Aluminum Oxide |

| 4.9 | 30/50 | 120/150/180/200 | #150, #180, #220 | White Aluminum Oxide |

| 5.0 | 30/50 | 120/150/180/200 | #150, #180, #220 | White Aluminum Oxide |

| 5.1 | 30/50 | 120/150/180/200 | #150, #180, #220 | White Aluminum Oxide |

| 9.0 | 30/50 | 120/150/180/200 | #150, #180, #220 | White Aluminum Oxide |

Packaging & Shipping

For the packing of aluminium oxide grinding stone sharpening stones for diamond wheel dressing, we will use shrink plastick package first, then packed in corrugated cartons, finally it's export standard wooden case to secure the dressing stones during sea shipping to ensure the goods you receive is good and well. For the shipping, sea shipping, air shipping and railway shipping are all supported. iSharp Abrasives will use its optimized operation process to save your waiting time not only in production step, but also the shipping step. That's also the special advantage of iSharp Abrasives.

Our Advantages

1. Factory direct, best price you will get for the aluminium oxide grinding stone sharpening stones for diamond wheel dressing

2. Manufacturing since 1958, very experienced engineer will provide tailor-made solutions for you

3. Strict inline quality check and final inspection before shipment to ensure quality products

4. Scientific management system to ensure each batch products traceable

5. Steady quality to become your long-term business partner

6. Business is negotiable and with iSharp Abrasives, we are flexible to meet your requirement as much as we can.

Company Profile

ISHARP ABRASIVES TOOLS SCIENCE INSTITUTE is a leading grinding solutions provider in China. Experienced abrasive engineers constitute a research team. Our joint factories develop and manufacture bonded abrasives, coated abrasives, non-woven abrasives and abrasive machines. Adhering to the concept of"Green, Efficiency, Precision", we design, develop and produce suitable abrasive products, machines and offer technology support. iSharp helps the users to improve grinding efficiency and quality, save grinding cost, improve their competitiveness and achieve their value. iSharp's products include resin bonded cutting disc making machines, ceramic bonded grinding wheel making and dressing machines, coated abrasive conversion machine, flap disc production line, mounted flap wheel machines, flanged flap wheel making machines, curing ovens and

related materials and accessories.

Expect you enjoy iSharp's quality products and outstanding services!

Ultimate Compatibility with Diamond and CBN Wheels

These sharpening stones are engineered to work seamlessly with any diamond or CBN grinding wheels, ensuring effective dressing and sharpening for a broad range of industrial tasks. The solid construction and optimized abrasive grade provide reliable performance across diverse environments.

Precision and Customization for Every Application

Offered in a variety of shapes, strip sizes, and grain specifications (F24-F1000), each sharpening stone can be tailored to your specific needs. Whether you require standard shapes or customized dimensions, we deliver solutions that match exacting requirements with consistent quality.

Robust Performance in Demanding Conditions

Manufactured using high-purity aluminium oxide, these stones maintain structural integrity at elevated temperatures-up to 1000C. The vitrified bond and controlled porosity ensure uniform performance, making them suitable for rigorous usage in industrial settings.

FAQ's of Aluminium Oxide Grinding Stone Sharpening Stones for Diamond Wheel Dressing:

Q: How do I use aluminium oxide grinding stones for diamond wheel dressing?

A: Use the grinding stone by gently applying it against the diamond or CBN wheel under recommended operating conditions. This process removes debris and restores the wheel's sharpness without damaging its surface.Q: What benefits do industrial-grade aluminium oxide stones offer for sharpening?

A: These stones provide high toughness, efficient material removal, and precise wheel dressing, thanks to their controlled porosity, hard vitrified bond, and superior abrasive quality. They ensure longer wheel life and consistent sharpening results.Q: When should I consider replacing my sharpening stone?

A: You should replace the stone if there is excessive wear, loss of shape, or diminished effectiveness during dressing. Regular inspection helps maintain optimal tool performance and surface finish.Q: Where can I use aluminium oxide grinding stones for sharpening tasks?

A: These stones are ideal for use in industrial settings, tool rooms, manufacturing plants, and workshops that utilize diamond or CBN wheels for grinding and finishing operations.Q: What is the process for ordering custom sizes or shapes?

A: Simply specify your required dimensions, shape, and grain size when placing an order. We accommodate custom requests with tailored production and flexible packaging options.Q: Are these sharpening stones suitable for high-temperature applications?

A: Yes, the stones are engineered to withstand temperatures up to 1000C, making them suitable for heavy-duty and high-temperature grinding or dressing environments.Q: What type of packaging is available for these grinding stones?

A: The grinding stones can be supplied in individual boxes for convenience or bulk packed for larger orders, depending on your operational requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese