Honing Stones for Grinding Piston Rod of Shock Absorber

Product Details:

- Backing Steel / Brass / Fiber backing

- Bonding Vitrified / Resin Bond

- Chemical Composition High-purity alumina / silicon carbide with proprietary binds

- Shape Rectangular, Wedge, Custom Profiles

- Toughness Optimized for precision honing applications

- Grain Type Monocrystalline / Polycrystalline

- Hardness Medium to Hard (as per application)

- Click to View more

Honing Stones for Grinding Piston Rod of Shock Absorber Price And Quantity

- 80 INR/Piece

- 500 Piece

Honing Stones for Grinding Piston Rod of Shock Absorber Product Specifications

- Steel / Brass / Fiber backing

- 60, 80, 120, 180, 220, 320 (Other sizes on request)

- Vitrified / Resin Bond

- Piston Rod Honing Stone

- Customizable as per application, typically 6 x 25 mm or 6 x 32 mm

- Rectangular, Wedge, Custom Profiles

- High-purity alumina / silicon carbide with proprietary binds

- Optimized for precision honing applications

- Standard and as per client requirement

- Aluminum Oxide / Silicon Carbide

- Monocrystalline / Polycrystalline

- Medium to Hard (as per application)

Product Description

Product Description

The ultra-precision sharpening honing stones are widely used for grinding shock absorber piston rod, bearing and so on in various industry. There are many polishing process and quality for your choice.

Product Parameters

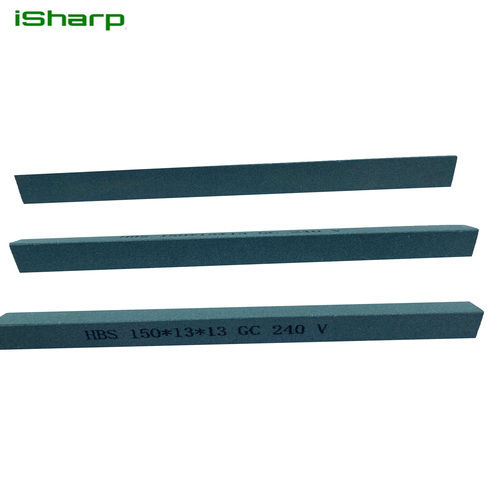

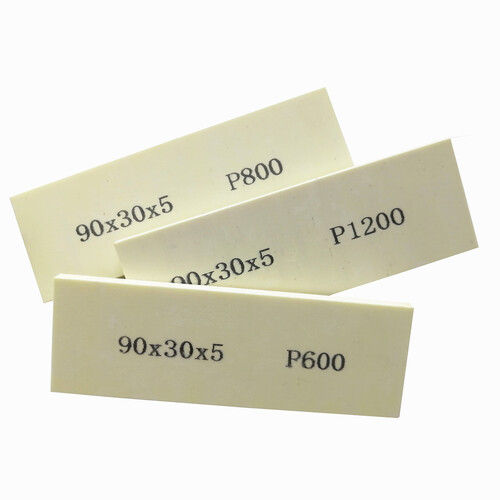

| Ultra-precision Sharpening Honing Stones for Grinding Shock Absorber Piston Rod | |

| 50-150mm(can be customized) | |

| Width | 6-13mm(can be customized) |

| Grit | #80-#6000(can be customized) |

| Abrasives | A,WA,C,GC(can be customized) |

ultra-precision sharpening honing stones for grinding shock absorber piston rod, we will use shrink plastick package first, then packed in corrugated cartons, finally it's export standard wooden case to secure the dressing stones during sea shipping to ensure the goods you receive is good and well.

For the shipping, sea shipping, air shipping and railway shipping are all supported. iSharp Abrasives will use its optimized operation process to save your waiting time not only in production step, but also the shipping step. That's also the special advantage of iSharp Abrasives.

Superior Surface Finishing Solutions

With our honing stones, automotive manufacturers can achieve consistent and ultra-smooth surface finishes up to Ra 0.2 m on piston rods. These stones are available in various grit sizes and profiles, ensuring precise adaptation to your application and delivering repeatable quality for shock absorber components.

Engineered for Versatility and Compatibility

Designed to fit both vertical and horizontal honing machines, our honing stones offer excellent compatibility across diverse industrial setups. They support operational speeds up to 2500 RPM and come with options for standard and custom sizes as well as profiles, ensuring seamless integration into your existing processes.

Durability Meets Precision

Constructed with high-purity materials like aluminum oxide and silicon carbide, and available with steel, brass, or fiber backing, our honing stones exhibit high resilience and reduced wear. Precision-ground edges maintain uniform contact, while sealed packaging preserves product quality during transit and storage.

FAQ's of Honing Stones for Grinding Piston Rod of Shock Absorber:

Q: How do I choose the right honing stone for grinding piston rods of shock absorbers?

A: Selection depends on your desired surface finish, machine compatibility, grit size, and required hardness. Our stones come in various grades and shapes, including customizable options, ensuring an optimal match for your honing process and equipment.Q: What surface finish can these honing stones achieve?

A: Our honing stones can deliver precision surface finishes up to Ra 0.2 m, making them ideal for super-finishing automotive piston rods for shock absorbers.Q: When is it recommended to replace the honing stone during operation?

A: Replace the honing stone when you observe a decline in surface finish quality, reduced material removal efficiency, or excessive wear. Regular monitoring helps maintain consistent honing results.Q: Where can these honing stones be used besides shock absorber piston rods?

A: While primarily designed for automotive shock absorber piston rods, these stones can be adapted for other cylindrical precision honing tasks where high-quality surface finishing is required, depending on the customization of sizes and grades.Q: What are the benefits of using color-coded honing stones?

A: The colors (grey, black, green) indicate different grades, making it easy to identify the appropriate stone for each stage of the honing process. This helps optimize efficiency and consistency in your workflow.Q: How are the honing stones packaged and delivered?

A: Each honing stone is supplied in sealed, protective packaging to ensure safe transit and preserve the stone's integrity before use. We ship globally as a manufacturer, supplier, and distributor based in China.Q: What backing materials and bonding options are available for these honing stones?

A: Our stones are available with steel, brass, or fiber backing, and are bonded using either vitrified or resin binds. This ensures optimal resilience, toughness, and performance tailored to your application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese