CBN honing stone for cylinder polishing dressing

Product Details:

- Grain Type CBN (Cubic Boron Nitride)

- Shape Rectangular / Wedge / Custom

- Chemical Composition CBN with metallic bond matrix

- Backing Steel / Aluminum alloy backing

- Hardness Highfor industrial cylinder honing

- Toughness Excellent (suitable for rigorous cylinder dressing)

- Bonding Metal Bond

- Click to View more

CBN honing stone for cylinder polishing dressing Price And Quantity

- 0.4 USD ($)/Piece

- 500 Piece

- Standard (100%) or customized

- As per requirement (customizable)

- Extra long due to high abrasion resistance

- Excellentstable in wet honing environments

- Suitable for cast iron, steel, and alloy cylinder liners

- Cylinder bore polishing and dressing

- Mechanical clamp or adhesive

- High, improving cooling efficiency

- Mirror-like (Ra 0.20.4m achievable)

- Up to 600C

- Available on size, grit, and formulation

CBN honing stone for cylinder polishing dressing Product Specifications

- Rectangular / Wedge / Custom

- CBN (Cubic Boron Nitride)

- CBN with metallic bond matrix

- Cubic Boron Nitride (CBN)

- #80#600 (customizable)

- Customized as per cylinder size

- Honing Stone for Polishing & Dressing

- Excellent (suitable for rigorous cylinder dressing)

- Metal Bond

- Standard and custom dimensions available

- Steel / Aluminum alloy backing

- Highfor industrial cylinder honing

- Standard (100%) or customized

- As per requirement (customizable)

- Extra long due to high abrasion resistance

- Excellentstable in wet honing environments

- Suitable for cast iron, steel, and alloy cylinder liners

- Cylinder bore polishing and dressing

- Mechanical clamp or adhesive

- High, improving cooling efficiency

- Mirror-like (Ra 0.20.4m achievable)

- Up to 600C

- Available on size, grit, and formulation

Product Description

Brief introduction of Honing stone for cylinder liner made of super hard material

The CBN super abrasive honing stones for cylinder polishing dressing is suitable for marine diesel engines automobile internal combustion engines air compressors coal mine hydraulic supports etc After the vitrified honing stone plateau honing slide honing helical slide honing etc the Rpk Rk etc is effectively reduced the engine runningin time is reduced and the ideal cross hatch and parameters comes Provides excellent oil retention performance improves the oil film distribution on the inner surface of the cylinder liner improves the quality of environmental emissions and meets the technical requirements of China V China VI Euro 5 and Euro 6 automobile emission limit

Our CBN super abrasive honing stones for cylinder polishing dressing have been steadily used on honing machine tools such as Gehring Sunnen Nagel Kunjiang Dahe etc

You can find our CBN super abrasive honing stones for cylinder polishing dressing are widely applied in engine cylinder liners of various brands like MercedesBenz Carter John Deere Fiat Cummins Steyr International Harvester Iveco Voith Daimler AGCO Sinotruk Weichai Yuchai FAWDE ChaoYang Diesel etc

Product Parameters

K Series Honing Stones

Honing Unit K3 K4 K5 K6 K8 K10 K12 K16 K20 AK20 AK30

Stone Length 15 15 18 19 32 32 45 57 63 63 63

Bore diameter 253 34 45 56 68 895 9513 1316 1619 1932 3240

B Series Honing Stones

Honing Unit B8 B10 B12 B14 B16 B20 AB20 AB30

Stone Length 47 47 60 70 85 95 95 95

Bore diameter 68 895 9513 9513 1316 1619 1932 3240

L Series Honing Stones

Honing Unit L3 L4 L5 L6 L8 L10 L12 L16 L20

Stone Length 25 25 32 35 57 57 88 114 114

Bore diameter 193 34 45 56 68 895 9513 1316 1632

General Size

Grit 5060 6070 7080 80100 100120 120140 140170 170200

FEPA B301 or D301 B251 or D251 B213 or D213 B181 or D181 B151 or D151 B126 or D126 B107 or D107 B91 or D91

Grit 200230 230270 270325 325400 W40 W28 W20 W14

FEPA B76 or D76 B64 or D64 B54 or D54 B46 or D46 M63 M40 M25 M16

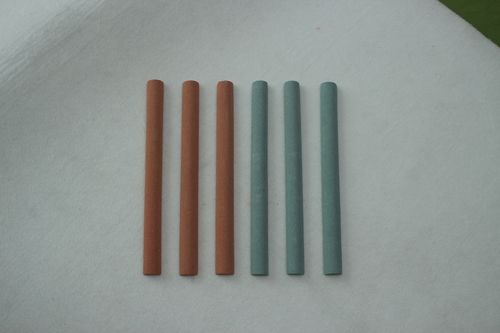

Detailed Photos

Diamond Honing Stones 5jpgCBN png

Our Advantages

1 Factory direct best price you will get for the HBS diesel locomotive cylinder honing stones

2 Manufacturing since 1958 very experienced engineer will provide tailormade solutions for you

3 Strict inline quality check and final inspection before shipment to ensure quality products

4 Scientific management system to ensure each batch products traceable

5 Steady quality to become your longterm business partner

6 Business is negotiable and with iSharp Abrasives we are flexible to meet your requirement as much as we can

After Sales Service

Any problem will be answered in 24hours to cooperate with you to solve the problem we are always together with you

Company Profile

ISHARP ABRASIVES TOOLS SCIENCE INSTITUTE iSharp Abrasives Tools Science Institute is a manufacturer of precision grinding tools since 1991 Its subsidiary Tianjin HongBaoShi Abrasives Manufacturing Co Ltd was established in 1958 For more than 50 years the ceramic honing stone resin honing stone wood powder honing stone diamond honing stone CBN honing stone and so on manufactured by Tianjin HongBaoShi have consistent stable quality Honed cylinder with quality cross hatch meets the automobile emission limit standard of China V China VI Euro 5 Euro 6 etc in the honing stones field Tianjin HongBaoShi Abrasives has the largest market share in China and has been the supplier for some biggest cylinder making factories In the international markets there are also wide applications in the series of super fine honing stones dressing stones mold and die sharpening stones ceramic fiber stone and so on

Expect you enjoy iSharps quality products and outstanding services

High-Performance Materials for Advanced Cylinder Honing

Crafted from industrial-grade Cubic Boron Nitride and strengthened with a metal bond, these honing stones offer remarkable hardness and toughness. Their ability to resist abrasion and maintain effectiveness, even at elevated temperatures and in moist environments, guarantees consistent and precise honing results on a wide range of cylinder liners.

Ultimate Customization for Every Honing Application

With a variety of grain sizes (#80-#600), customizable dimensions, and compatibility with standard and tailored backing materials, our CBN honing stones align perfectly with your cylinder size and surface requirements. We provide flexible minimum order quantities and specialized formulations to meet your unique production needs.

Superior Mirror-Like Finishing & Longevity

Designed to yield a mirror-quality finish with Ra values as low as 0.2-0.4m, these honing stones enhance engine efficiency and durability. Their high thermal conductivity keeps cylinders cool during operations, while the robust bond matrix extends stone life under rigorous industrial use.

FAQ's of CBN honing stone for cylinder polishing dressing:

Q: How does a CBN honing stone improve the cylinder bore polishing process?

A: CBN honing stones utilize Cubic Boron Nitride grains bonded in a metallic matrix, providing exceptional abrasion resistance and hardness. This enables efficient removal of material and fine polishing, resulting in a precise and mirror-like bore surface (Ra 0.2-0.4m), essential for optimal engine performance.Q: What types of materials are compatible with these CBN honing stones?

A: These honing stones are specifically designed for use on cast iron, steel, and alloy cylinder liners. Their robust construction ensures effective polishing and dressing across various industrial cylinder materials.Q: When should a CBN honing stone be chosen over other abrasive types?

A: Select a CBN honing stone when you require superior wear resistance, high thermal stability (up to 600C), and consistently fine surface finishes. They are ideal for high-volume, heavy-duty applications where extended working life and precise results matter.Q: Where can these honing stones be applied, and do they perform well in wet honing environments?

A: Our CBN honing stones are ideal for engine rebuilding workshops, automotive and machinery manufacturing, and industrial cylinder liner production. They are engineered with excellent moisture resistance and remain stable in wet honing or coolant-rich environments.Q: What is the process for mounting and customizing the CBN honing stones?

A: Mounting is straightforward, with options for mechanical clamping or adhesive fixation. Customization is available for dimensions, grain size, grit concentration, shape, and formulation-ensuring optimal fit and performance for your specific honing machinery and requirements.Q: How does high thermal conductivity benefit the honing process?

A: High thermal conductivity rapidly disperses heat generated during honing, preventing excessive temperature rise. This ensures stable honing conditions, reduces thermal deformation, and prolongs both the tool and liner lifespan.Q: What are the main benefits of using these CBN honing stones for cylinder liner dressing and polishing?

A: Benefits include achieving ultra-smooth, mirror-like finishes, exceptional tool lifespan, compatibility with a range of cylinder liner materials, operational stability in wet or high-temperature environments, and the ability to tailor specifications to your unique project requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese