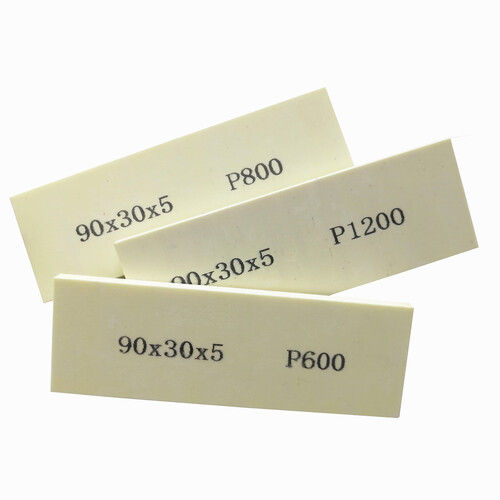

Dressing Sticks Sharpening Stone for Diamond & CBN Wheel

50 INR/Piece

Product Details:

- Grain Type Single or Multiple grain

- Toughness High

- Hardness Medium to Hard

- Shape Rectangular, Square, Strip

- Bonding Vitrified Bond

- Chemical Composition High purity Al2O3 or SiC

- Backing None, solid stone

- Click to View more

X

Dressing Sticks Sharpening Stone for Diamond & CBN Wheel Price And Quantity

- 3000 Piece

- 50 INR/Piece

- Grey, Green, Black (depends on material)

- Fine/Coarse depending on grit

- Up to 1000C

- Controlled for enhanced dressing action

- Unlimited under standard storage conditions

- 2.7 3.1 g/cm

- Box, Polywrap

- Suitable for resin, vitrified, and metal bonded wheels

- Used for dressing, cleaning, and conditioning Diamond and CBN wheels

Dressing Sticks Sharpening Stone for Diamond & CBN Wheel Product Specifications

- None, solid stone

- High purity Al2O3 or SiC

- Vitrified Bond

- Customized on demand

- Aluminum Oxide (Al2O3) / Silicon Carbide (SiC)

- Rectangular, Square, Strip

- 36 to 120 grit

- Sharpening & Dressing Stick

- Medium to Hard

- 150 mm x 25 mm x 25 mm, 200 mm x 25 mm x 25 mm (Custom sizes available)

- High

- Single or Multiple grain

- Grey, Green, Black (depends on material)

- Fine/Coarse depending on grit

- Up to 1000C

- Controlled for enhanced dressing action

- Unlimited under standard storage conditions

- 2.7 3.1 g/cm

- Box, Polywrap

- Suitable for resin, vitrified, and metal bonded wheels

- Used for dressing, cleaning, and conditioning Diamond and CBN wheels

Product Description

Use cartons and pallets for packaging, delivery time is 30-45 days, according to your order quantity.

We export sharpening stones to Malaysia, Indonesia, Vietnam, Thailand, Belgium, Germany, and many other countries. our product with high quality, we cooperated with the MSC company of America.

Q4: What is the payment term?

A4: T/T, Irrevocable LC at sight, Western Union, Paypal.

A4: T/T, Irrevocable LC at sight, Western Union, Paypal.

Q5.What information I need to provide before I buy the grinding stone?

A5.We need to know the product size, grit, abrasives and usage, then we can recommend suitable products to you.

Exceptional Versatility and Durability

Dressing Sticks Sharpening Stones are engineered for use with Diamond and CBN wheels across numerous bonding types, making them a flexible solution for manufacturers and industrial users. Manufactured from hard-wearing materials such as Aluminum Oxide and Silicon Carbide, they perform reliably under high temperatures, offering precise and consistent dressing every time.

Tailored for Optimal Wheel Maintenance

With a variety of grit sizes and finish options, these dressing sticks allow for both coarse and fine maintenance, ensuring grinding wheels stay clean, sharp, and in optimal working condition. The sticks' controlled porosity further enhances their capability to dress and condition wheels efficiently, prolonging wheel life and improving performance.

FAQ's of Dressing Sticks Sharpening Stone for Diamond & CBN Wheel:

Q: How are Dressing Sticks Sharpening Stones used with Diamond and CBN wheels?

A: To use a dressing stick, you gently apply it to the rotating surface of the Diamond or CBN wheel. The abrasive action cleans, conditions, and reshapes the wheel, removing clogs and glazing so that it maintains optimal sharpness and performance.Q: What sizes and shapes are available for the dressing sticks?

A: Standard sizes include 150 mm x 25 mm x 25 mm and 200 mm x 25 mm x 25 mm, with custom sizes and shapes such as rectangular, square, and strip available upon request. This ensures the perfect fit for different wheel types and applications.Q: When should I use a dressing stick on my grinding wheel?

A: Use a dressing stick whenever the Diamond or CBN wheel becomes glazed, clogged, or loses cutting efficiency. Regular dressing maintains wheel performance and extends its service life.Q: Where are these dressing sticks applicable?

A: These sharpening stones are suitable for use in industrial settings including manufacturing plants, tool rooms, and workshops requiring precision grinding and wheel maintenance. They function effectively with resin, vitrified, and metal-bonded wheels.Q: What is the process for dressing a Diamond or CBN wheel?

A: The process involves gently pressing the dressing stick against the running wheel surface. Controlled porosity and the selected grit grade of the stick help to remove debris, open up the wheel's surface, and restore its cutting ability in a short time.Q: What benefits do dressing sticks provide for Diamond and CBN wheels?

A: Dressing sticks help maintain wheel sharpness, improve grinding efficiency, and extend the usable life of expensive Diamond and CBN wheels. Their high durability and unlimited shelf life make them cost-effective and dependable tools for wheel care.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese