iSharp dressing sticks for diamond grinding wheel

0.4 USD ($)/Piece

Product Details:

- Backing No backing; solid stick

- Bonding Vitrified and resin bond options

- Shape Rectangular, square, and custom-shaped sticks

- Grain Type Monocrystalline and polycrystalline

- Hardness Medium to hard grades

- Chemical Composition AlO, SiC

- Toughness High fracture toughness to resist breakage

- Click to View more

X

iSharp dressing sticks for diamond grinding wheel Price And Quantity

- 500 Piece

- 0.4 USD ($)/Piece

- White, green, and dark gray as per grain type

- Up to 1000°C

- Manual or machine-assisted dressing

- Suitable for dressing diamond & CBN grinding wheels

- Individual shrink-wrapped or boxed

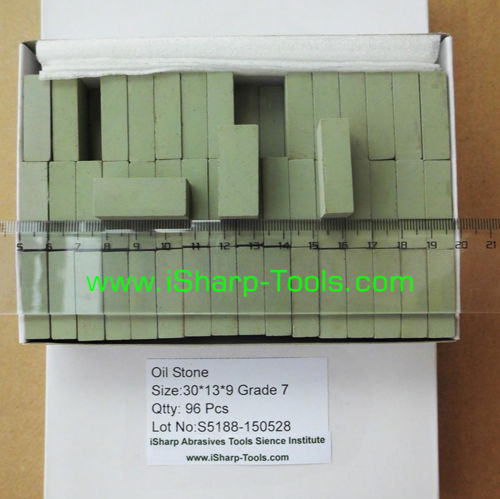

iSharp dressing sticks for diamond grinding wheel Product Specifications

- Dressing stick for diamond grinding wheel

- High fracture toughness to resist breakage

- Medium to hard grades

- Standard strip size: 6 x 1/2 x 1/2 and custom dimensions

- AlO, SiC

- High-purity aluminum oxide & silicon carbide

- Rectangular, square, and custom-shaped sticks

- Available in grit sizes from 80 to 1000

- No backing; solid stick

- Vitrified and resin bond options

- Standard and customized sizes available, typically ranging from 6mm to 25mm thickness

- Monocrystalline and polycrystalline

- White, green, and dark gray as per grain type

- Up to 1000°C

- Manual or machine-assisted dressing

- Suitable for dressing diamond & CBN grinding wheels

- Individual shrink-wrapped or boxed

Product Description

Company Profile

ISHARP ABRASIVES TOOLS SCIENCE INSTITUTE is a leading grinding solutions provider in China Experienced abrasive engineers constitute a research team Our joint factories develop and manufacture bonded abrasives coated abrasives nonwoven abrasives and abrasive machines Adhering to the concept ofGreen Efficiency Precision we design develop and produce suitable abrasive products machines and offer technology support iSharp helps the users to improve grinding efficiency and quality save grinding cost improve their competitiveness and achieve their value iSharps products include resin bonded cutting disc making machines ceramic bonded grinding wheel making and dressing machines coated abrasive conversion machine flap disc production line mounted flap wheel machines flanged flap wheel making machines curing ovens and related materials and accessories

Expect you enjoy iSharps quality products and outstanding services

FAQ

1 who are we

We are based in Henan China start from 2013sell to Domestic Market2000Western Europe1300Mid East1000Eastern Europe1000North America900South Asia700Southeast Asia600Southern Europe500Central America500Oceania500Africa500South America300Eastern Asia200 There are total about 301500 people in our office

2 how can we guarantee quality

Always a preproduction sample before mass production

Always final Inspection before shipment

3what can you buy from us

grinding wheel making machineflap disc machinecoated abrasive machineryabrasive toolscutting discs

4 why should you buy from us not from other suppliers

Experienced abrasives engineers constitute a research team from 1991 Adhering to the Green Efficiency Precision concept we design develop and produce suitable abrasive products provide a complete grinding technology services

5 what services can we provide

Accepted Delivery Terms FOBCFRCIFCPTExpress Delivery

Accepted Payment CurrencyUSDEURJPYCADAUDHKDGBPCNYCHF

Accepted Payment Type TTLCDP DAWestern UnionCash

Language SpokenEnglishChinese

Premium Material and Versatility

Manufactured using high-purity aluminum oxide and silicon carbide, iSharp dressing sticks are built for durability and high fracture toughness. With various shapes, sizes, and bonding options available, users can find the perfect fit for different diamond and CBN wheel profiles. Customization ensures compatibility with diverse machinery and manual dressing techniques.

Efficient Wheel Dressing Solutions

These dressing sticks restore the sharpness and cutting ability of your grinding wheels, removing debris and glazing without causing wheel damage. The sticks' medium to hard grades and monocrystalline or polycrystalline grain types further enhance their performance across multiple applications, ensuring consistent wheel maintenance for improved operational efficiency.

FAQ's of iSharp dressing sticks for diamond grinding wheel:

Q: How do you use iSharp dressing sticks on diamond or CBN grinding wheels?

A: To use iSharp dressing sticks, apply them either manually by holding the stick against the wheel while it rotates or with machine assistance. This process removes embedded debris and restores the wheel's surface, optimizing its grinding capabilities.Q: What are the benefits of using iSharp dressing sticks for grinding wheel maintenance?

A: Using iSharp dressing sticks helps maintain wheel sharpness, extend wheel life, and ensure consistent grinding quality. Their high fracture toughness and material integrity minimize breakage, providing reliable dressing even under demanding conditions.Q: When should a dressing stick be used on a grinding wheel?

A: A dressing stick should be used when the grinding wheel shows signs of loading, glazing, or reduced cutting efficiency. Regular dressing prevents wheel clogging, maintains performance, and supports precise grinding outcomes.Q: Where are iSharp dressing sticks commonly utilized?

A: These dressing sticks are widely used in tool rooms, manufacturing plants, and maintenance facilities, particularly where diamond and CBN grinding wheels are employed. They are suitable for both professional and industrial settings requiring high-precision grinding.Q: What types of iSharp dressing sticks are available based on grain type and bonding?

A: iSharp offers dressing sticks in monocrystalline and polycrystalline grain types with vitrified and resin bonding options. Colors like white, green, and dark gray indicate the grain composition, suited for specific dressing tasks and wheel materials.Q: What is the recommended process for selecting the right dressing stick size and hardness?

A: Select the dressing stick based on your grinding wheel's dimensions, desired finish, and level of contamination. Choose the appropriate grit size (between 80 and 1000), thickness, and grade (medium to hard) according to your application and dressing frequency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese