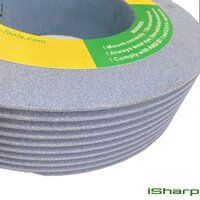

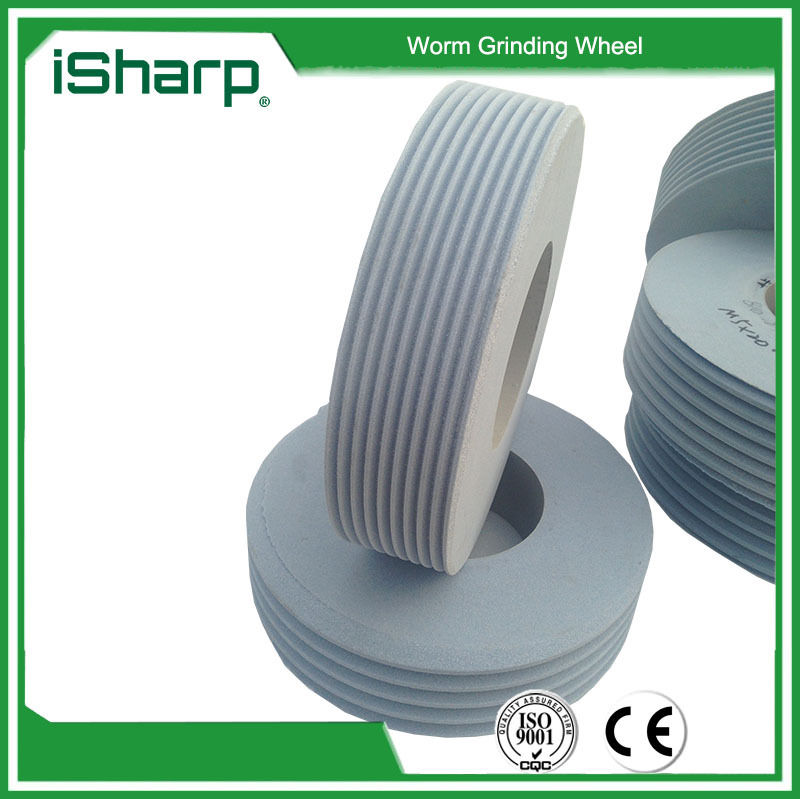

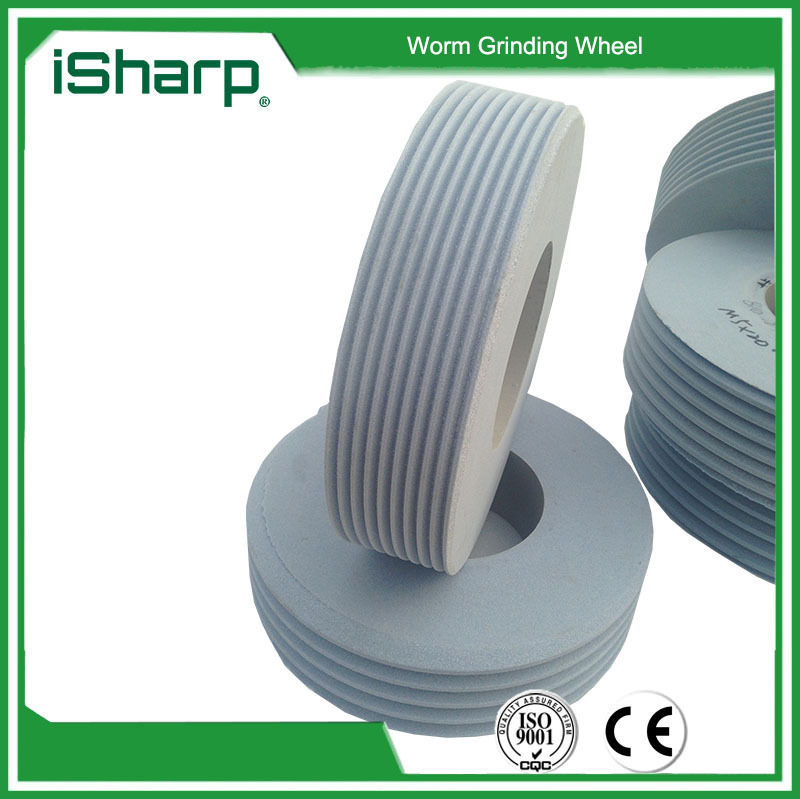

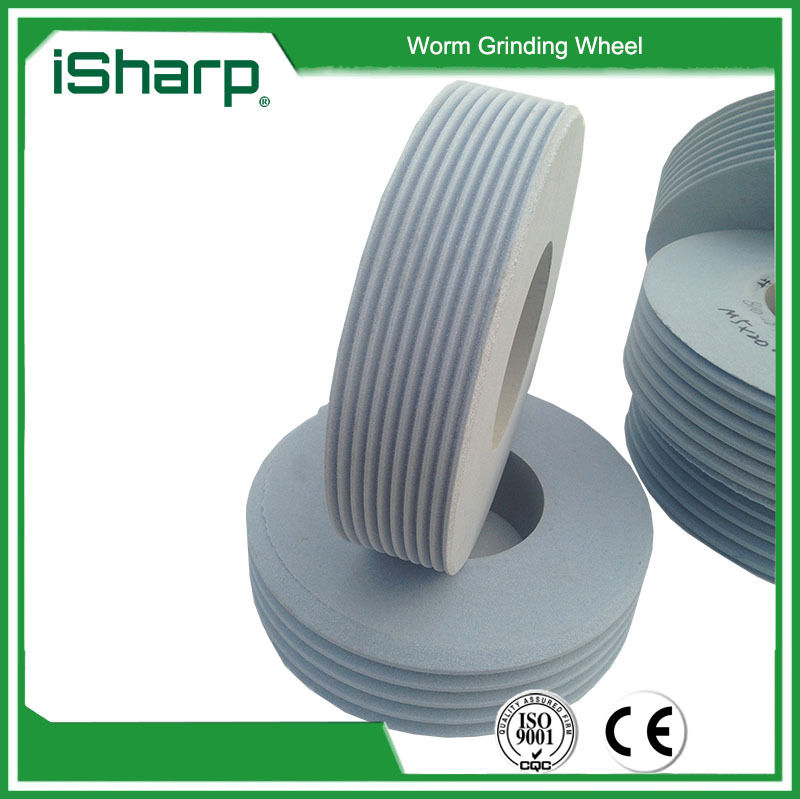

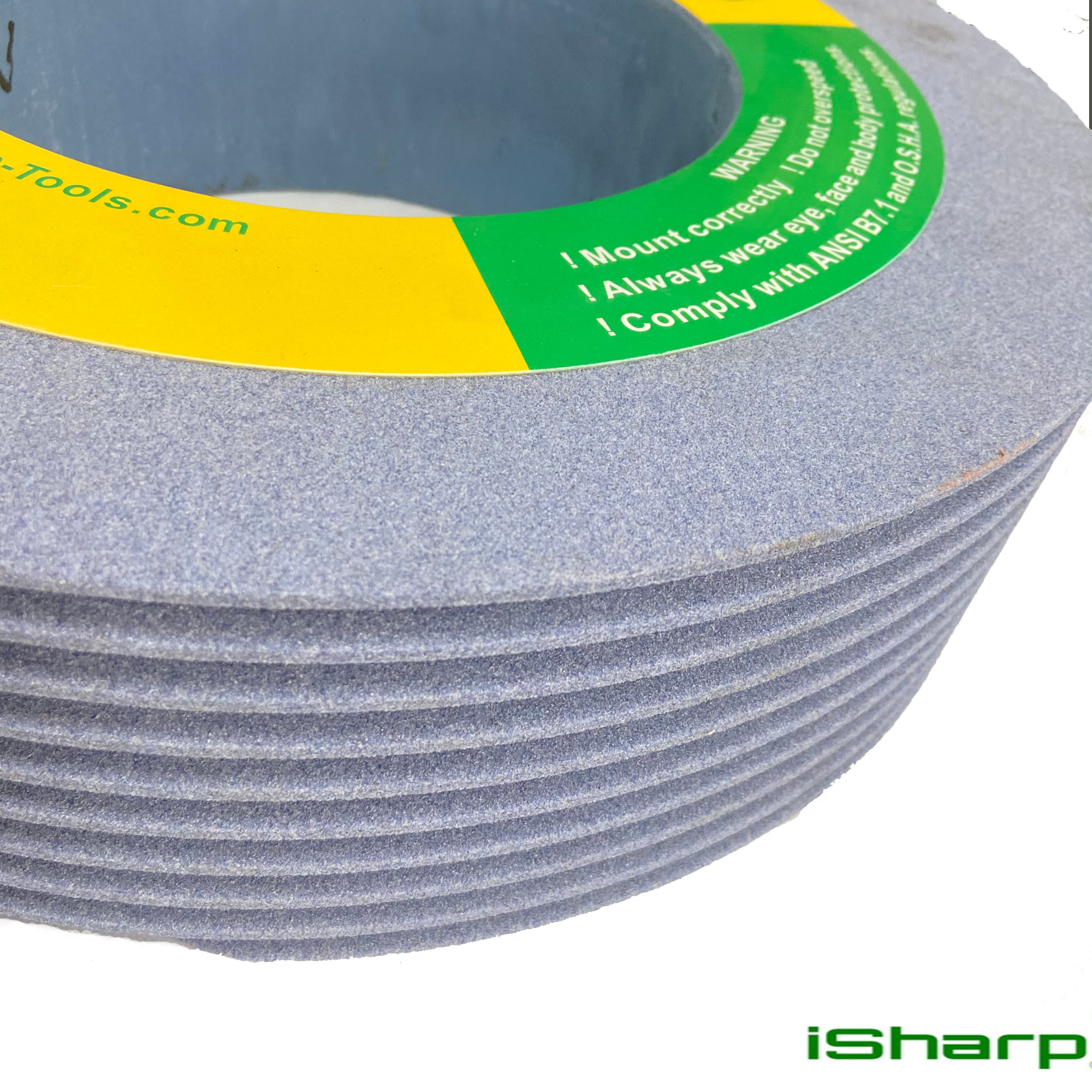

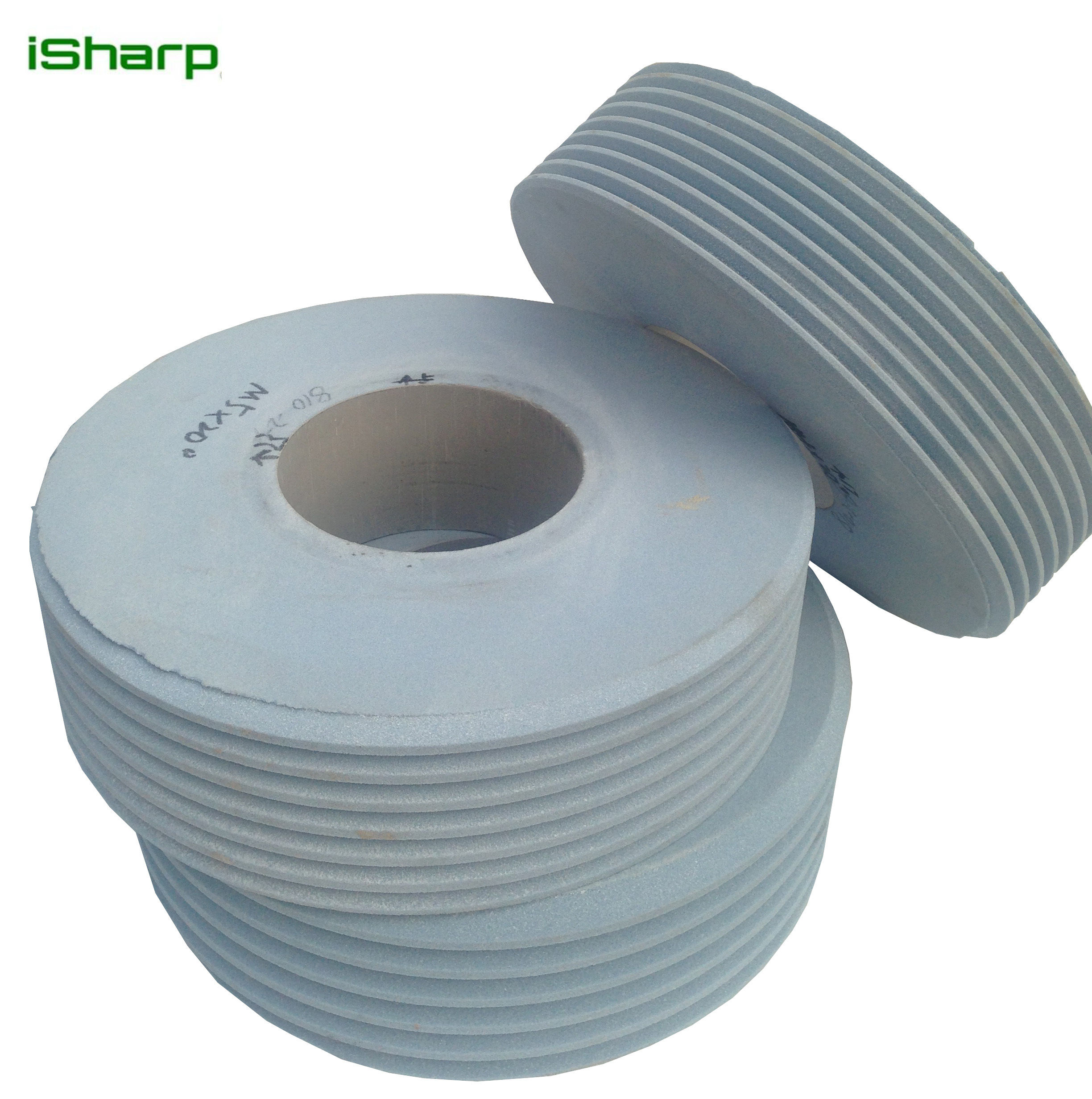

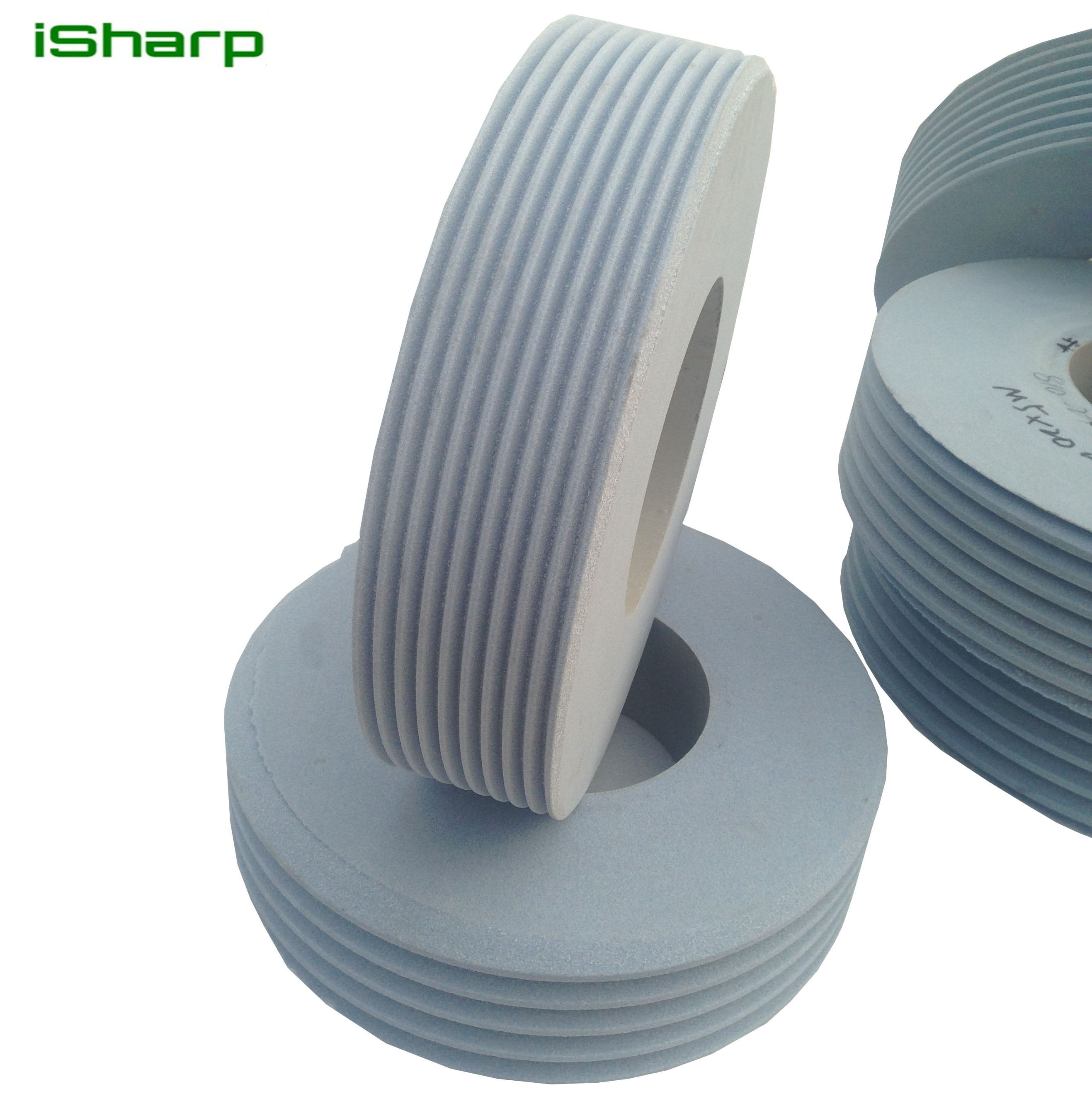

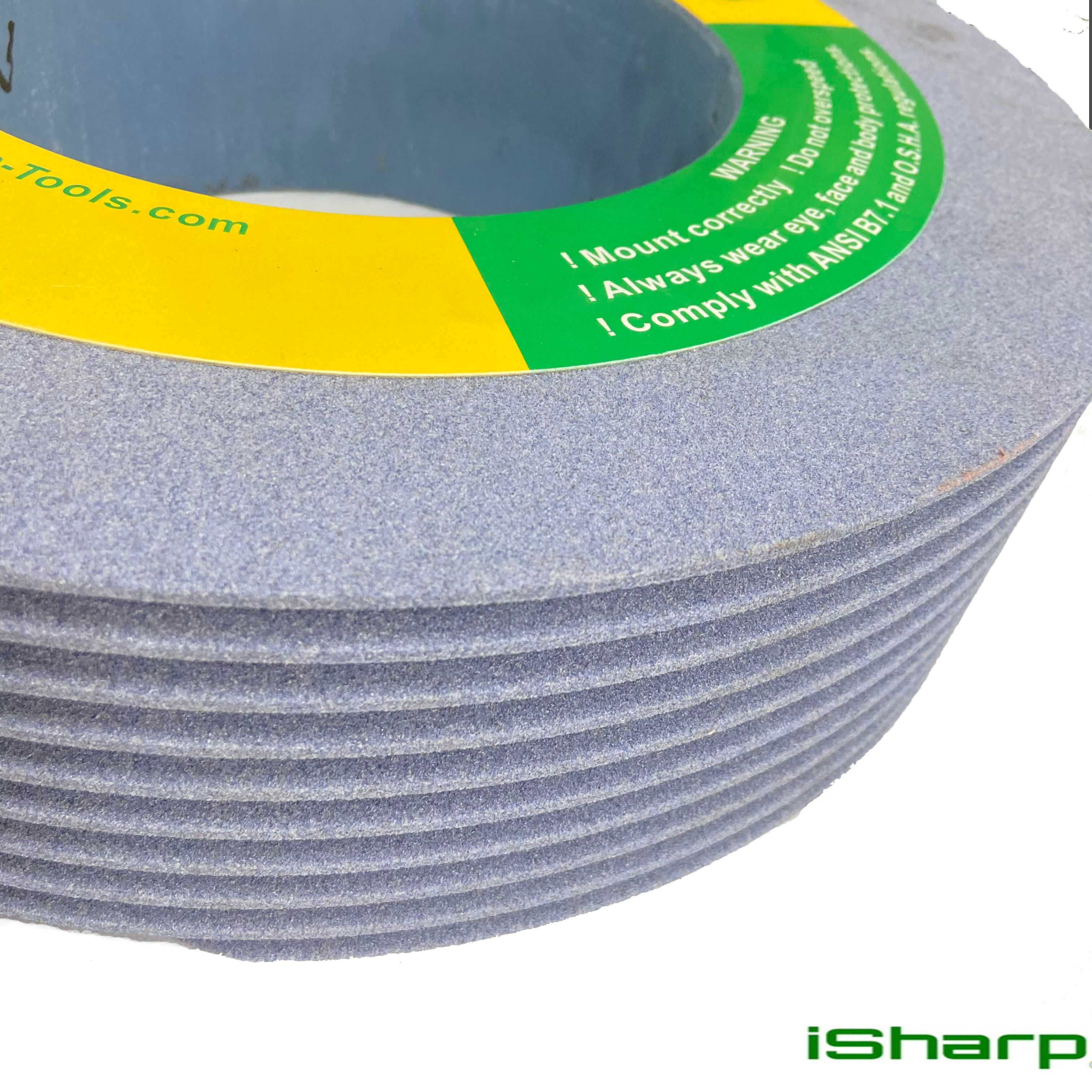

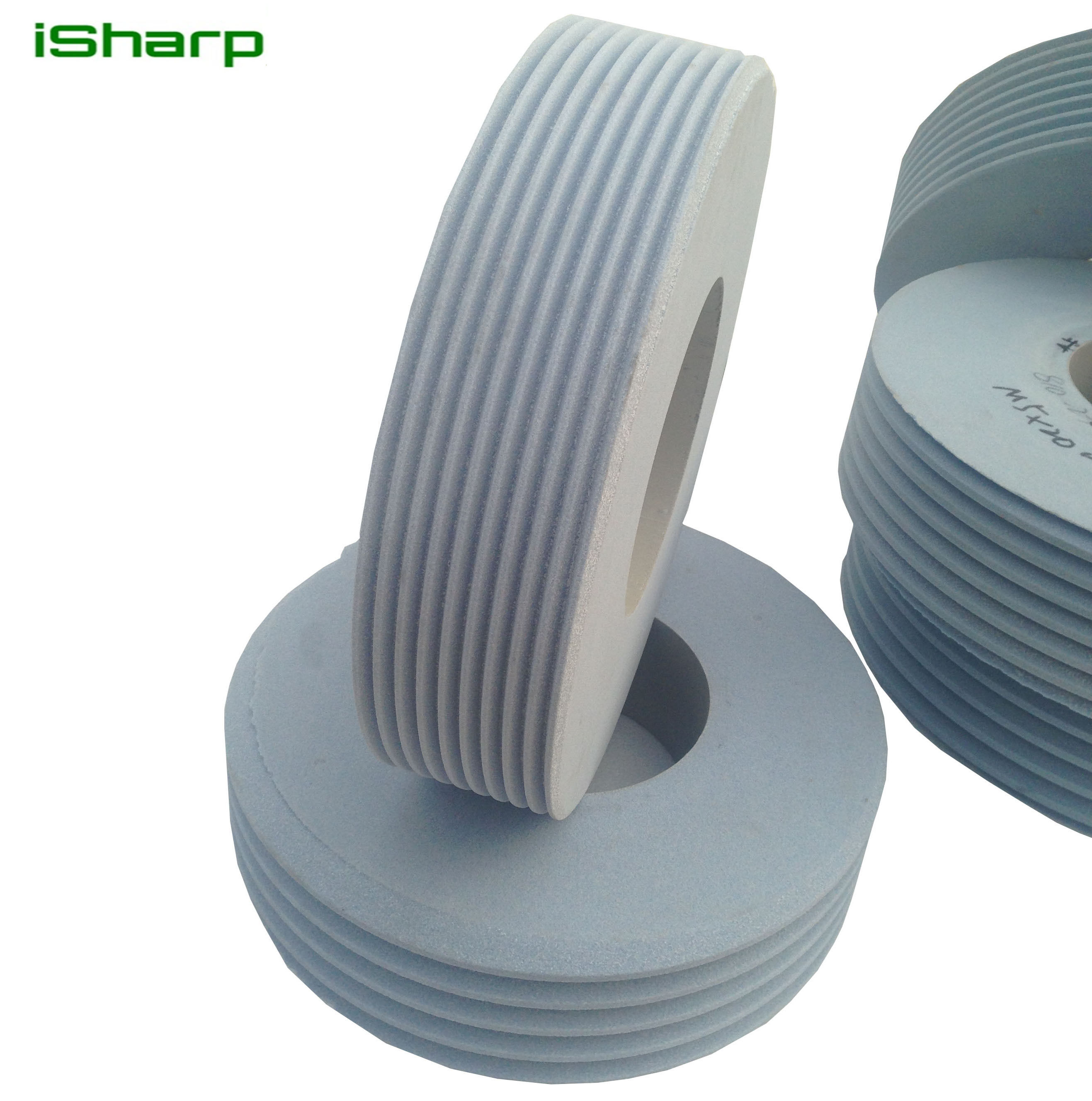

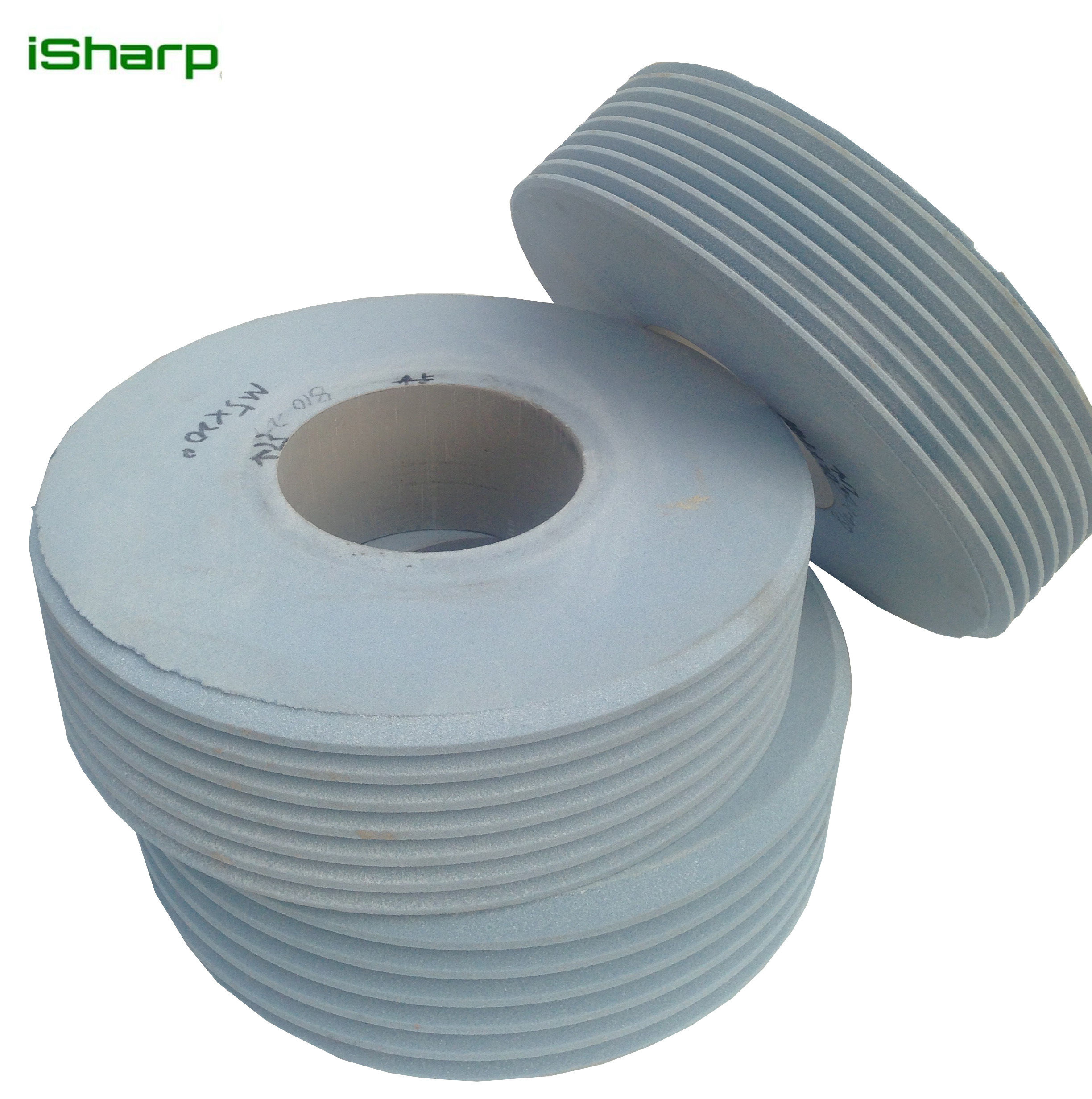

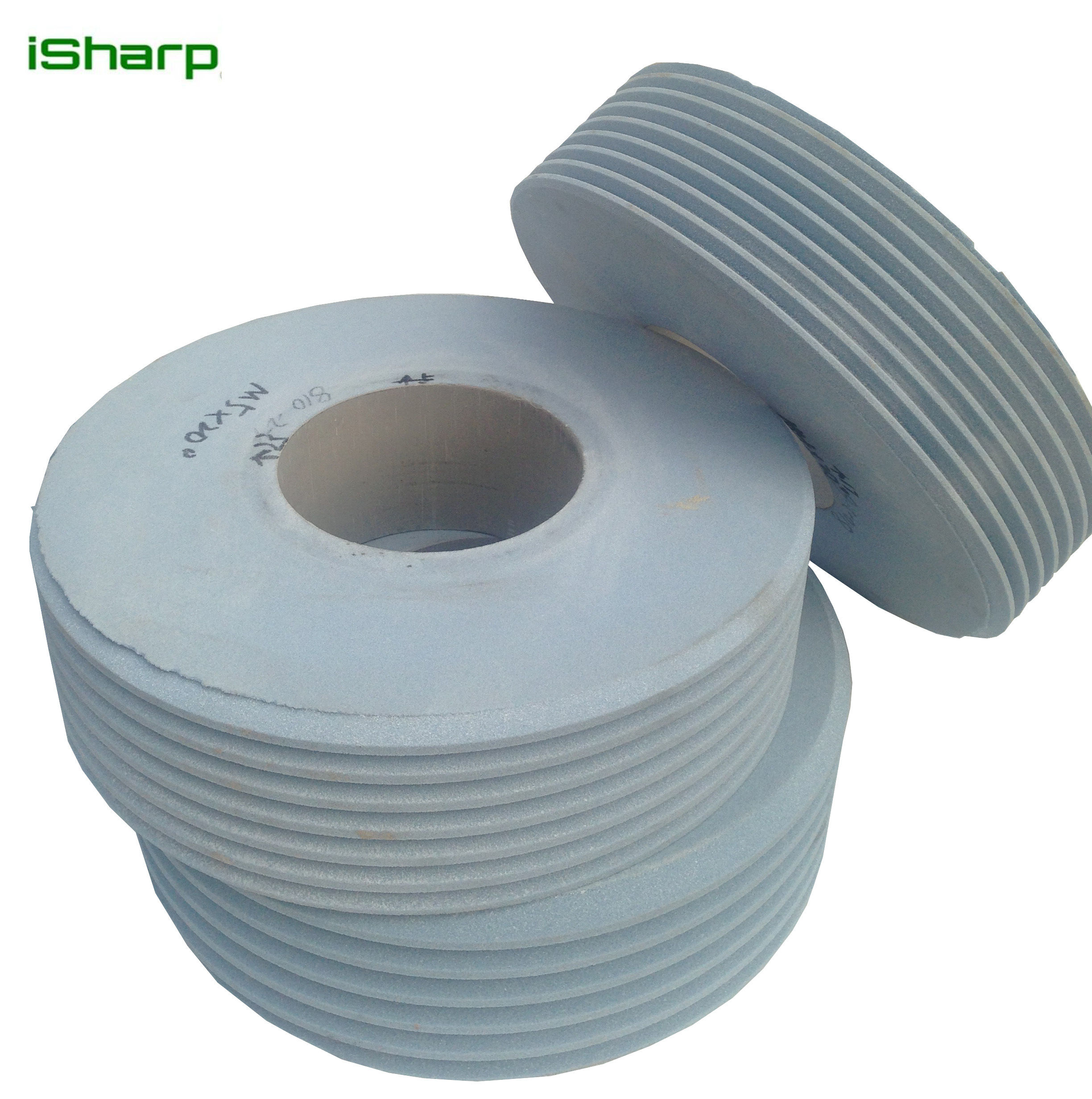

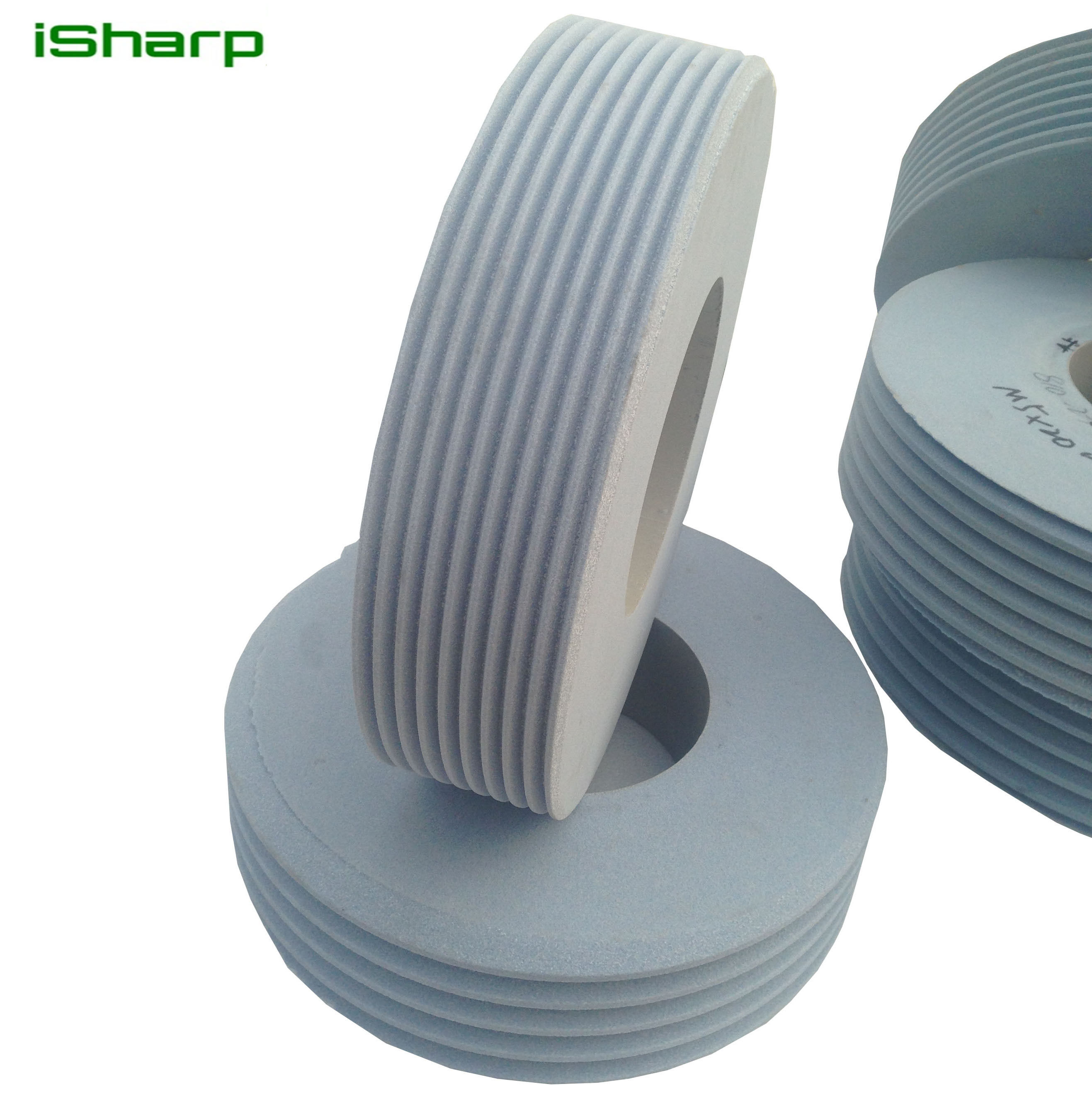

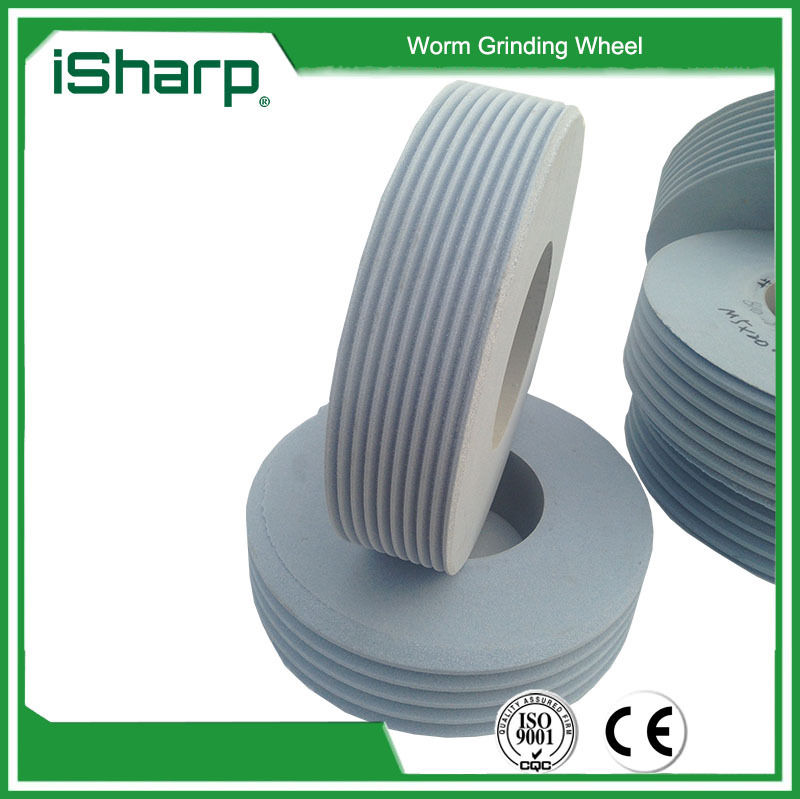

Worm Grinding Wheel for Continuous Gear Generation

Product Details:

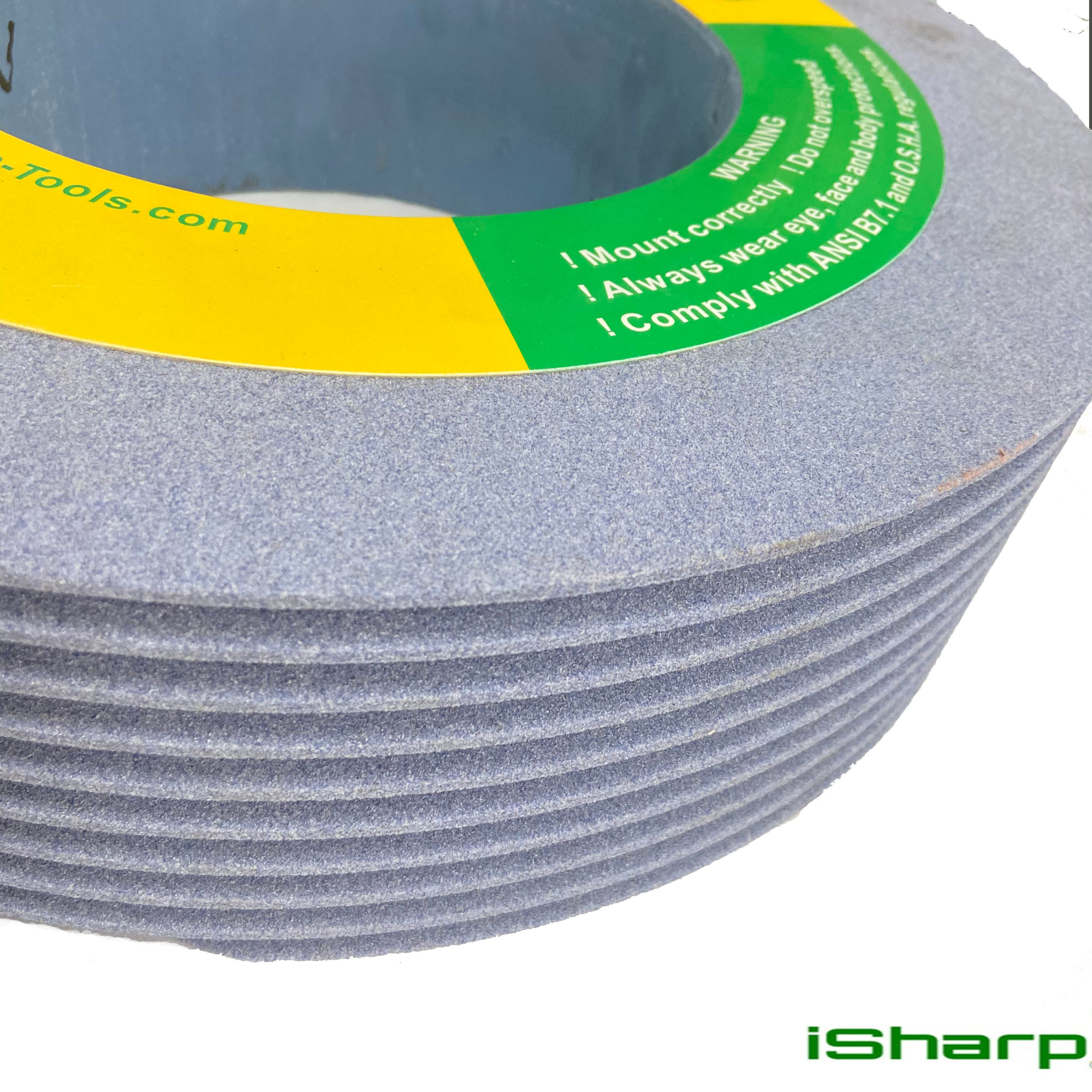

- Bonding Vitrified

- Toughness High Toughness for continuous duty

- Backing Reinforced core

- Grain Type Abrasive grain

- Hardness Medium to Hard

- Chemical Composition Al2O3 or Ceramic Matrix

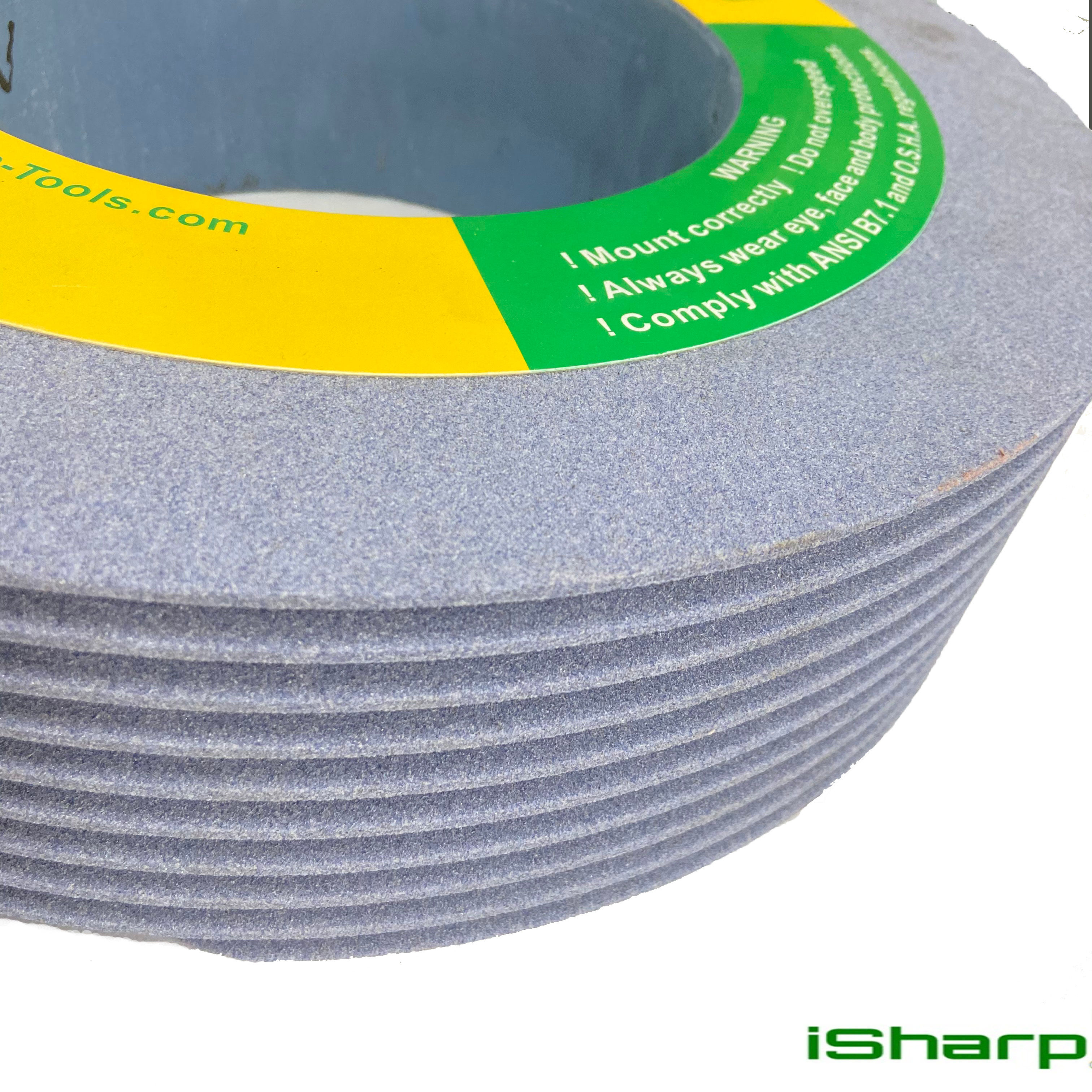

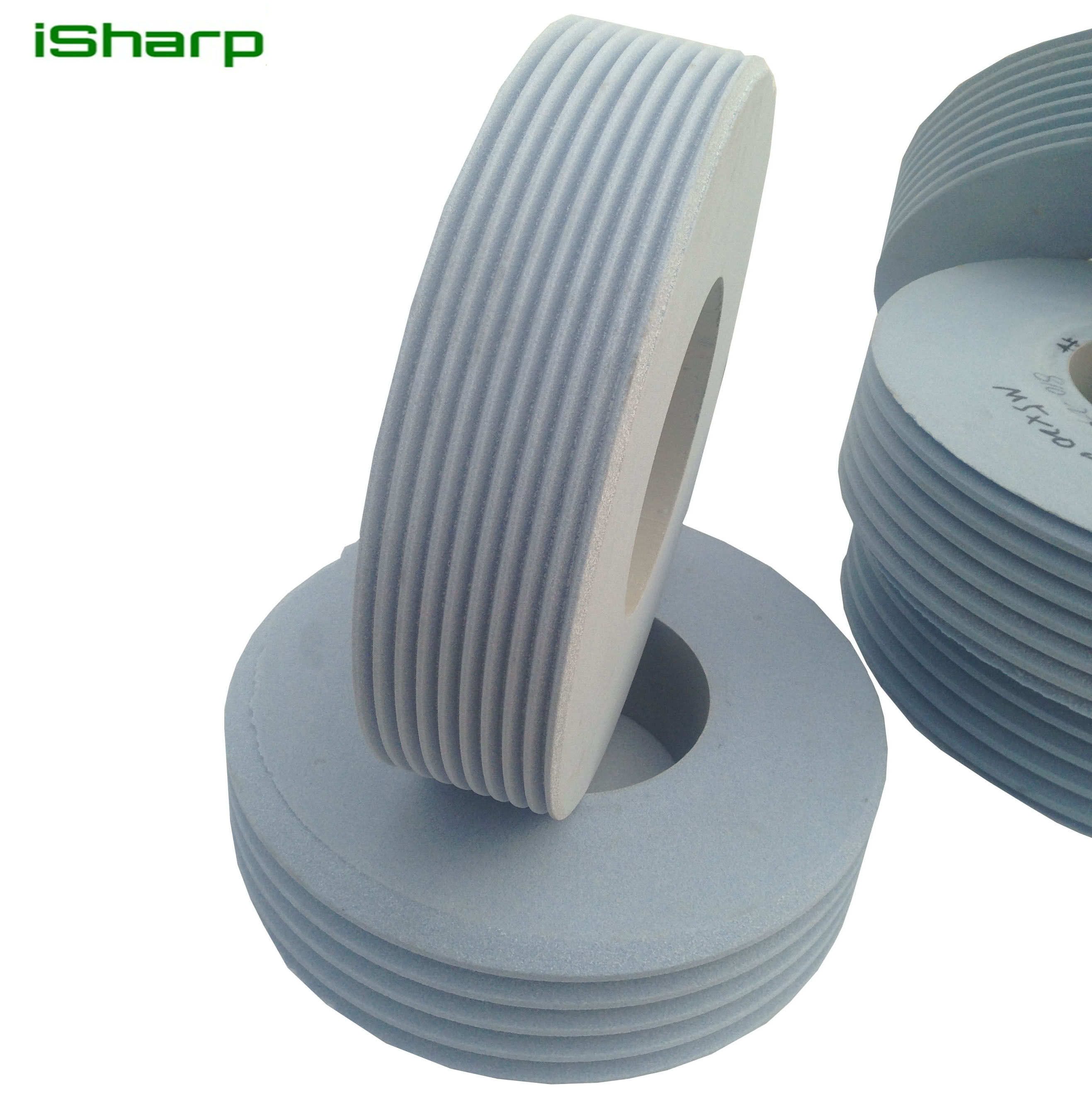

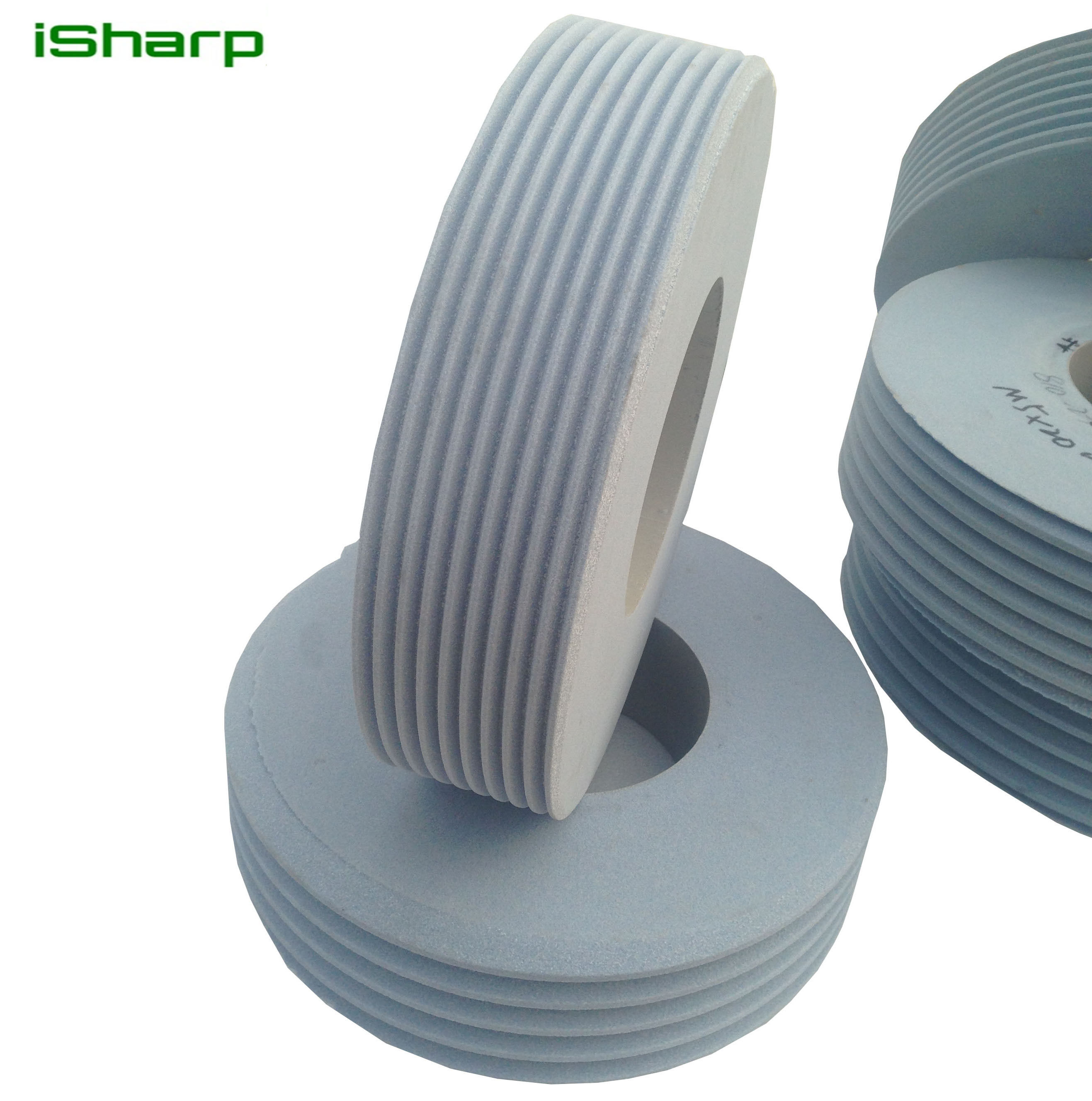

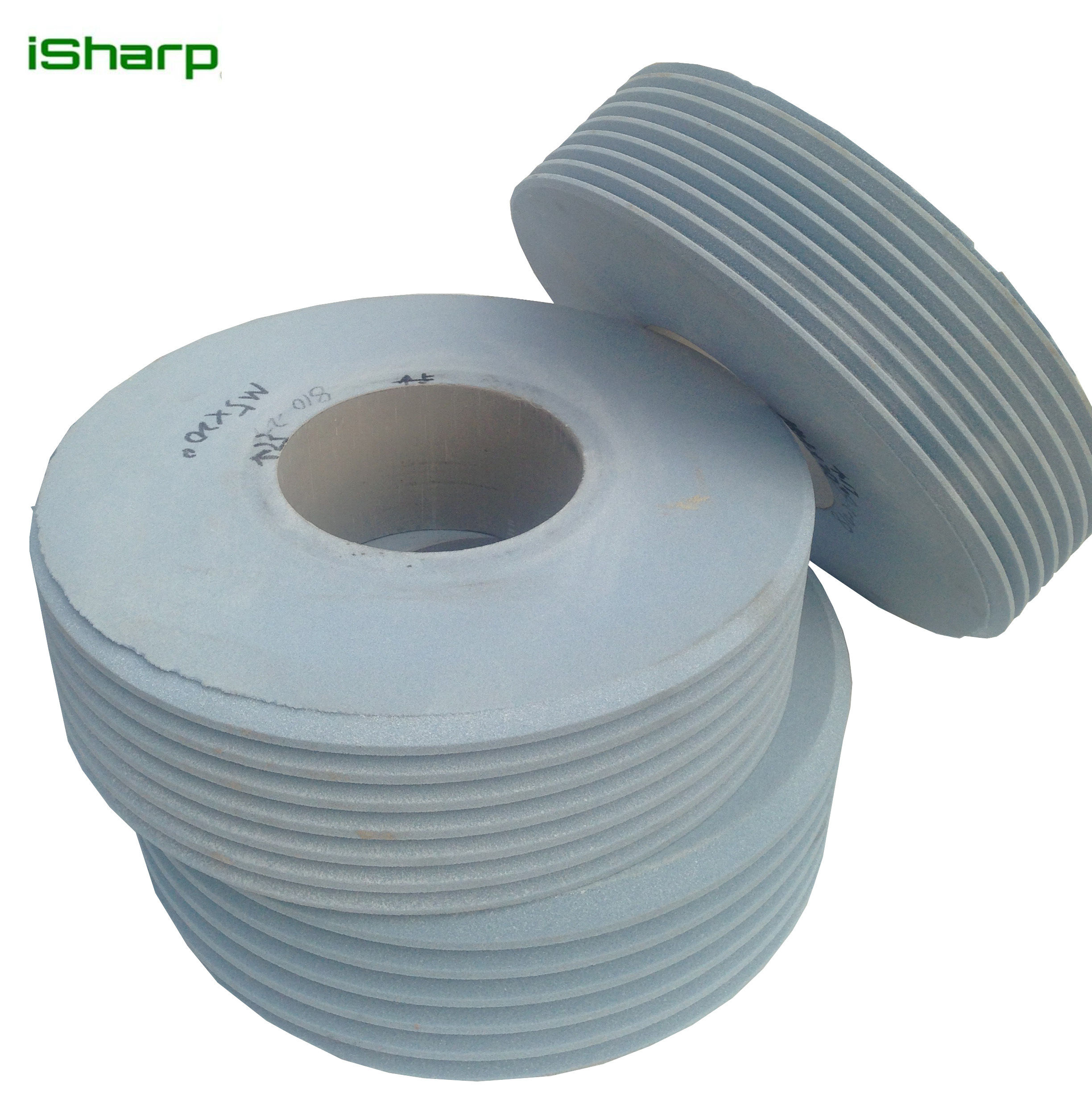

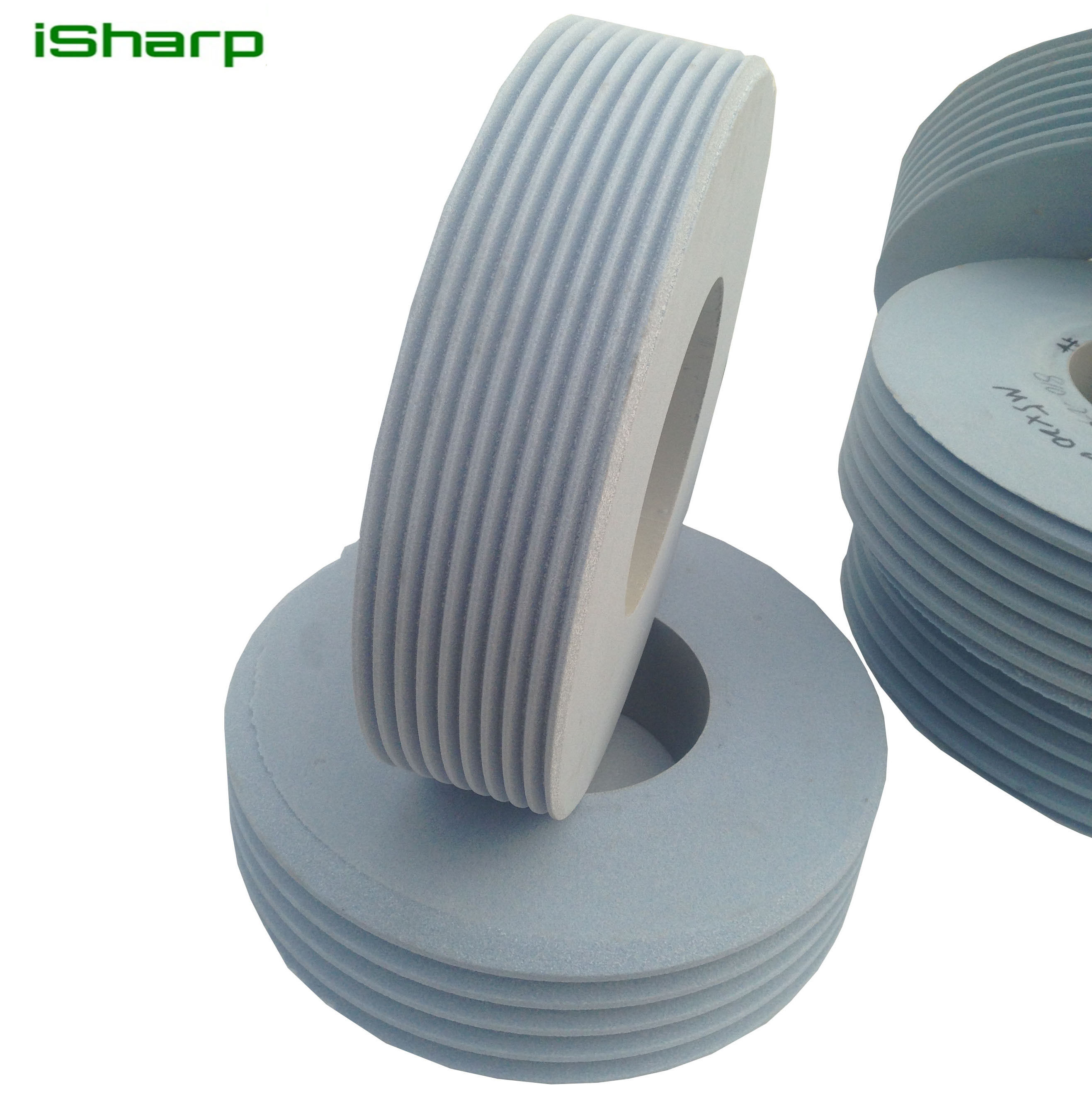

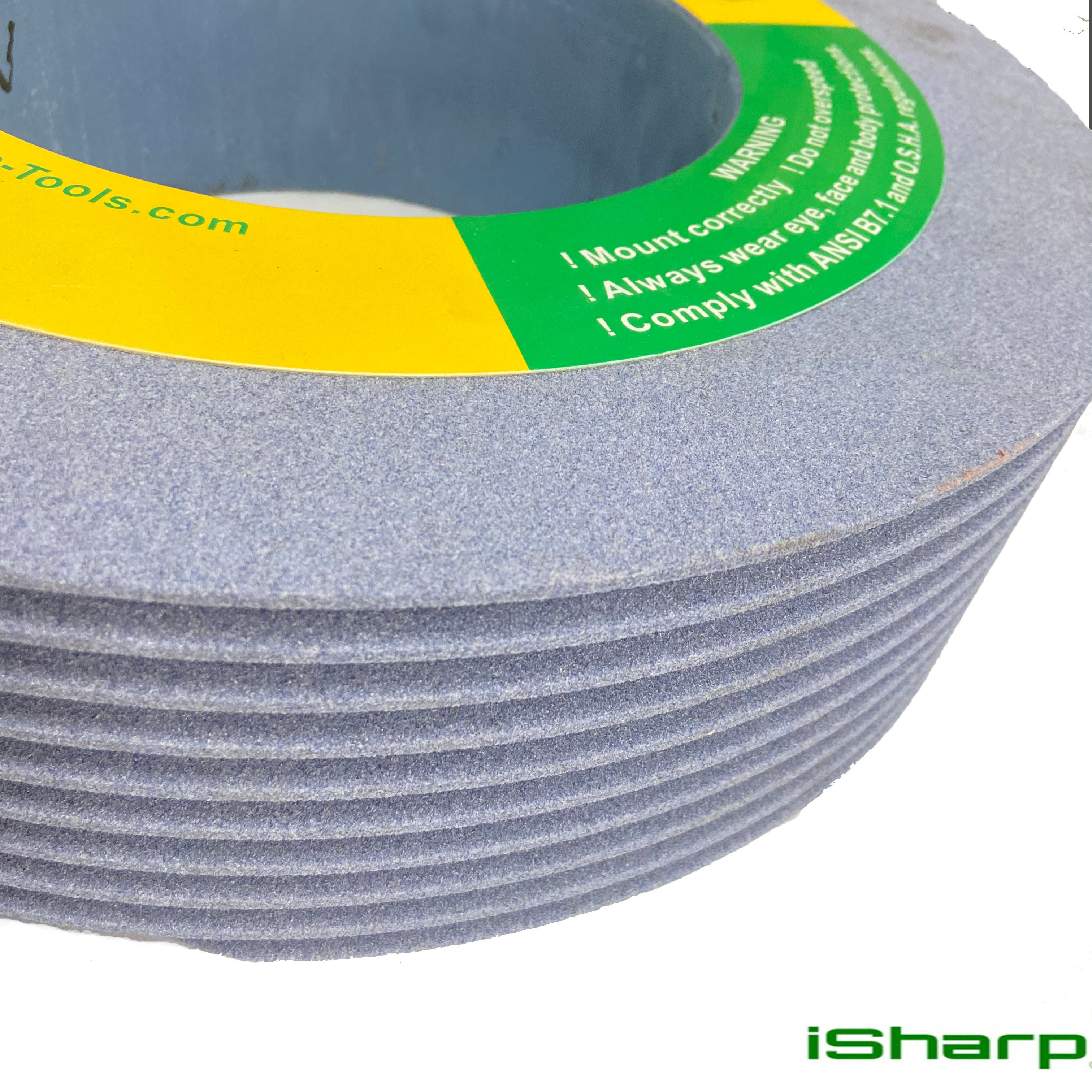

- Shape Worm profile

- Click to View more

Worm Grinding Wheel for Continuous Gear Generation Price And Quantity

- 50 USD ($)/Piece

- 10 Piece

- Suitable for oil or water-based coolants

- CNC and automatic gear grinding machines

- High dimensional accuracy and profile retention

- Up to Ra 0.4 m

- Continuous gear generation grinding

- Gray or off-white

- 10 mm to 200 mm

- Up to 80 m/s

- Extended tool life for production environments

Worm Grinding Wheel for Continuous Gear Generation Product Specifications

- High Toughness for continuous duty

- Vitrified

- Customizable as per requirements

- Abrasive grain

- Worm Grinding Wheel

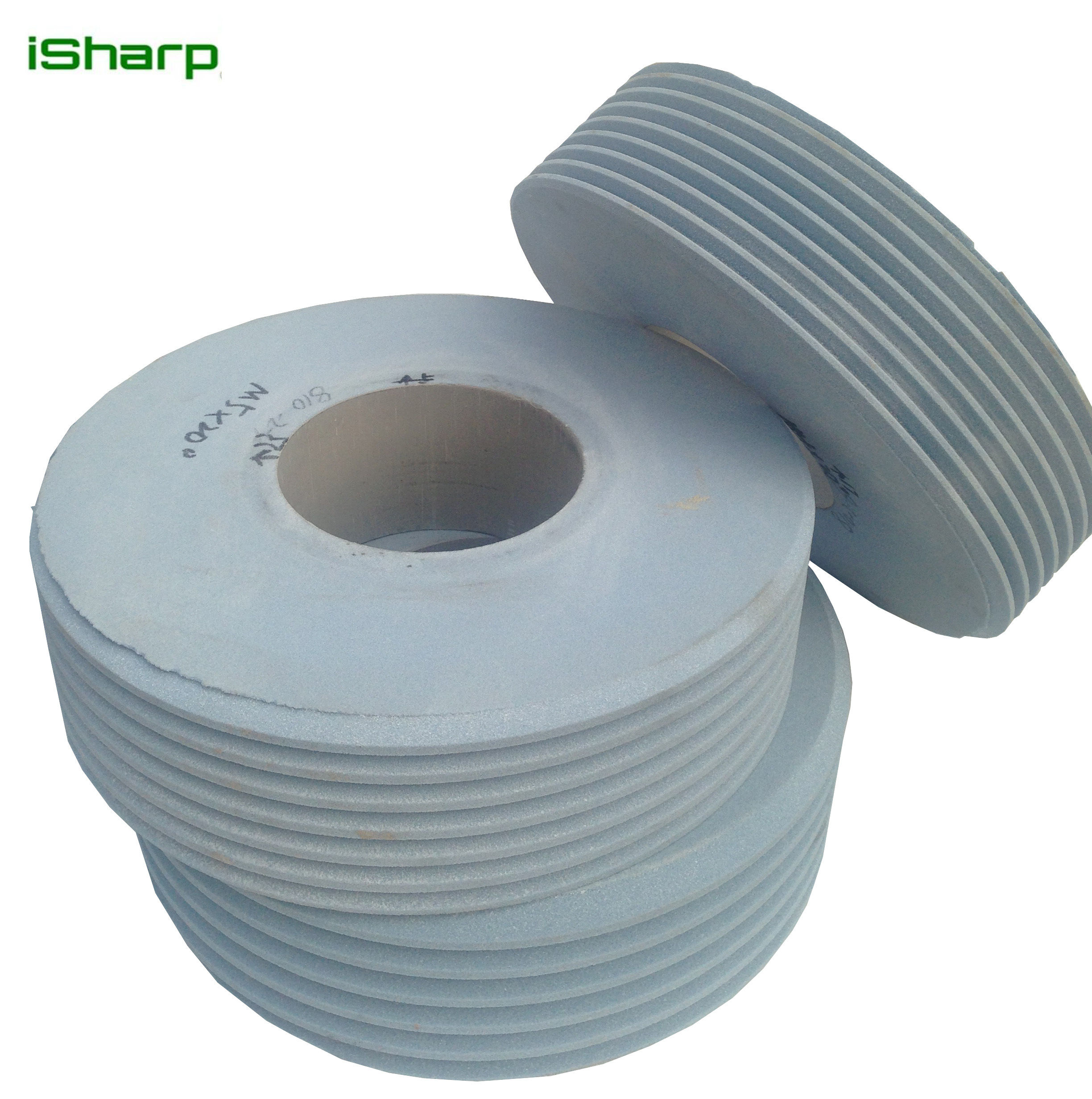

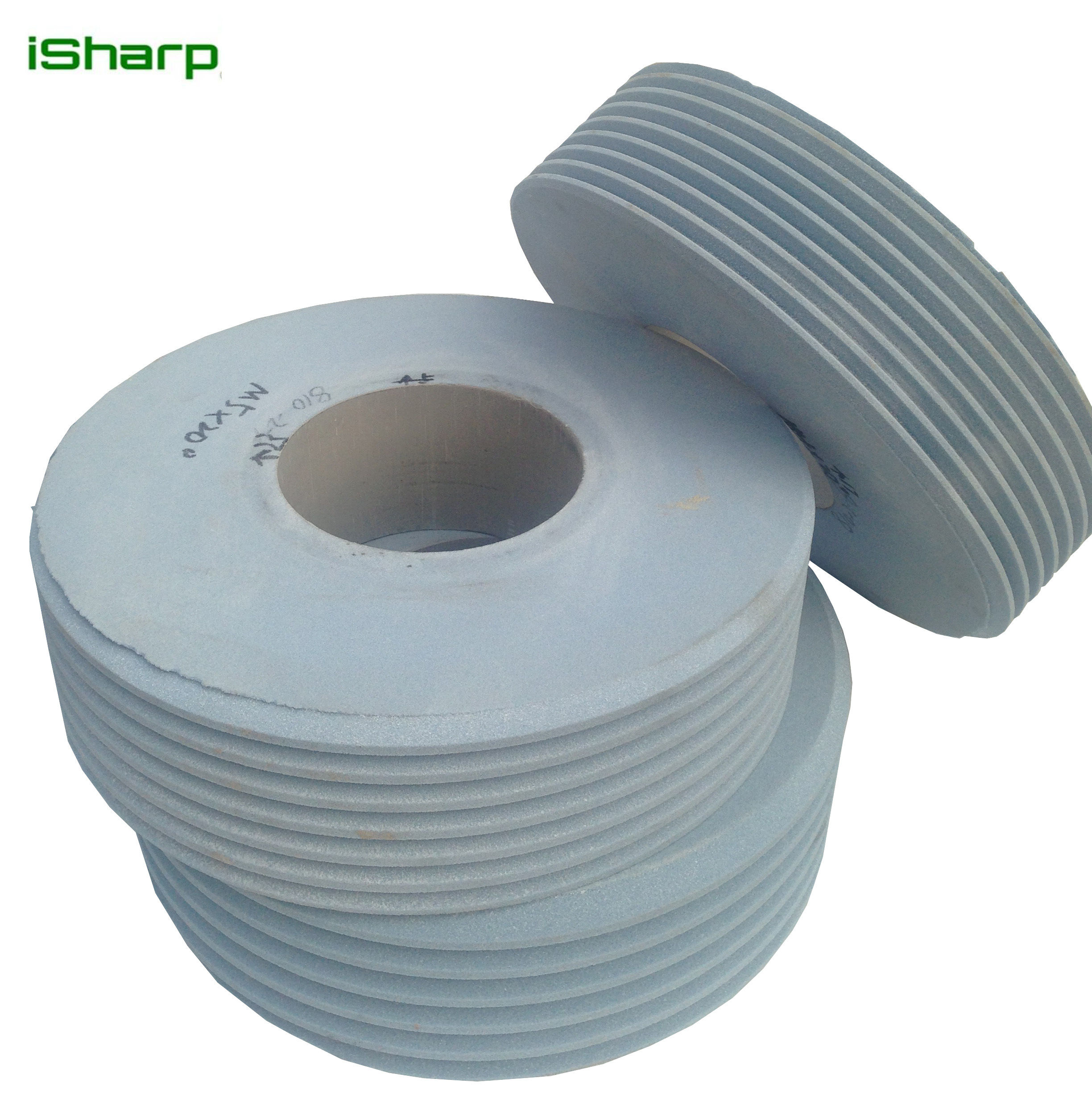

- Reinforced core

- Medium to Hard

- Al2O3 or Ceramic Matrix

- Aluminum Oxide or Ceramic Alumina

- Up to 350 mm in diameter

- F60 to F220

- Worm profile

- Suitable for oil or water-based coolants

- CNC and automatic gear grinding machines

- High dimensional accuracy and profile retention

- Up to Ra 0.4 m

- Continuous gear generation grinding

- Gray or off-white

- 10 mm to 200 mm

- Up to 80 m/s

- Extended tool life for production environments

Product Description

Product Descripation

This grinding wheel is made of premium oxide and efficient bond to sinter in low temperature. It can be applied in the grinding process of gear grinding machine like, Reishauer, Qinchuan, Gleason, KAPPA and so on.

Packaging

1) The gear grinding wheel are packed by cartons which suitable for long distance transportation.

2) The package can be customized according the customers requests.

Shipping & Delivery

1) Small samples shipping by express: DHL, FEDEX, THT...

2) Big order by sea (as per customers request)

FAQ

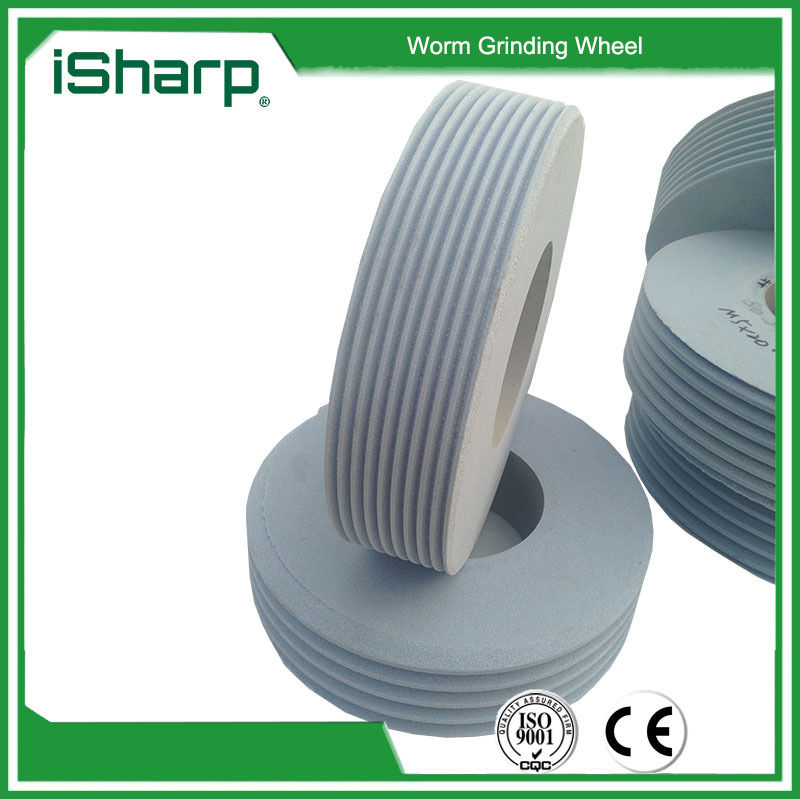

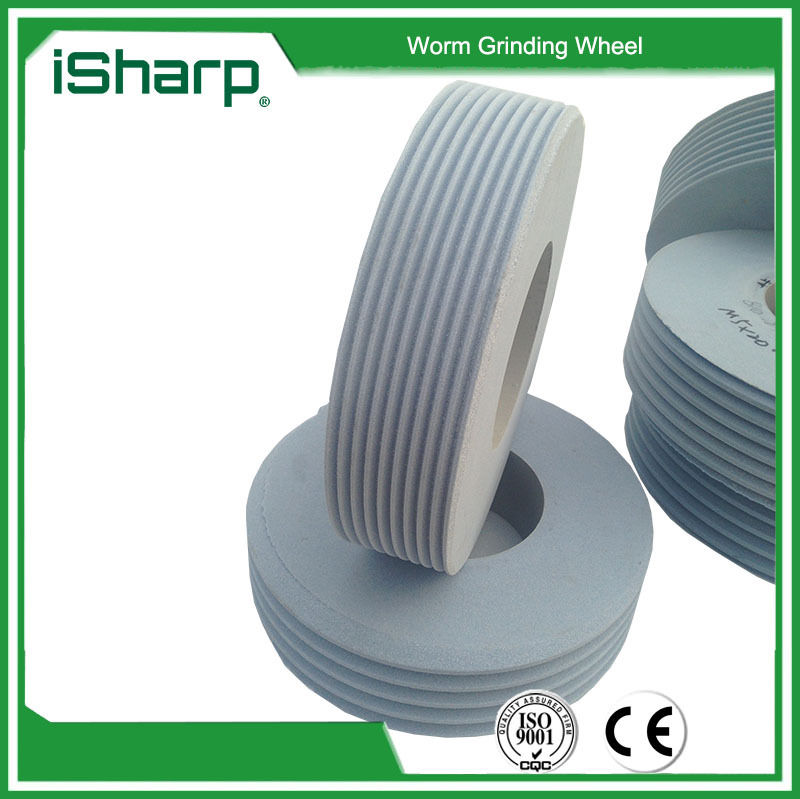

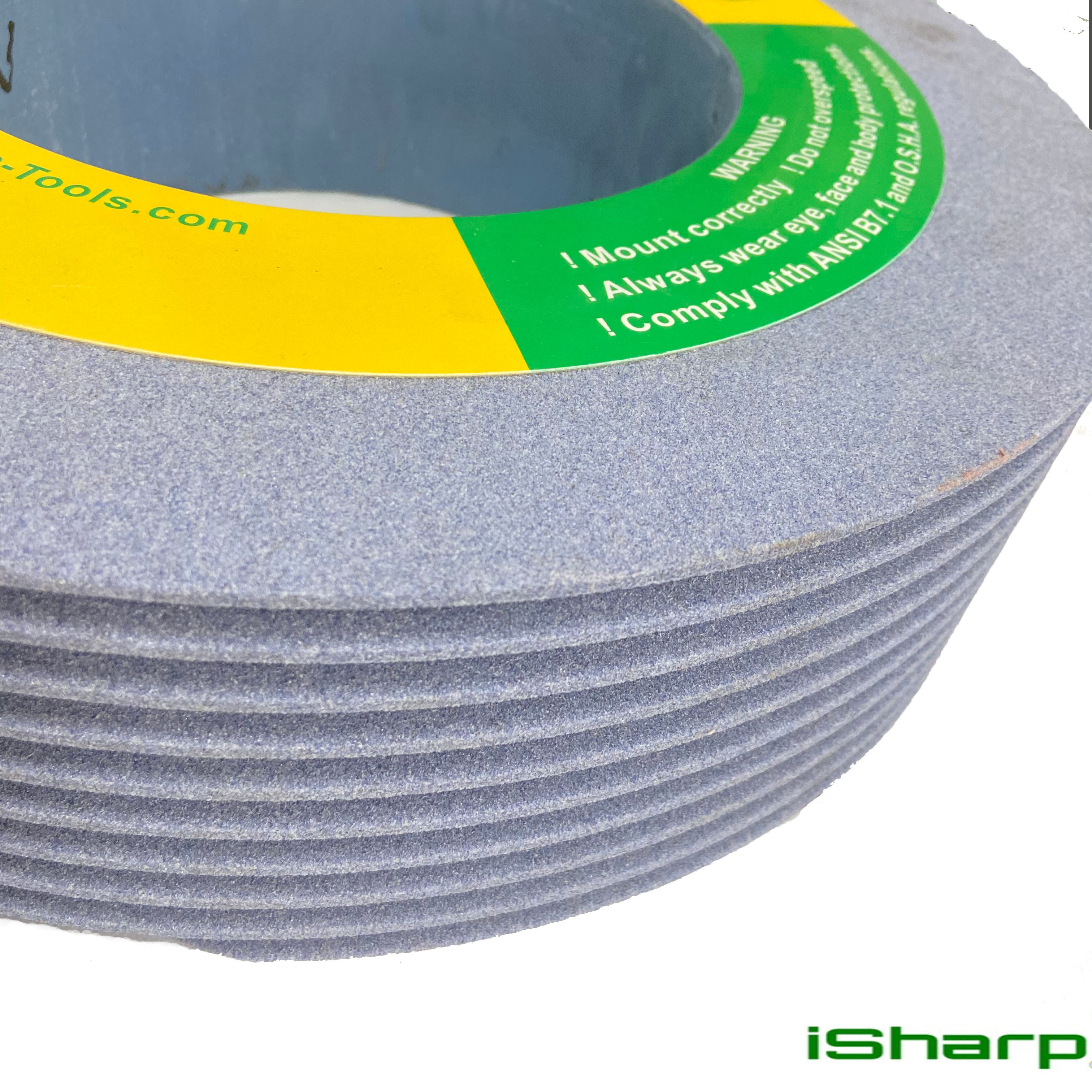

Q1: Does the grinding wheel has any safety certifications?

A1.Yes, we have ISO certifications.

Q2: What package do you use?

A2: Packing ways differ for different wheels. We offer normal carton packing and color box packing, all package will be suitable for long distance transportation.

Q3: Do you accept OEM order?

A3: Yes, OEM order is accepted. We can also help to design label for you.

Q4: How to ensure product quality?

A4: Raw materials selected strictly, control quality from the source. Each step has to pass the corresponding quality testing.

Precision Engineering for Gear Grinding

Our worm grinding wheel is meticulously crafted to deliver exceptional precision in gear generation. Utilizing advanced abrasive grains, the wheel guarantees high material removal rates while ensuring tight tolerances and minimal surface roughness, crucial for automated, high-volume gear manufacturing applications.

Adaptable for Modern Grinding Machines

Compatible with CNC and automatic gear grinding machines, this wheel integrates seamlessly into contemporary production lines. It is available in various widths and diameters, supporting a range of machine models and customer requirements. Its customizable strips and size make it a versatile choice for diverse gear profiles.

Optimal Performance and Extended Lifespan

Featuring a reinforced core and robust chemical composition, our worm grinding wheel offers high toughness, allowing for continuous operation with minimal wear. Its extended tool life makes it particularly well-suited to demanding production environments, helping to reduce downtime and improve overall productivity.

FAQ's of Worm Grinding Wheel for Continuous Gear Generation:

Q: How should the worm grinding wheel be maintained to ensure optimal performance?

A: To maintain optimal performance, regularly check for wheel wear, ensure proper dressing, and verify that the mounting is secure. Use recommended coolant-oil or water-based-during operation to prevent overheating and maintain surface integrity.Q: What are the benefits of using this grinding wheel for continuous gear generation?

A: This worm grinding wheel offers high dimensional accuracy, superior surface finish (up to Ra 0.4 m), and exceptional profile retention, making it perfect for continuous gear generation in high-production setups with minimal downtime.Q: When is it necessary to replace the grinding wheel?

A: Replace the wheel when there is visible wear, reduced grinding performance, or when it no longer achieves the required surface finish or gear profile tolerances. Regularly monitoring these factors will extend tooling life and maintain part quality.Q: Where can this grinding wheel be used?

A: The worm grinding wheel is suitable for CNC and automatic gear grinding machines in industries such as automotive, aerospace, and industrial machinery. Its versatility allows it to be used in both large-scale manufacturing plants and specialized gear shops.Q: What is the recommended process for mounting the grinding wheel?

A: Before installation, inspect the wheel for damage. Mount it on a clean, compatible spindle using the manufacturer's recommended torque. Ensure the wheel is properly balanced and aligned prior to use to avoid vibration and maintain precision.Q: How does the chemical composition contribute to the wheel's performance?

A: The wheel's Al2O3 or ceramic matrix composition, combined with a vitrified bond, imparts high toughness, thermal stability, and consistent abrasive action, which is crucial for continuous duty and reliable gear grinding outcomes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+