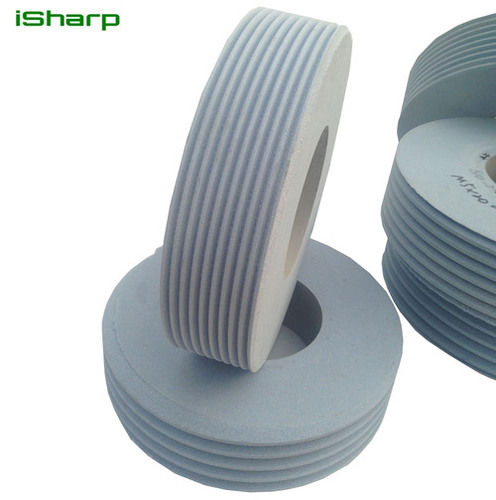

Isharp Cylindrical Gear Profile Grinding Wheel with high quality

Product Details:

- Grain Type Aluminum Oxide or CBN

- Toughness High fracture toughness for endurance in gear grinding

- Shape Profiled and cylindrical

- Chemical Composition Primarily AlO for aluminum oxide wheels or cubic boron nitride (CBN)

- Backing Strong fiber or reinforced composite backing

- Bonding Resinoid or Vitrified Bond

- Hardness Medium to High (coded from H to R depending on application)

- Click to View more

Isharp Cylindrical Gear Profile Grinding Wheel with high quality Price And Quantity

- 50 USD ($)/Piece

- 50.00 - 200.00 USD ($)/Piece

- 500 Piece

Isharp Cylindrical Gear Profile Grinding Wheel with high quality Product Specifications

- As per customer requirement, commonly available from 150 mm to 500 mm diameter

- Medium to High (coded from H to R depending on application)

- Customized as per gear grinder specifications

- Available in grit sizes from 46 to 220

- Resinoid or Vitrified Bond

- Primarily AlO for aluminum oxide wheels or cubic boron nitride (CBN)

- Strong fiber or reinforced composite backing

- High purity grinding abrasive

- Cylindrical Gear Profile Grinding Wheel

- Profiled and cylindrical

- High fracture toughness for endurance in gear grinding

- Aluminum Oxide or CBN

Product Description

Using nanometer gathering crystal corundum,high strong and efficiency bond.Adopting unique easel design makes the grinding wheel to be characterized by high efficiency cutting,low heating value,high durability and good shape holding.It makes the grinding wheel with all excellent indexes and performance price ratio.

Widely used in CNC grinding machine such as Niels,Hoffler,Pfauter,Sumptasli,Qinchuan,etc.

When ordering,parameters such as gear modulus and pressure angle must be provided.

FAQ

Q1: Does the grinding wheel has any safety certifications?

A1.Yes, we have ISO certifications.

Q2: What package do you use?

A2: Packing ways differ for different wheels. We offer normal carton packing and color box packing, all package will be suitable for long distance transportation.

Q3: Do you accept OEM order?

A3: Yes, OEM order is accepted. We can also help to design label for you.

Q4: How to ensure product quality?

A4: Raw materials selected strictly, control quality from the source. Each step has to pass the corresponding quality testing.

Precision Engineering for Gear Manufacturing

Isharp Cylindrical Gear Profile Grinding Wheels are designed for demanding automotive and industrial applications. Their ISO and CE-compliant construction ensures reliability, while dynamic balancing and specialized composition enable precise, vibration-free operation. Available in profiled or cylindrical shapes, these wheels consistently deliver high-quality surface finishes required in gear manufacturing processes.

Versatile Customization to Suit Your Needs

With options in wheel diameter, thickness, grain size, and backing reinforcement, these grinding wheels are tailored for a wide variety of machines and gear grinder specifications. Whether you require aluminum oxide or CBN abrasive, or specific strip and roll sizes, Isharp offers solutions that optimize grinding according to your gear manufacturing requirements.

Durability and Efficiency in Every Operation

Designed for longevity and consistent performance, the wheels feature open structures for effective coolant flow and chip release. Their compatibility with both water and oil-based coolants boosts thermal regulation during operation, reducing wear and ensuring uniform grinding quality for extended production runs.

FAQ's of Isharp Cylindrical Gear Profile Grinding Wheel with high quality:

Q: How do Isharp Cylindrical Gear Profile Grinding Wheels improve the gear grinding process?

A: These wheels provide controlled porosity and high fracture toughness, allowing efficient coolant supply, superior chip removal, and reduced vibration. This results in high-precision gear surface finishes and longer tool life.Q: What are the main applications for these grinding wheels?

A: Isharp Cylindrical Gear Profile Grinding Wheels are primarily designed for fine and profile grinding of cylindrical gear flank surfaces, commonly used in automotive and industrial gear production.Q: When should I choose aluminum oxide versus CBN grain types?

A: Aluminum oxide is suitable for most steel gear grinding applications due to its versatility and cost-efficiency. CBN (Cubic Boron Nitride) is recommended for hard or heat-sensitive materials, offering extended durability and precision under high loads.Q: Where are these grinding wheels typically utilized?

A: They are widely used in gear manufacturing plants, including automotive and industrial machinery sectors where high-quality, precision-ground gears are essential for product performance.Q: What is the process for customizing the wheel size and specifications?

A: Customers can specify required roll diameters (150-500 mm), thicknesses (10-80 mm), grit size (46-220), and strip dimensions to match their grinding machinery and production needs. Isharp manufactures wheels to these specifications for optimal compatibility and performance.Q: How does dynamic balancing benefit grinding wheel performance?

A: Dynamic balancing minimizes vibration during grinding, improving surface finish quality, extending machine lifespan, and reducing operator fatigue, making the process smoother and more efficient.Q: What are the advantages of using resinoid or vitrified bonds in these wheels?

A: Resinoid bonds offer flexibility and resilience suited for high-speed operations, while vitrified bonds provide strength and stability for consistent performance, allowing customers to select the best bond for their application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese