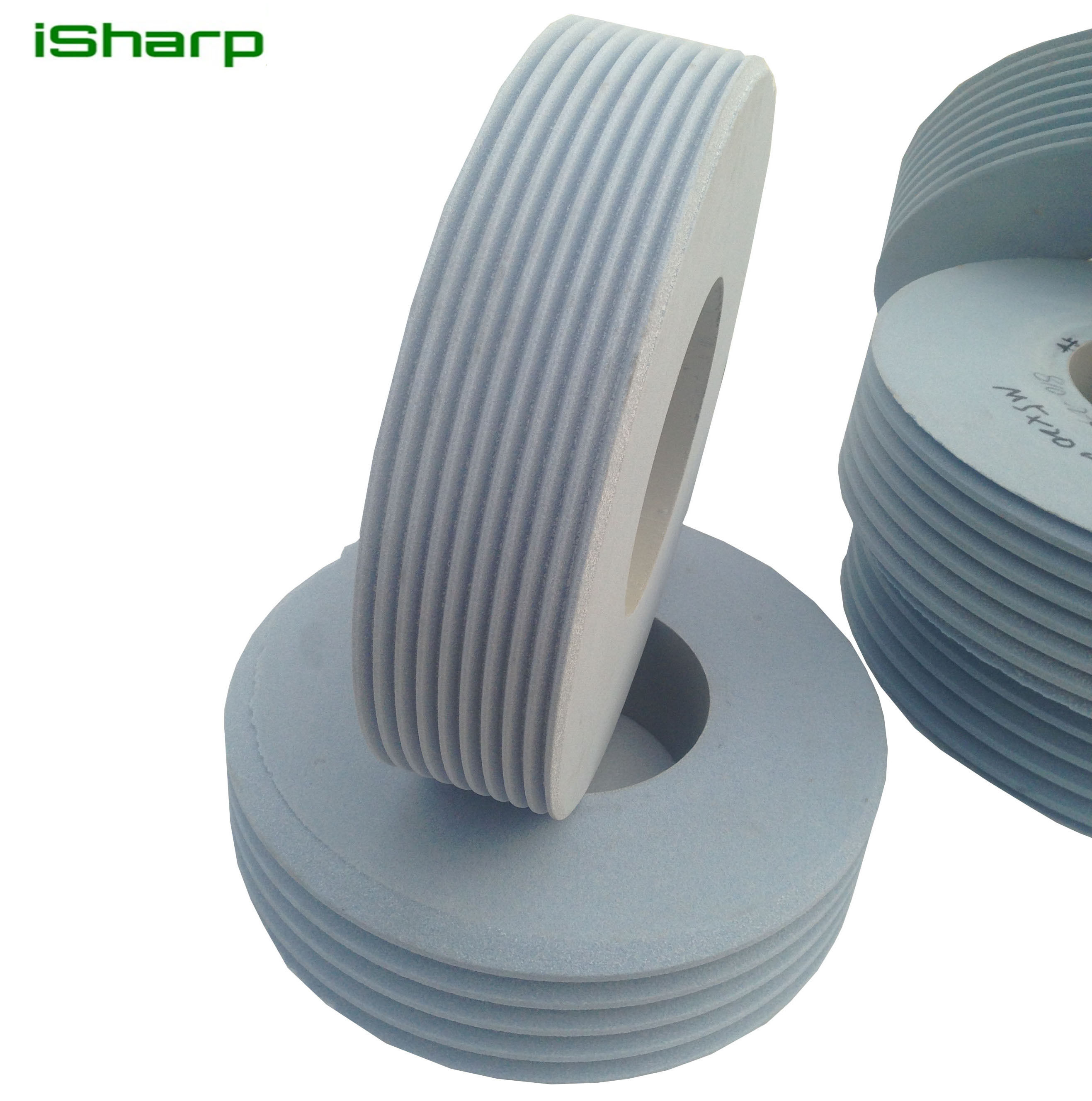

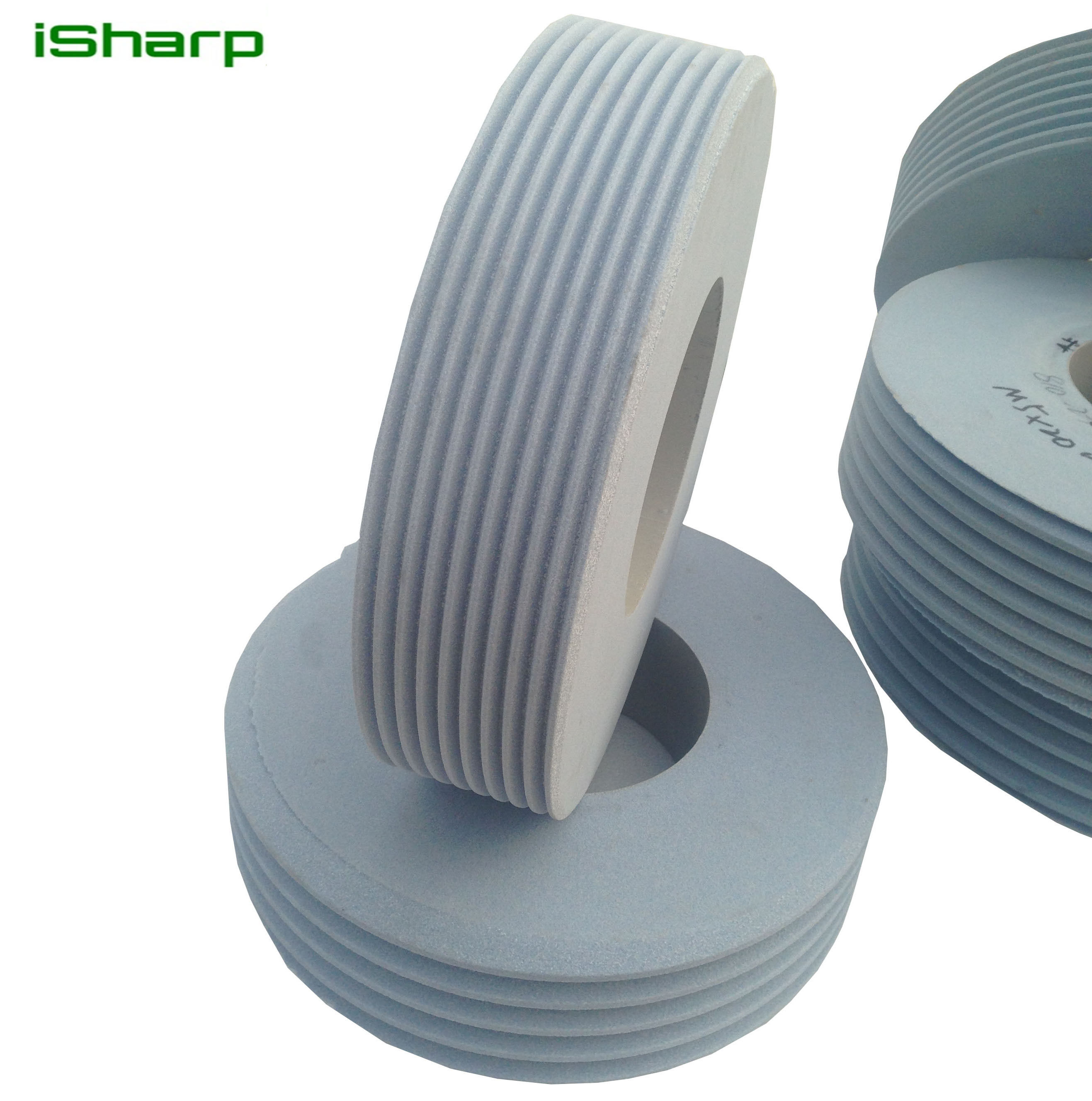

Common Worm Gear Grinding Wheel

50 USD ($)/Piece

Product Details:

- Hardness Medium to Hard (K-N as per application)

- Chemical Composition Specific to abrasive selection; can include Al2O3, CBN, or Diamond with bonding agents

- Grain Type Mono-crystalline/Polycrystalline

- Backing Wheel core of steel or composite alloy

- Shape Profiled (Worm type)

- Toughness High (suitable for precision gear grinding)

- Bonding Vitrified or Resin bond

- Click to View more

X

Common Worm Gear Grinding Wheel Price And Quantity

- 500 Piece

- 50 USD ($)/Piece

- Gray/Brown (depends on material)

- Fits standard CNC gear grinding machines

- Wet or dry use (recommended wet for high-performance grinding)

- 35-50 m/s (depending on diameter and bonding type)

- Precision grinding of hardened gear teeth

- Ra 0.2-0.5 m

- Pre-balanced for high-speed operation

Common Worm Gear Grinding Wheel Product Specifications

- Mono-crystalline/Polycrystalline

- Wheel core of steel or composite alloy

- Profiled (Worm type)

- High (suitable for precision gear grinding)

- Vitrified or Resin bond

- 46-180 grit (customizable)

- Custom as per application (commonly 300-400 mm diameter)

- Abrasive (Aluminium Oxide, CBN, or Diamond based on application)

- As specified by the gear size and grinding machine

- Medium to Hard (K-N as per application)

- Specific to abrasive selection; can include Al2O3, CBN, or Diamond with bonding agents

- Worm Gear Grinding Wheel

- Gray/Brown (depends on material)

- Fits standard CNC gear grinding machines

- Wet or dry use (recommended wet for high-performance grinding)

- 35-50 m/s (depending on diameter and bonding type)

- Precision grinding of hardened gear teeth

- Ra 0.2-0.5 m

- Pre-balanced for high-speed operation

Product Description

1. Packaging1) The gear grinding wheel are packed by cartons which suitable for long distance transportation.

2) The package can be customized according the customers requests.

2. Shipping & Delivery

1) Small samples shipping by express: DHL, FEDEX, THT...

2) Big order by sea (as per customers request)

FAQ

Q1: Does the grinding wheel has any safety certifications?

A1.Yes, we have ISO certifications.

Q2: What package do you use?

A2: Packing ways differ for different wheels. We offer normal carton packing and color box packing, all package will be suitable for long distance transportation.

Q3: Do you accept OEM order?

A3: Yes, OEM order is accepted. We can also help to design label for you.

Q4: How to ensure product quality?

A4: Raw materials selected strictly, control quality from the source. Each step has to pass the corresponding quality testing.

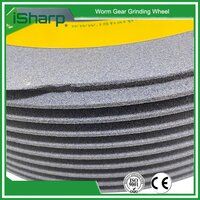

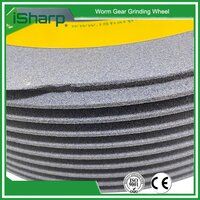

High-Performance Gear Tooth Grinding

This worm gear grinding wheel is designed for finishing hardened gear teeth in high-precision applications. Its abrasive composition, featuring Aluminium Oxide, CBN, or Diamond, ensures outstanding toughness, making it ideal for demanding manufacturing environments where accuracy and durability are vital.

Customizable to Your Precise Needs

Available in various diameters (commonly 300-400 mm) and grain sizes (46-180 grit), this grinding wheel can be customized to fit the dimensions of your gear teeth and the requirements of your CNC gear grinding machine. Its compatibility with different bonding types and backing materials offers increased versatility.

Optimized for Performance and Safety

Each wheel is pre-balanced for stable high-speed grinding, supporting maximum operating speeds of 35-50 m/s. The option for either wet or dry use-though wet is recommended-ensures the best grinding performance while minimizing thermal damage and extending tool life.

FAQ's of Common Worm Gear Grinding Wheel:

Q: How is the common worm gear grinding wheel used in gear manufacturing?

A: This grinding wheel is employed in the finishing stage of gear manufacturing for precision grinding of hardened gear teeth, providing a fine surface finish and precise tooth geometry essential for optimal gear operation.Q: What benefits does this grinding wheel offer compared to standard wheels?

A: It achieves very low surface roughness (Ra 0.2-0.5 m), supports high-speed operation, and is made with high-toughness abrasives like Aluminium Oxide, CBN, or Diamond for longer life and superior performance in demanding settings.Q: When should wet grinding be used instead of dry grinding?

A: Wet grinding is recommended for high-performance applications where controlling heat generation, ensuring optimal surface finish, and prolonging wheel life are critical. Dry grinding may be used for less demanding or rapid stock removal operations.Q: Where can this grinding wheel be used?

A: It is compatible with standard CNC gear grinding machines found in automotive, industrial gear manufacturing, and related sectors, making its use widespread across industries that require precise hardened gear production.Q: What is the process for selecting the right wheel specification?

A: Wheel selection is based on gear size, hardness, desired surface finish, and machine capability. Factors include diameter (usually 300-400 mm), abrasive type, grit size, bonding, strip dimensions, and compatibility with specific CNC machines.Q: How does pre-balancing improve wheel safety and performance?

A: Pre-balanced wheels ensure smooth, vibration-free operation at high speeds (up to 50 m/s), minimizing machine wear and producing more consistent, accurate gear grinding outcomes.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email