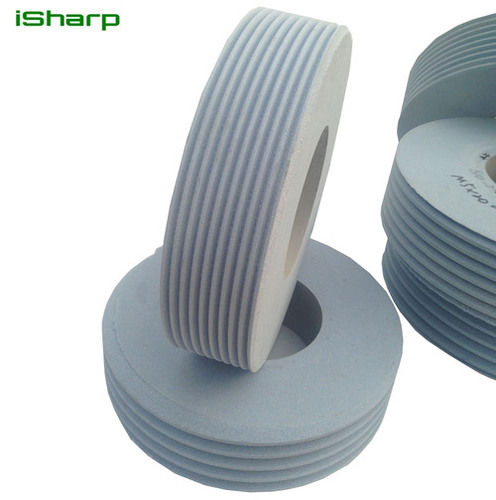

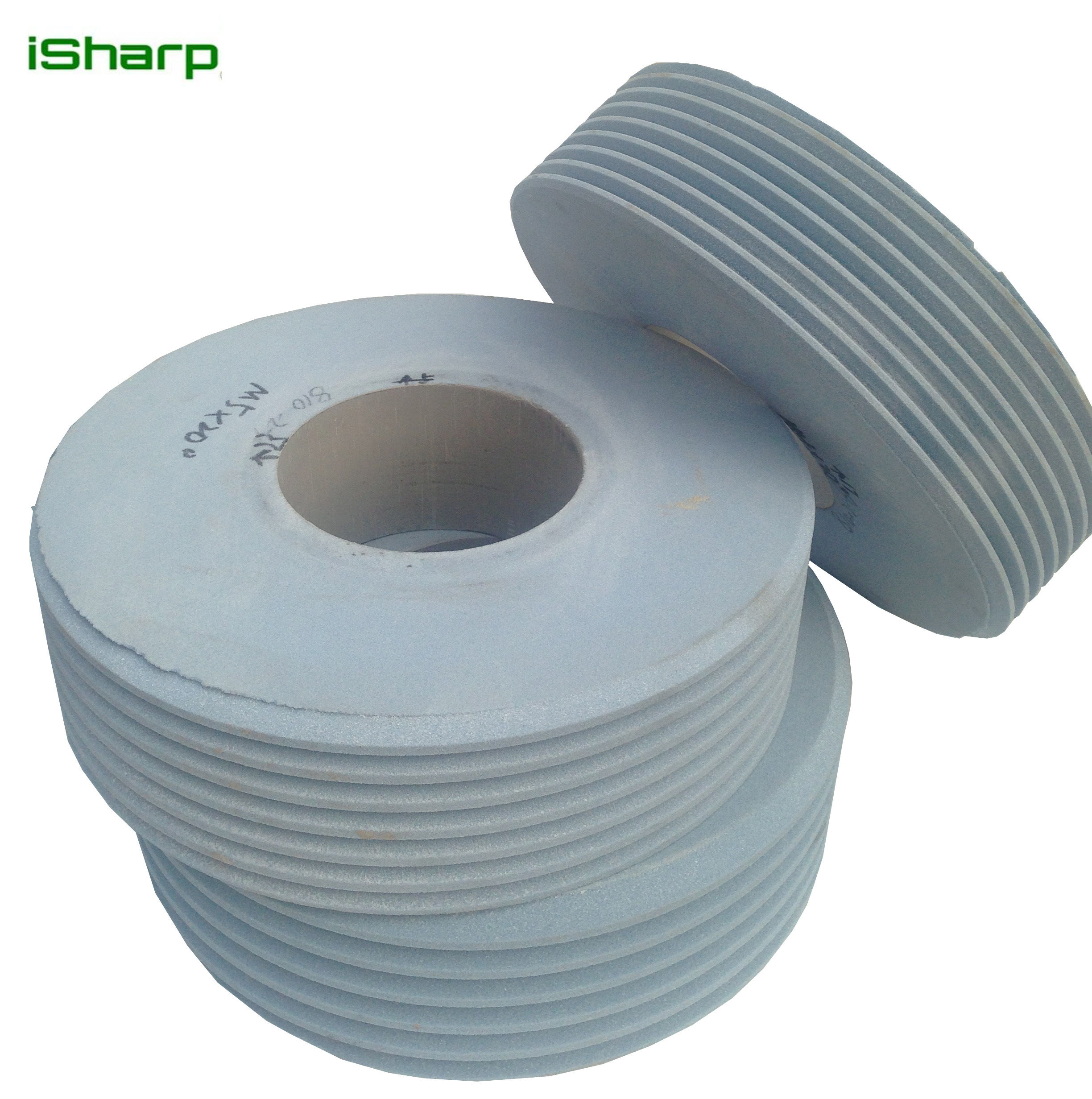

High Quality Abrasive Grinding Wheel for Gear Vitrified Grinding Wheel

50 USD ($)/Piece

Product Details:

- Hardness Medium to Hard (N R)

- Chemical Composition Al2O3, SiC, Ceramic, possible inclusion of CBN

- Shape Disk / Ring / Plate (custom shapes available)

- Bonding Vitrified (Ceramic)

- Backing Reinforced core

- Grain Type Agglomerate/Grit

- Toughness High

- Click to View more

X

High Quality Abrasive Grinding Wheel for Gear Vitrified Grinding Wheel Price And Quantity

- 200 Piece

- 50 USD ($)/Piece

- Grey / Blue / White

- Excellent

- 50 mm 450 mm

- Up to 80 m/s

- Extendedsuitable for high production volumes

- High precision, Ra 0.2 m

- CNC and Manual Gear Grinding Machines

- OEM/ODM supported

- Optimized for controlled coolant flow

- 0.01 mm

- Gear profile grinding, gear finishing operations

High Quality Abrasive Grinding Wheel for Gear Vitrified Grinding Wheel Product Specifications

- Disk / Ring / Plate (custom shapes available)

- Al2O3, SiC, Ceramic, possible inclusion of CBN

- Vitrified Grinding Wheel

- Aluminum Oxide / Ceramic / CBN

- Customizable as per gear dimensions

- Medium to Hard (N R)

- 4 inch, 6 inch, 8 inch or as required

- Reinforced core

- High

- Agglomerate/Grit

- Vitrified (Ceramic)

- 46# 220#

- Grey / Blue / White

- Excellent

- 50 mm 450 mm

- Up to 80 m/s

- Extendedsuitable for high production volumes

- High precision, Ra 0.2 m

- CNC and Manual Gear Grinding Machines

- OEM/ODM supported

- Optimized for controlled coolant flow

- 0.01 mm

- Gear profile grinding, gear finishing operations

Product Description

The worm grinding wheel is mainly used for grinding the worm gear and worm gear surface of the reducer, the worm grinding wheel widely used for grinding of small & medium size gear, especially for grinding mass gear.

Features of worm grinding wheel

1. Good stability

2. High grinding accuracy.

3. Small cumulative pitch error

4. Maintain continuous involute and helical gear geometry.

| Sizes(mm) | Specifications | Girnding Machine brand |

| 300*125*160 | 80#-120# JV8 80M/S | Reishauer, Qinchuan |

| 300*145*160 | 80#-120# JV8 80M/S | Reishauer, Qinchuan |

| 300*160*115 | 80#-120# JV8 80M/S | KAPPA, Niles, Qinchuan |

| 320*125*115 | 80#-120# JV8 80M/S | KAPPA, Niles, Qinchuan |

| 350*80*160 | 80#-120# JV8 35M/S | Reishauer, Gleason, Qinchuan |

| 350*84*160 | 80#-120# JV8 35M/S | Reishauer, Gleason, Qinchuan |

| 350*104*160 | 80#-120# JV8 35M/S | Reishauer, Gleason, Qinchuan |

| 400*100*160 | 80#-120# JV8 35M/S | Reishauer, Gleason, Qinchuan |

| 400*104*160 | 80#-120# JV8 35M/S | Reishauer, Gleason, Qinchuan |

Optimized for Precision Gear Grinding

Designed specifically for gear profile grinding and finishing, these vitrified grinding wheels excel in delivering high precision and consistent quality. Their controlled porosity ensures superior coolant flow, preventing thermal damage and extending wheel life. The careful selection of raw materials and manufacturing processes guarantees tight tolerances and unmatched surface finishes, making them ideal for demanding industrial applications.

Versatility and Customization

Available in diameters from 50 mm to 450 mm and supporting various shapes such as disk, ring, and plate, these wheels cater to different gear grinding requirements. OEM and ODM services are provided for special dimension or composition needs, ensuring compatibility with numerous gear grinding machines, both CNC and manual. Strips and rolls can be supplied in standard or customized sizes.

FAQ's of High Quality Abrasive Grinding Wheel for Gear Vitrified Grinding Wheel:

Q: How are these vitrified grinding wheels used in gear profile grinding?

A: These grinding wheels are designed for precision gear profile grinding and finishing operations. When mounted on CNC or manual gear grinding machines, they efficiently remove material, correct gear profiles, and achieve superior accuracy and surface quality thanks to optimized bonding, grain size, and controlled porosity.Q: What materials are these grinding wheels made of?

A: The wheels are constructed from high-grade Aluminum Oxide, Ceramic, or CBN abrasives, with a vitrified (ceramic) bonding matrix. This composition enables high performance, durability, and excellent heat resistance during demanding grinding processes.Q: When should I choose a vitrified grinding wheel over a resin or metal-bonded wheel?

A: Vitrified grinding wheels are preferred for high-precision applications, such as gear profile grinding, where strict tolerances and surface finishes are required. They also offer better heat resistance, longer life, and controlled porosity for improved coolant flow compared to resin or metal-bonded alternatives.Q: Where can these grinding wheels be installed?

A: These grinding wheels are compatible with a wide range of CNC and manual gear grinding machines. They can be applied in automotive, industrial, or machinery manufacturing plants where high-precision gear production is required.Q: What is the process to customize the wheel size or specification?

A: You can specify your gear dimensions, shape, grain size, and other requirements. Our team will provide OEM/ODM solutions, manufacturing the wheels with the exact diameter (50-450 mm), thickness, or custom profiles needed, whether as disk, ring, or plate.Q: What benefits do these wheels offer for high-production environments?

A: Thanks to their robust construction, optimized cooling, high precision (concentricity tolerance 0.01 mm), and extended lifespan, these grinding wheels minimize downtime and maximize throughput, making them perfect for continuous, high-volume gear manufacturing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese