PA Straight Grinding Wheel for Stainless Stain Grinding

50 USD ($)/Piece

Product Details:

- Toughness High

- Shape Flat/Disc

- Hardness Medium to Hard

- Chemical Composition Al2O3, Additives, Binder

- Bonding Vitrified Bond

- Grain Type Pink Fused Alumina

- Backing No Backing

- Click to View more

X

PA Straight Grinding Wheel for Stainless Stain Grinding Price And Quantity

- 50 Piece

- 50 USD ($)/Piece

- 20.00 - 700.00 USD ($)/Piece

PA Straight Grinding Wheel for Stainless Stain Grinding Product Specifications

- Customizable as per order

- Straight Grinding Wheel

- 80, 100, 180

- Aluminum Oxide (PA)

- 100 mm to 400 mm

- Flat/Disc

- High

- No Backing

- Pink Fused Alumina

- Vitrified Bond

- Al2O3, Additives, Binder

- Medium to Hard

Product Description

This straight grinding wheel is made of PA it is vitrified grinding wheel which has better performance than WA or A materials grinding wheel Company Profile iSharp Abrasives Tools Science Institute Is a leading grinding solutions provides from 1991 We have been in this abrasive filed more than 20 years We put a lot of time and energy into creasing tailored abrasive solutions to meet your needs and exceed your expectationsOur products include the cutting disc production line coated abrasive belt conversion line flap disc production line and mounted flap wheel production line Expect these we also have different products such as the cutting disc flap disc oil stone and grinding wheel Our products has exported to many countries such as Russia America Germany Italy Ukraine Singapore Brail Mexico Poland And so on Besides we also have built business relationship with some famous company in this field such as Klingspor Deerfos Sunmight CGW and so on Having been innovating the cutting disc and grinding wheel industry for over 15 years you can count on our products to perform consistently FAQ 1 who are we We are based in Henan China start from 2013sell to Domestic Market2000Western Europe1300Mid East1000Eastern Europe1000North America900South Asia700Southeast Asia600Southern Europe500Central America500Oceania500Africa500South America300Eastern Asia200 There are total about 301500 people in our office 2 how can we guarantee quality Always a preproduction sample before mass production Always final Inspection before shipment 3what can you buy from us grinding wheel making machineflap disc machinecoated abrasive machineryabrasive toolscutting discs 4 why should you buy from us not from other suppliers Experienced abrasives engineers constitute a research team from 1991 Adhering to the Green Efficiency Precision concept we design develop and produce suitable abrasive products provide a complete grinding technology services 5 what services can we provide Accepted Delivery Terms FOBCFRCIFCPTExpress Delivery Accepted Payment CurrencyUSDEURJPYCADAUDHKDGBPCNYCHF Accepted Payment Type TTLCDP DAWestern UnionCash Language SpokenEnglishChineseSuperior Grinding for Stainless Steel

Built specifically for stainless steel applications, the PA Straight Grinding Wheel offers unmatched durability and consistency. Its pink aluminum oxide composition facilitates efficient stock removal and reduces the risk of metallurgical damage, making it perfect for both industrial manufacturing and maintenance workshops.

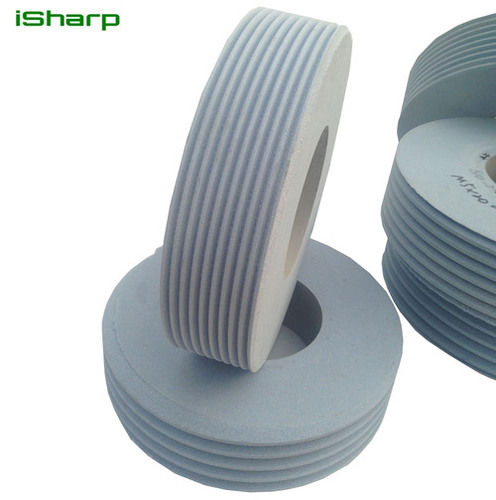

Versatile Sizes and Custom Options

Choose from a range of diameters (100-400 mm) and thicknesses (10-50 mm) to match your precise needs. Customizable strip sizes and the flat/disc shape ensure adaptability for different projects and production requirements. Compatibility with popular bench and pedestal grinders extends its utility across multiple settings.

Reliable Performance and Certification

This grinding wheel is manufactured to meet stringent ISO 9001:2015 standards, ensuring consistent quality and safety. Its vitrified bond and medium-to-hard grade provide a balanced combination of toughness and wheel life, making it a dependable choice for professionals and industries worldwide.

FAQ's of PA Straight Grinding Wheel for Stainless Stain Grinding:

Q: How should the PA Straight Grinding Wheel be used for optimal stainless steel grinding?

A: To achieve optimal results, mount the wheel securely on a compatible bench or pedestal grinder. Operate at or below the maximum speed of 35 m/s. Apply steady, light pressure and allow the wheel's high cutting efficiency and smooth surface finish to work on the material without excessive force.Q: What benefits does the pink fused alumina grain provide in this grinding wheel?

A: Pink fused alumina offers superior toughness and durability, delivering excellent cutting efficiency while minimizing heat buildup. This ensures longer wheel life, consistent surface finishes, and reduced risk of damaging sensitive stainless steel components.Q: When is it necessary to choose different thicknesses or diameters for this grinding wheel?

A: The choice depends on your specific grinding task, machine compatibility, and desired finish. Larger diameters and thicker wheels are better for heavy-duty operations, while smaller, thinner wheels are suitable for precision work or confined spaces. Custom strip sizes can also be specified for unique requirements.Q: Where can this PA Straight Grinding Wheel be applied?

A: Ideal applications include stainless steel fabrication, automotive workshops, metal finishing plants, construction sites, and any location using bench or pedestal grinders. Its versatility and adaptability make it suitable for industrial, export, and maintenance settings.Q: What is the manufacturing process of this grinding wheel?

A: The process involves blending pink aluminum oxide grains with additives and vitrified binder, compacting the mixture into the desired shape, and firing it at high temperatures. The result is a flat/disc-shaped, medium- to hard-wearing wheel capable of withstanding demanding stainless steel grinding operations.Q: Which grain sizes are available and how do they impact wheel performance?

A: Grain sizes 80, 100, and 180 are available. Lower numbers (like 80) offer faster, coarser grinding, while higher numbers (such as 180) provide finer finishes. Select the grain size based on whether your priority is rapid material removal or achieving a smooth final surface.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese