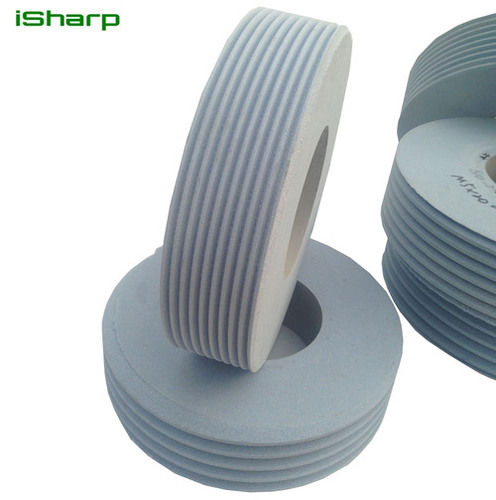

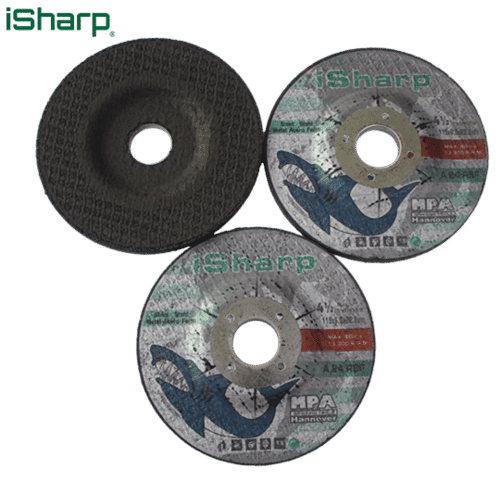

115mm T27 European version high quality depressed center grinding wheel

Product Details:

- Backing Double Reinforced Fiber Glass

- Hardness Medium (R Grade)

- Grain Type Aluminum Oxide

- Chemical Composition Al2O3, phenolic resin, glass fiber

- Shape Flat, Depressed Center

- Toughness High Toughness for Heavy-Duty Grinding

- Bonding Resinoid Bond

- Click to View more

115mm T27 European version high quality depressed center grinding wheel Price And Quantity

- 20000 Piece

- 22 INR/Piece

- 15.00 - 29.00 INR/Piece

- Angle grinders

- 6mm

- 115mm (4.5 inches)

- Smooth grinding, rapid material removal

- 22.23mm

- Grinding steel, stainless steel, cast iron, metal fabrication

- 10 pieces per inner box, 200 pieces per carton

- Black with red label

- 13,300 RPM

- High strength, long life, anti-shock

115mm T27 European version high quality depressed center grinding wheel Product Specifications

- High Toughness for Heavy-Duty Grinding

- Aluminum Oxide

- Resinoid Bond

- 115mm x 6mm x 22.23mm

- A24

- Medium (R Grade)

- Flat, Depressed Center

- Al2O3, phenolic resin, glass fiber

- Double Reinforced Fiber Glass

- T27 Depressed Center

- Aluminum Oxide

- Angle grinders

- 6mm

- 115mm (4.5 inches)

- Smooth grinding, rapid material removal

- 22.23mm

- Grinding steel, stainless steel, cast iron, metal fabrication

- 10 pieces per inner box, 200 pieces per carton

- Black with red label

- 13,300 RPM

- High strength, long life, anti-shock

Product Description

Product Name:115mm T27 European versionhigh quality depressed center grinding wheel

Size: 115*6*22.2mm

Version: European version

Type: T27

Feature:

1. Fast and accurate cutting. The diamond cutting blade is resistant to high temperature, which can reduce vibration and cut straighter and faster. Sharp without collapse, small slit, resistant to cutting and wear.

2. High quality materials and chip free cutting, made of very fine and uniform diamond abrasive particles, the blade has excellent cutting performance, low grinding noise, less dust, less debris, more convenient, safer and longer service life.

3. Diamond cutting wheel DIY tool, used for smooth cutting, chamfering and grinding of glass, jade, crystal, wine bottle, ceramics, ceramic tiles and other materials. Glass cutting disc glass cutting disc.

Company Frofile

ISHARP ABRASIVES TOOLS SCIENCE INSTITUTE is a leading grinding solutions provider in China. Experienced abrasive engineers constitute a research team. Our joint factories develop and manufacture bonded abrasives, coated abrasives, non-woven abrasives and abrasive machines. Adhering to the concept of"Green, Efficiency, Precision", we design, develop and produce suitable abrasive products, machines and offer technology support. iSharp helps the users to improve grinding efficiency and quality, save grinding cost, improve their competitiveness and achieve their value. iSharp's products include resin bonded cutting disc making machines, ceramic bonded grinding wheel making and dressing machines, coated abrasive conversion machine, flap disc production line, mounted flap wheel machines, flanged flap wheel making machines, curing ovens and related materials and accessories.

Expect you enjoy iSharp's quality products and outstanding services!

FAQ

Q1: Does this depressed center cut-off wheel has any safety certifications?

A1.Yes, we have ISO and MPA certifications.

Q2: What package do you use?

A2: Packing ways differ for different wheels. We offer shrink packing, plastic box packing, iron box packing, normal carton packing and color box packing.

Q3: Do you accept OEM order?

A3: Yes, OEM order is accepted. We can also help to design label for you for free.

Q4: Can you provide free samples?

A4: Yes, we can offer free samples for quality testing, but the customer should pay the shipping freight.

Q5: How to ensure product quality?

A5: Raw materials selected strictly, control quality from the source. Each step has to pass the corresponding quality testing, such us, balance test, cutting performance test, grinding performance test, rotation strength test, etc...

High Performance and Versatility

This grinding wheel is suitable for use on steel, stainless steel, and cast iron, making it a versatile option for metal fabrication and industrial maintenance. The T27 flat, depressed center design ensures safe and stable operation with angle grinders, delivering high material removal rates with minimal vibration.

Engineered for Strength and Durability

Manufactured with premium aluminum oxide grains and reinforced with double layers of fiber glass, this wheel withstands demanding tasks and heavy-duty grinding. The resinoid bond and R-grade hardness provide a medium, balanced cut, ensuring long-lasting performance and resistance to shocks during operation.

User-Friendly Packaging and Application

Each inner box contains 10 pieces, with 200 wheels per export carton, facilitating easy storage and distribution for suppliers and traders. The black finish with a red label aids quick identification in busy work environments, while the wheel is compatible with any standard angle grinder fitted for a 115mm disc.

FAQ's of 115mm T27 European version high quality depressed center grinding wheel:

Q: How should I use the 115mm T27 depressed center grinding wheel for optimal performance?

A: For best results, mount the wheel securely on a compatible angle grinder with a 22.23mm arbor, operate at or below the maximum speed of 13,300 RPM, and apply steady, even pressure. Use at an appropriate angle for your application to achieve smooth grinding and rapid material removal.Q: What types of materials can this grinding wheel effectively grind?

A: This wheel is designed for grinding ferrous metals, including steel, stainless steel, and cast iron. Its high-quality aluminum oxide grain and medium hardness make it effective for heavy-duty industrial applications in metal fabrication and repair.Q: When should I replace the grinding wheel?

A: Replace the grinding wheel when it shows signs of excessive wear, reduced cutting efficiency, or visible damage such as cracks or chips. Regular inspection before use is essential to ensure safety and consistent performance.Q: Where can this grinding wheel be used?

A: It is suitable for use in fabrication workshops, metalworking facilities, construction sites, and maintenance operations. Distributors, exporters, manufacturers, suppliers, and traders in China and internationally rely on it for efficient grinding tasks.Q: What is the manufacturing process behind these grinding wheels?

A: These wheels are produced by bonding aluminum oxide grains with phenolic resin and layering double reinforced fiber glass. The combination results in a high-strength, shock-resistant tool with a smooth surface finish suitable for demanding grinding tasks.Q: How does the anti-shock feature benefit the user?

A: The double reinforced fiber glass backing and resinoid bond provide enhanced shock resistance, reducing the risk of breakage during heavy-duty grinding. This offers added safety and comfort for the operator, even during prolonged use.Q: What are the advantages of using this grinding wheel over other types?

A: Compared to standard wheels, this T27 type offers prolonged wheel life, high toughness, rapid material removal, and smooth grinding. Its anti-shock design and medium hardness make it a reliable option for both precision and high-volume industrial work.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese