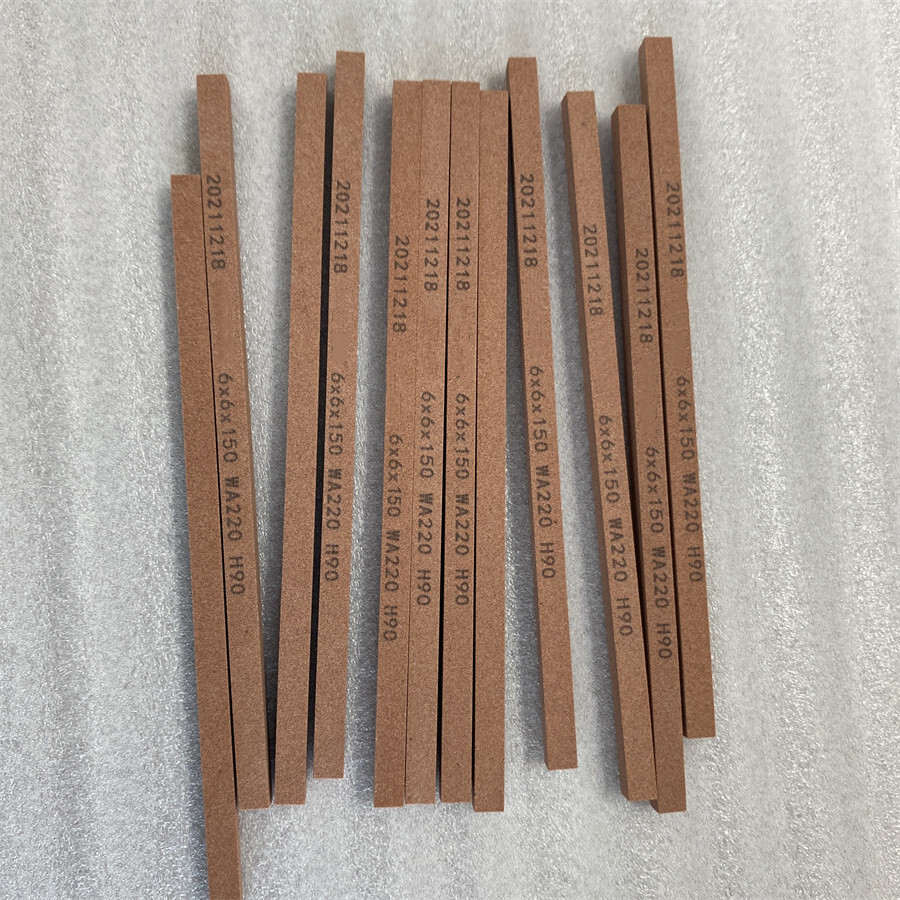

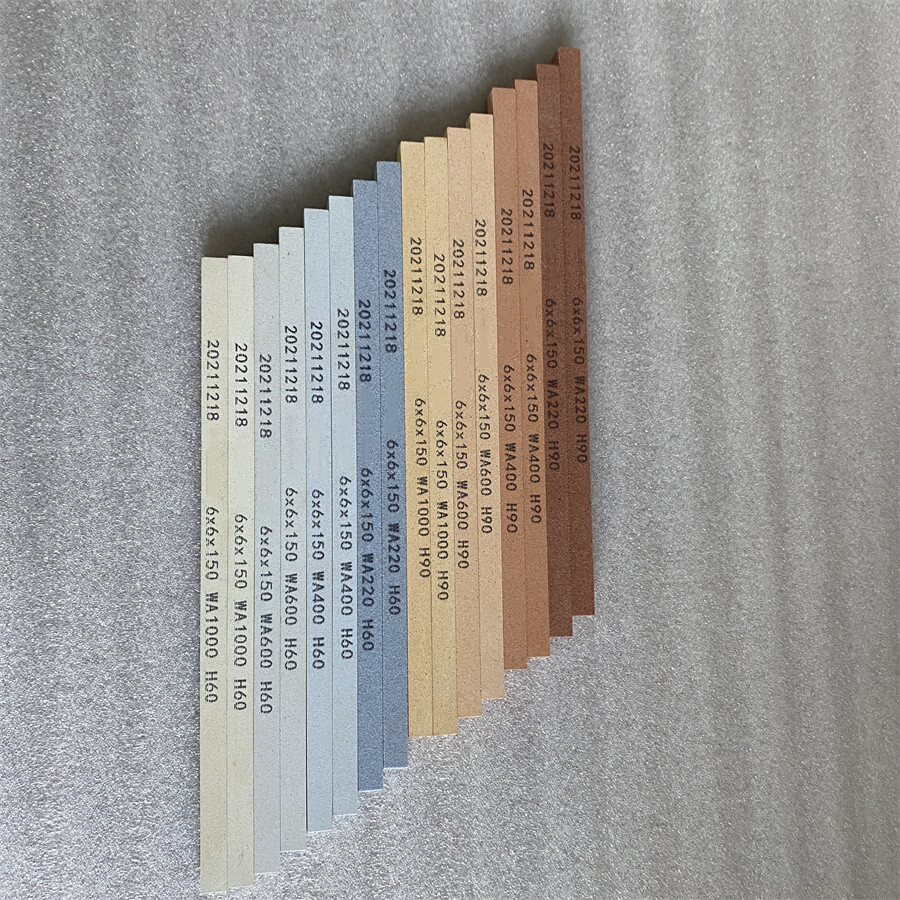

Mold polishing stone

Product Details:

- Toughness High fracture toughness for extended use

- Hardness Medium to Hard (approx. 75-85 HRc)

- Shape Rectangular (strip/bar)

- Chemical Composition High-purity abrasive minerals with binder matrix

- Bonding Resin Bonded

- Backing No separate backing; solid stone

- Grain Type Aluminum Oxide or Silicon Carbide

- Click to View more

Mold polishing stone Price And Quantity

- 0.5 USD ($)/Piece

- 300 Piece

- Light grey or white

- Compatible with oil- or water-based lubricants

- Up to 450°C

- Individual or bulk, foam wrapped

- Precision polishing of mold cavities and metal surfaces

- Manual or mechanical polishing of die and mould steels, alloys, carbide, etc.

- Mirror or satin finish depending on grit

- Fine to coarse

Mold polishing stone Product Specifications

- High fracture toughness for extended use

- Mold Polishing Stone

- Medium to Hard (approx. 75-85 HRc)

- Fine-grain abrasive ceramic or synthetic stones

- 6 mm x 3 mm x 150 mm (examples: 4 mm x 6 mm x 150 mm, 3 mm x 6 mm x 150 mm)

- #120 to #1200

- Rectangular (strip/bar)

- High-purity abrasive minerals with binder matrix

- No separate backing; solid stone

- Aluminum Oxide or Silicon Carbide

- Resin Bonded

- 150 mm x 6 mm x 3 mm (typical strip size, may vary)

- Light grey or white

- Compatible with oil- or water-based lubricants

- Up to 450°C

- Individual or bulk, foam wrapped

- Precision polishing of mold cavities and metal surfaces

- Manual or mechanical polishing of die and mould steels, alloys, carbide, etc.

- Mirror or satin finish depending on grit

- Fine to coarse

Product Description

*Various size and grits for your choice, customization supported.

| Thickness (mm) |

|

Width (mm) |

Length |

Thickness (inch) |

Width (inch) |

Length (inch) |

Abrasive |

Grit |

||

|

3 |

6 |

150 |

1/8" |

1/4" |

6" |

Al2O3 |

#120, #180

|

|

|

3 |

13 |

150 |

1/8" |

1/2" |

6" |

Al2O3 |

||

|

3 |

25 |

150 |

1/8" |

1" |

6" |

Al2O3 |

||

|

6 |

6 |

150 |

1/4" |

1/4" |

6" |

Al2O3 |

||

|

6 |

13 |

150 |

1/4" |

1/2" |

6" |

Al2O3 |

||

|

6 |

25 |

150 |

1/4" |

1" |

6" |

Al2O3 |

||

|

13 |

1.5 |

150 |

1/2" |

1/16" |

6" |

Al2O3 |

||

|

13 |

13 |

150 |

1/2" |

1/2" |

6" |

Al2O3 |

||

|

13 |

25 |

150 |

1/2" |

1" |

6" |

Al2O3 |

||

|

10 |

10 |

150 |

3/8" |

3/8" |

6" |

Al2O3 |

Outstanding Precision for Mold Polishing

Achieve exceptional surface finishes on mold cavities and metal components with this advanced mold polishing stone. Its high-purity abrasive minerals and robust resin bonding allow for consistent performance in manual or mechanical polishing tasks, replacing the need for multiple finishing tools. A range of grit grades gives you control, from coarse material removal to fine mirror-polish detailing.

Versatile Compatibility and Durability

Designed to adapt, these stones perform optimally with both water- and oil-based lubricants, ensuring flexibility in various environments. With a temperature resistance up to 450C and a hardness rating between 75-85 HRc, their durability suits prolonged use on die and mold steels, alloys, and carbide without premature wear or deformation.

Flexible Sizing and Packaging Solutions

Available in various strip sizes and packaged either individually or in bulk, these stones accommodate the diverse requirements of manufacturers, distributors, and suppliers. The foam-wrapped protection in packaging ensures that stones arrive intact and ready-to-use. This makes them ideal for both small workshops and large export operations.

FAQ's of Mold polishing stone:

Q: How should I use mold polishing stones to achieve the optimal surface finish?

A: For best results, select the appropriate grit grade for your desired finish-use coarser grits for initial material removal and finer grits (#1200) for mirror or satin polish. Apply either manually or with a mechanical tool, using oil or water-based lubricants to reduce friction and extend stone life.Q: What types of materials can be polished with these stones?

A: These stones are suitable for precision polishing on die and mold steels, hard alloys, and carbide, thanks to their high-purity abrasive composition and strong resin bonding.Q: When is it recommended to switch from coarse to fine grit stones during polishing?

A: Start with a coarse grit to remove surface irregularities and switch to finer grades sequentially as the surface smooths. Transitioning to #1200 grit ensures a high-gloss mirror finish or fine satin texture, depending on your requirements.Q: Where are these mold polishing stones typically used?

A: They are commonly utilized in tool rooms, mold fabrication facilities, and maintenance departments across manufacturing industries-ideal for precision machining and repair of molds and dies.Q: What benefits do these stones offer over alternative polishing tools?

A: These stones provide high fracture toughness for extended service life, uniform abrasive action, compatibility with both oil- and water-based lubricants, and the ability to withstand high operational temperatures without deformation.Q: What is the process for maintaining the stones during and after use?

A: Clean the stones with a compatible solvent or detergent after each use to remove lodged debris. Store them in their foam-wrapped packaging to prevent contamination or damage between uses.Q: Are different stone sizes and packaging options available for bulk orders?

A: Yes, a range of strip sizes is offered, and packaging can be tailored to individual or bulk requirements, ensuring safe transport and efficient inventory management for both distributors and end users.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese