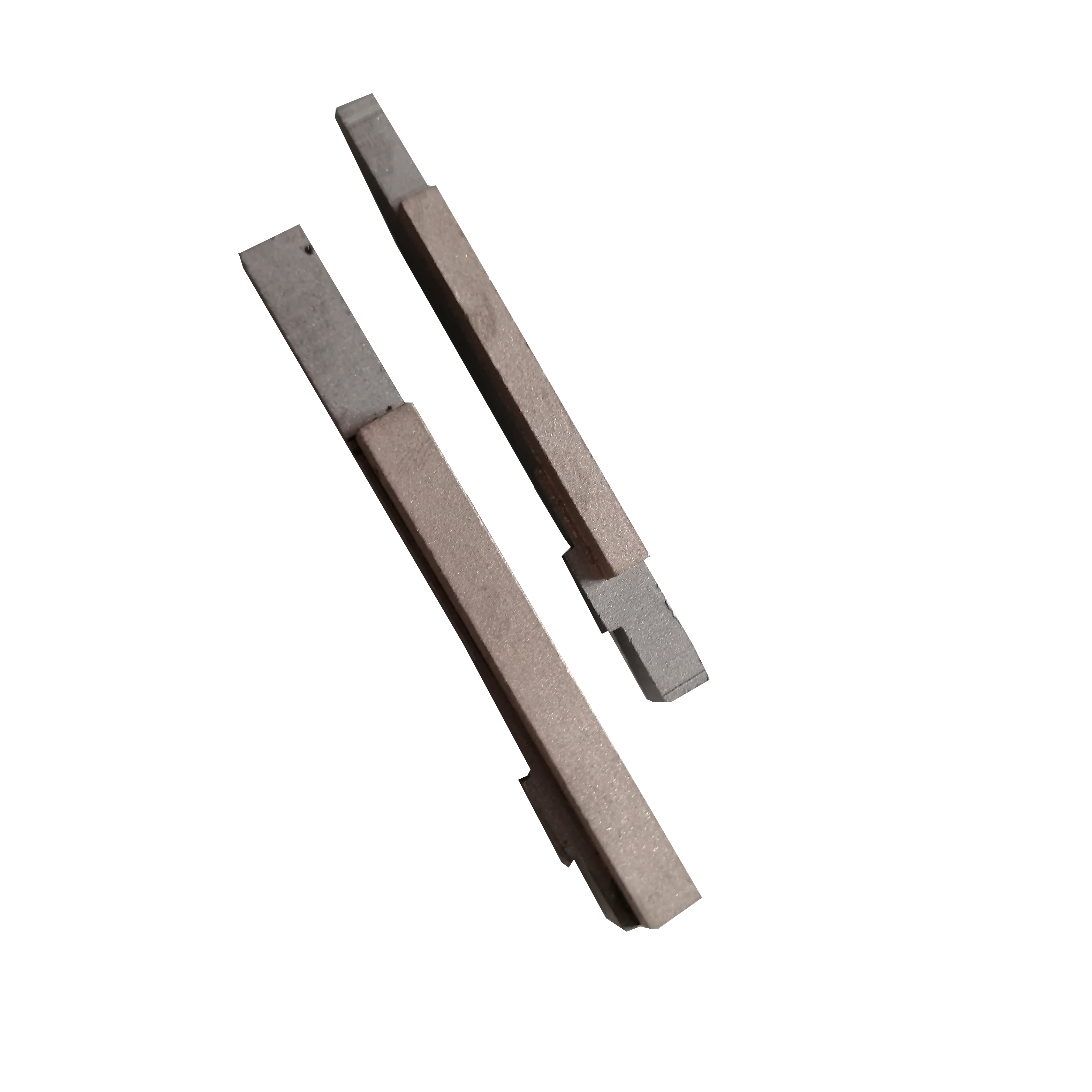

iSharp diamond honing stone for cylinder polishing dressing

5 USD ($)/Piece

Product Details:

- Shape Rectangular/Bar

- Toughness High impact resistance

- Grain Type Synthetic Diamond

- Chemical Composition Diamond (C), Binder (Fe, Co, Ni, Resin)

- Hardness Super Hard

- Backing Steel strip core

- Bonding Metal/Resin Bond

- Click to View more

X

iSharp diamond honing stone for cylinder polishing dressing Price And Quantity

- 500 Piece

- 5 USD ($)/Piece

- 5mm to 30mm

- Extended, designed for multiple re-dressings

- Applies to all standard vertical and horizontal honing machines

- Up to 300°C

- 50mm to 210mm

- Ideal for engine cylinder liners, hydraulic cylinders, and precision bore finishing

- ±0.05mm

- FEPA/JIS

- 3mm to 13mm as required

iSharp diamond honing stone for cylinder polishing dressing Product Specifications

- High impact resistance

- Super Hard

- Synthetic Diamond

- Diamond (C), Binder (Fe, Co, Ni, Resin)

- Rectangular/Bar

- Diamond abrasive with high-grade steel base

- Honing Stone for Cylinder Polishing

- Customizable; typically available in lengths up to 210mm

- Metal/Resin Bond

- As per order specification

- #80 to #4000

- Steel strip core

- 5mm to 30mm

- Extended, designed for multiple re-dressings

- Applies to all standard vertical and horizontal honing machines

- Up to 300°C

- 50mm to 210mm

- Ideal for engine cylinder liners, hydraulic cylinders, and precision bore finishing

- ±0.05mm

- FEPA/JIS

- 3mm to 13mm as required

Product Description

Our products has exported to many countries such as Russia America Germany Italy Ukraine Singapore Brazil Mexico Poland And so on Besides we also have built business relationship with some famous company in this field such as Klingspor Deerfos Sunmight CGW and so on Having been innovating the cutting disc and grinding wheel industry for over 15 years you can count on our products to perform consistentAny questions please contact us

Nancy Lu iSharp Abrasives Tools Science Institute

Add A2507 Kaixuanmen Tongbai S RdZhengzhou Henan 450006 China

FAQ

Q1 Are you a manufacturer or a trading company

We are a professional manufacturer of abrasive tools with the whollyowned trading company as well You are warmly welcome to have an onthespot investigation to our factory

Yes OEM services are available and we have rich experience in OEM

Yes free samples is available for quality checking before orders

Yes we have

The quality of the product is the fundamental to serve our customers well One the one hand we insist on innovation introduction outstanding talents equipment and technology to fully achieve the quality of products to meet customers needs requirements on the other hand we adopt advanced management method especially the quality test management

TT 30 as deposit and 70 before delivery and different quantities decide different payment terms Well show you the photos of the products and packages before you pay the balance payment

Generally it will take 15 to 40 working days after receiving your advance payment But the specific delivery time depends on the items and the quantity of your order

Can be usedfor the honing process of materials like cast ironsilicon aluminumalloybabbitt alloybronzebrassetc

Made of syntheticdiamond and bond powder through process of mixingpressingsintering andgrindingHigh grinding efficiencysmall wearingeconomic and convenient to use

Suitable for roughhoningplateau honingslide honinghelical slide honing etcHoned cylinder withquality cross hatch meets the automobile emission limit standard of ChinaVChina VIEuro 5Euro 6 etc

Widely applied inengine cylinder liners of various brands like MercedesBenzCarterJohnDeereFiatCumminsSteyrInternational HarvesterIvecoVoithDaimlerAGCOSinotrukWeichaiYuchcaiFAWDEChaoyangDieseletc

Steadily used onhoning machine tools such as GerhringSunnenNagelKunjiiangDaheetc

Company Profile

ISHARP ABRASIVES TOOLS SCIENCE INSTITUTE is a leading grinding solutions provider in China Experienced abrasive engineers constitute a research team Our joint factories develop and manufacture bonded abrasives coated abrasives nonwoven abrasives and abrasive machines Adhering to the concept ofGreen Efficiency Precision we design develop and produce suitable abrasive products machines and offer technology support iSharp helps the users to improve grinding efficiency and quality save grinding cost improve their competitiveness and achieve their value iSharps products include resin bonded cutting disc making machines ceramic bonded grinding wheel making and dressing machines coated abrasive conversion machine flap disc production line mounted flap wheel machines flanged flap wheel making machines curing ovens and related materials and accessories

Expect you enjoy iSharps quality products and outstanding services

Packaging

1 Shrinking plastic bagsmall boxcarton Neutral Colorful

2 Customized packaging available

Shipping Delivery

1 Small samples shipping by express DHL FEDEX THT

2 Big order by sea as per customers request

FAQ

Q1 Does this depressed center cutoff wheel has any safety certifications

A1Yes we have ISO and MP

A certifications

Q2 What package do you use

A2 Packing ways differ for different wheels We offer shrink packing plastic box packing iron box packing normal carton packing and color box packing

Q3 Do you accept OEM order

A3 Yes OEM order is accepted We can also help to design label for you for free

Q4 Can you provide free samples

A4 Yes we can offer free samples for quality testing but the customer should pay the shipping freight

Q5 How to ensure product quality

A5 Raw materials selected strictly control quality from the source Each step has to pass the corresponding quality testing such us balance test cutting performance test grinding performance test rotation strength test etc

Unmatched Precision and Endurance

Designed for multiple re-dressings, the iSharp diamond honing stone provides consistent and precise finishing. Its hardness and impact resistance ensure outstanding longevity, making it the go-to choice for demanding industrial applications.

Versatile Sizing and Application

With widths from 5mm to 30mm and lengths up to 210mm, this honing stone fits a wide range of cylinder polishing machines and setups. Customizable strip sizes and bonds allow flexibility for unique operational requirements.

FAQ's of iSharp diamond honing stone for cylinder polishing dressing:

Q: How can the iSharp diamond honing stone be used for cylinder polishing and dressing?

A: The iSharp honing stone is ideal for polishing and dressing engine cylinder liners, hydraulic cylinders, and completing precision bore finishing. It is compatible with all standard vertical and horizontal honing machines and requires simple mounting per machine design.Q: What grain sizes are available and how do I select the appropriate grit for my application?

A: Grain sizes range from #80 to #4000 according to FEPA/JIS standards. Selection depends on the desired finish; coarser grits (#80) remove material quickly, while finer grits (#4000) deliver a smooth, precise finish.Q: When should the honing stone be re-dressed or replaced?

A: Thanks to its extended service life and high wear resistance, the iSharp honing stone is designed for multiple re-dressings. Re-dressing is needed when performance declines, but frequent replacement is rarely required under normal operating conditions.Q: Where can I use this honing stone, and what machine compatibility does it offer?

A: This honing stone is suitable for industrial environments and is compatible with all standard vertical and horizontal honing machines. Its adaptability makes it perfect for various settings requiring cylinder polishing.Q: What is the process for customizing strip or roll sizes for specific needs?

A: Customers can specify strip and roll dimensions within provided ranges, including widths (5mm-30mm), thicknesses (3mm-13mm), and lengths (up to 210mm). Orders are fulfilled based on these specifications to ensure an exact fit for unique applications.Q: What are the benefits of using the iSharp diamond honing stone?

A: Key benefits include extended service life, tight dimensional tolerances (0.05mm), high impact resistance, consistent performance at temperatures up to 300C, and customizable sizing for various applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese