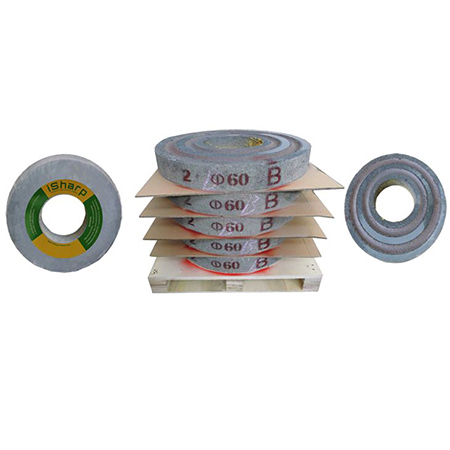

स्टील बॉल ग्राइंडिंग व्हील

उत्पाद विवरण:

- बेरहमी High

- शेप Round / Wheel

- अनाज का प्रकार Coarse, Medium, Fine

- बॉन्डिंग Vitrified Bond

- रासायनिक संरचना Al2O3, SiC, Binders

- कठोरता H to N

- मटेरियल Aluminum Oxide, Silicon Carbide

- अधिक देखने के लिए क्लिक करें

स्टील बॉल ग्राइंडिंग व्हील मूल्य और मात्रा

- 1

- सेट/सेट्स

- सेट/सेट्स

स्टील बॉल ग्राइंडिंग व्हील उत्पाद की विशेषताएं

- Coarse, Medium, Fine

- Vitrified Bond

- Aluminum Oxide, Silicon Carbide

- Centerless Grinding Wheel

- Round / Wheel

- H to N

- 46 - 120 mesh

- Al2O3, SiC, Binders

- High

- Customizable as per application

स्टील बॉल ग्राइंडिंग व्हील व्यापार सूचना

- प्रति महीने

- दिन

उत्पाद वर्णन

To become a leading firm in this domain, involved in manufacturing and supplying premium grade Steel Ball Grinding Wheel, which is mainly suitable to be used to grind and blend materials. Provided wheel finds its usefulness in mineral dressing processes, paints, ceramics and pyrotechnics. The offered wheel is made using top quality components by adept professionals at the highly modern production unit. The provided wheel is safely packed to prevent damage during transit. In addition to this, offered Steel Ball Grinding Wheel can be bought from us in various specifications as per clients demand at industrial leading prices.

Technical Specification

| D | T | H | Abrasives |

| 720 | 80 | 290 | A/C, A/GC, WA/GC |

| 800 | 100 | 290 | |

| 100 | 360 | ||

| 100 | 450 | ||

| 820 | 110 | 305 | |

| 900 | 110 | 360 |

| D | T | H | Abrasives | Grit |

| 660 | 30~60 | 440 | GC, WA | (JIS) 1000,2000, 3000,4000,6000 |

| 700 | 30~60 | 420 | ||

| 720 | 30~90 | 300 | ||

| 800 | 30~90 | 350,390,440 |

Customizable Sizes & Versatile Applications

Our steel ball grinding wheels are available in diameters from 200 mm to 600 mm and thicknesses between 10 mm and 75 mm. Custom sizing ensures the perfect fit for your equipment and application, enhancing versatility and productivity. These wheels are ideal for use in steel ball manufacturing and finishing lines, delivering consistent quality results in every rotation.

Advanced Materials for Superior Performance

Manufactured from high-grade aluminum oxide and silicon carbide, our grinding wheels feature a robust vitrified bond for durability. These materials ensure high toughness, excellent abrasion resistance, and a long service life, even under rigorous operating conditions. Choose from coarse, medium, or fine grains to match your specific grinding requirements.

Precision Finish and High Safety Standards

Each wheel is engineered for a smooth, precise surface finish on steel balls. Designed for centerless grinding, these wheels operate effectively at speeds up to 35 m/s. Rigorous quality controls and chemical formulations (Al2O3, SiC, binders) guarantee reliable, safe, and stable performance, meeting the strict demands of industrial processes.

FAQs of Steel Ball Grinding Wheel:

Q: How is the steel ball grinding wheel used in manufacturing processes?

A: These grinding wheels are mainly used for centerless grinding operations to shape and finish the surface of steel balls. The wheels are installed on specialized grinding machines where they remove excess material and produce a smooth, uniform finish on each steel ball.Q: What material compositions are available for these grinding wheels?

A: The wheels are constructed from aluminum oxide (Al2O3) or silicon carbide (SiC), with vitrified bonds and durable binders that provide high toughness and resilience. Choice of material depends on your specific steel ball application and desired finish quality.Q: When should I select a coarse, medium, or fine grain type?

A: Grain selection is determined by the desired surface finish and removal rate. Coarse grains (46-60 mesh) are best for rapid material removal; medium grains (70-100 mesh) are suited for balanced grinding and finishing; fine grains (up to 120 mesh) deliver the smoothest finishes.Q: Where can these grinding wheels be supplied, and are export options available?

A: We supply and export these grinding wheels globally, with distributor and trader networks based in China. Customization and shipping options are available to meet your operational requirements no matter your location.Q: What benefits do these grinding wheels offer over standard options?

A: Our grinding wheels offer high abrasion resistance, longer operational life, and precise, smooth surface finishes. The vitrified bonding and customizable shapes and sizes ensure optimal performance tailored to specific steel ball grinding applications.Q: How can I customize a wheel to suit my unique application needs?

A: Simply provide the required diameter, thickness, and roll size specifications. We will manufacture the wheel tailored to your grinding machine and process requirements, ensuring maximum efficiency and effectiveness in your operations.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese