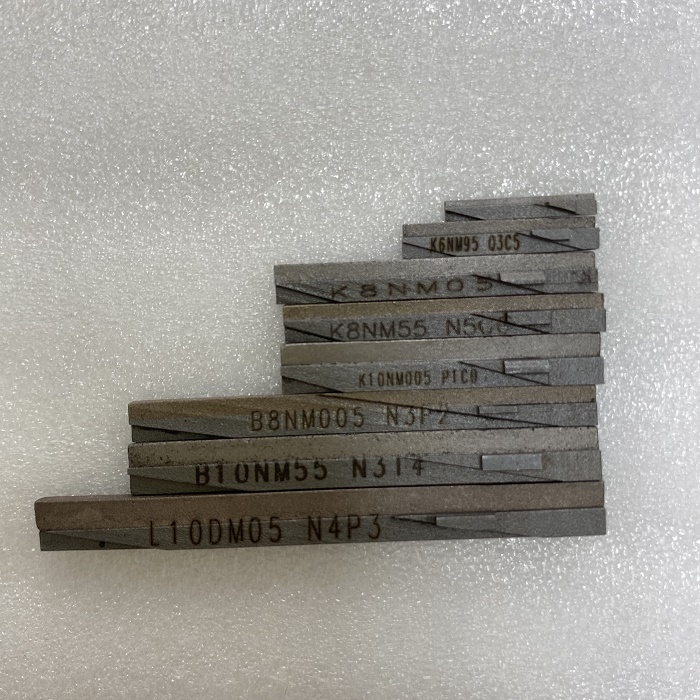

Diamond honing stone

0.5 USD ($)/Piece

Product Details:

- Toughness High impact and abrasion resistance

- Shape Rectangular

- Chemical Composition Diamond (C), metallic binder

- Grain Type Monocrystalline diamond

- Hardness Up to 9.5 Mohs

- Bonding Metal Bonded

- Backing Steel or carbide base

- Click to View more

X

Diamond honing stone Price And Quantity

- 20 Piece

- 0.5 USD ($)/Piece

- Individual blister pack with anti-rust protection

- Resinoid and vitrified options upon request

- Extended lifespan for large batch processing

- 0.5 mm 2.0 mm

- Suitable for horizontal & vertical honing machines

- 30 m/s

- Engineered low porosity for consistent cutting

- Precision honing of automotive, hydraulic, and industrial cylinders

- Up to 500C

Diamond honing stone Product Specifications

- Monocrystalline diamond

- Available from 80 mesh to 2000 mesh

- High impact and abrasion resistance

- Rectangular

- Diamond (C), metallic binder

- 200 mm x 25 mm x 6 mm

- High-quality synthetic diamond

- Up to 9.5 Mohs

- Metal Bonded

- Steel or carbide base

- Honing Stone

- Customizable to application

- Individual blister pack with anti-rust protection

- Resinoid and vitrified options upon request

- Extended lifespan for large batch processing

- 0.5 mm 2.0 mm

- Suitable for horizontal & vertical honing machines

- 30 m/s

- Engineered low porosity for consistent cutting

- Precision honing of automotive, hydraulic, and industrial cylinders

- Up to 500C

Product Description

The CBN engine cylinder honing stones polishing stones are made of synthetic diamond and metal powder through the process of mixing, pressing, sintering, and grinding. High grinding efficiency, small wearing, economic, and convenient to use.The engine cylinder diamond honing stone grinding stone manufactured is suitable for rough honing, plateau honing, slide honing, helical slide honing, etc. The cross hatches after the honing process will meet the automobile emission requirements of China 5, China 6, and Euro 5 Euro 6, making more efforts for decarbonizing targets.

Versatile Performance for Critical Applications

These diamond honing stones are ideal for precision machining in the automotive, hydraulic, and industrial sectors. Engineered for use at high temperatures and speeds, they offer superior wear resistance and consistent honing results, making them a preferred choice for both horizontal and vertical honing machines. Suitable for custom cylinder diameters and different grit specifications.

Advanced Material Composition and Design

Constructed from high-quality synthetic monocrystalline diamond, the stones deliver exceptional hardness and toughness. The metallic bonded structure ensures stability, while the engineered low porosity enhances both performance and surface finish consistency. Custom sizes and grit options allow for precision adaptation to specific industrial processes.

FAQ's of Diamond honing stone:

Q: How do I choose the appropriate grit size for my diamond honing stone application?

A: Select the grit size based on the required finish and the material of your workpiece. Coarse grits (80-200 mesh) are suitable for rapid material removal, while finer grits (up to 2000 mesh) deliver a smoother surface for precision applications, such as finishing hydraulic or automotive cylinders.Q: What is the process for using a diamond honing stone in batch cylinder honing?

A: Install the honing stone in a compatible horizontal or vertical honing machine. Set the appropriate speed (up to 30 m/s) and temperature controls (up to 500C). Use consistent coolant flow and follow your standard honing parameters. The stone's engineered low porosity ensures uniform cutting and long-lasting performance throughout large batch operations.Q: When should I replace the diamond honing stone?

A: Replace the honing stone when you notice significant wear, reduced cutting efficiency, or uneven finishes on your parts. The extended service life supports large-scale processing, but regular inspection after each batch is recommended to maintain precision and quality.Q: Where can these diamond honing stones be used?

A: They are widely used in the automotive, hydraulic, and general industrial sectors for honing cylinder bores. Suitable for factories, repair workshops, and high-volume manufacturing plants that require consistent, high-quality finishes on metal surfaces.Q: What benefits does a metal bonded, low porosity diamond honing stone offer?

A: The metal bonding provides exceptional durability and stability, supporting high impact and abrasion resistance. Engineered low porosity ensures consistent cutting action, reduces the risk of glazing, and improves heat dissipation, resulting in longer tool life and better finish uniformity.Q: How is the diamond honing stone packaged for shipping and storage?

A: Each honing stone is individually blister-packed with anti-rust protection, ensuring safe transport and storage while preserving tool integrity and chemical composition.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese