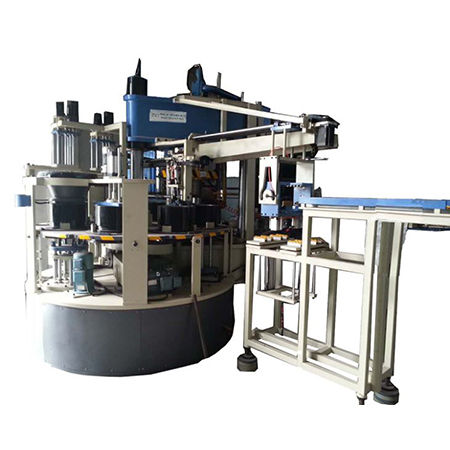

Vitrified Grinding Wheel Moulding Press

Product Details:

- Hardness Adjustable hardness settings for different wheel specifications

- Toughness High mechanical strength and impact resistance

- Shape Rectangular and circular die configurations

- Chemical Composition Engineered steel with anti-rust treatment

- Backing Heavy-duty reinforced steel base

- Grain Type Aluminum Oxide, Silicon Carbide

- Bonding Vitrified Bonding

- Click to View more

Vitrified Grinding Wheel Moulding Press Price And Quantity

- 1 Set

- 0.15 - 7000.00 USD ($)/Set

- 5000-7000 USD ($)/Set

- Emergency stop, interlock system, safety guarding

- Integrated heating plate for better moulding

- Semi-automatic / Fully automatic

- Varies as per press model

- 380V, 50Hz, 3 Phase

- 50 - 150 wheels per shift (variable with size and type)

- Custom sizes available for different wheel diameters

- Moulding of vitrified, resin, and magnesite bonded grinding wheels

- Approx. 30-60 seconds per cycle (depends on wheel size)

- PLC based automatic control

- High-efficiency hydraulic unit with overload protection

- 40 to 200 tons

Vitrified Grinding Wheel Moulding Press Product Specifications

- Varies as per wheel dimensions

- Adjustable hardness settings for different wheel specifications

- Automatic Hydraulic Moulding Press

- Engineered steel with anti-rust treatment

- Customizable as per requirement

- Aluminum Oxide, Silicon Carbide

- High mechanical strength and impact resistance

- Heavy-duty reinforced steel base

- Available from 4 to 120 grit

- High-grade alloy steel

- Vitrified Bonding

- Rectangular and circular die configurations

- Emergency stop, interlock system, safety guarding

- Integrated heating plate for better moulding

- Semi-automatic / Fully automatic

- Varies as per press model

- 380V, 50Hz, 3 Phase

- 50 - 150 wheels per shift (variable with size and type)

- Custom sizes available for different wheel diameters

- Moulding of vitrified, resin, and magnesite bonded grinding wheels

- Approx. 30-60 seconds per cycle (depends on wheel size)

- PLC based automatic control

- High-efficiency hydraulic unit with overload protection

- 40 to 200 tons

Vitrified Grinding Wheel Moulding Press Trade Information

- 1000 Set Per Month

- 30 Days

Product Description

To fulfill the diverse requirements of our valuable clients, we have been engaged in offering supreme grade Vitrified Grinding Wheel Moulding Press. Offered press is highly appreciated among clients due to its trouble free working. This press is made using top-notch quality components under observation our dexterous professionals with cutting edge techniques. The provided press is mainly used for making grinding wheel in industrial places. This press is equipped with a motor and other components to ensure its flawless working. In addition, offered Vitrified Grinding Wheel Moulding Press is safely packed to prevent damage during transit.

Technical Specification

| Model | PRS-P26T200D10 | PRS-R8T500D20 | PRS-RCT750D50 |

| Grinding Wheel Diameter | Max 250mm | Max 500mm | Max 1250mm |

| Grinding Wheel Thickness | Max 65mm | Max 200mm | Max 200mm |

| Grinding Wheel Shape | T1, T4, T6, T11, T12 | T1 | T1 |

| Structure | Pusher type | Pusher type | Reciprocating type |

| Work Station | 20 -26 | 8 | 3 |

| Rating Press | 100T/125T/150T/200T | 300T/400T/500T | 400T/500T/600T/750T |

| Control Mode | PLC control, touch screen display | PLC control, touch screen display | PLC control, touch screen display |

| Each Leveling Micro-lift | Servo motor, 0.05-3.00mm | Servo motor, 0.05-3.00mm | Servo motor, 0.05-3.00mm |

| Leveling Mode | Scraper blades and forks rising speed and process can be set freely. | Scraper blades and forks rising speed and process can be set freely. | Scraper blades and forks rising speed and process can be set freely. |

| Capacity | 100-500pcs / 8hours | 30-80pcs / 8hours | 10-50pcs / 8hours |

| Operators | 1-4persons | 1-3persons | 2-4persons |

| Installed Power | 15-20KW | 25-31KW | 28-40KW |

| Consumption Power | 5-8KW | 8-12KW | 9-15KW |

| Size(L x W x H) | 4500 x 1650 x 2750mm | 6000 x 1860 x 2900mm | 2800 x 6900 x 2800mm |

| Weight | 4000-7000kgs | 15000-19000kgs | 15000-24000kgs |

Precise Control and Performance

Equipped with a sophisticated PLC-based control system, this press ensures precise parameter management and repeatable results for every molding cycle. The integrated heating plate and adjustable hardness settings enable high consistency and quality across varying grinding wheel types and sizes.

Versatile Applications

Designed to mold vitrified, resin, and magnesite bonded grinding wheels, the press accommodates a range of grain typesfrom aluminum oxide to silicon carbideand supports grain sizes from 4 to 120 grit. Custom die and roll sizes make it suitable for diverse manufacturing requirements.

Safety and Efficiency Prioritized

The machine incorporates vital safety features, such as emergency stop, interlock systems, and comprehensive guarding. Its high-efficiency hydraulic unit and variable production capacity (50150 wheels per shift) make it a reliable solution for distributors, exporters, manufacturers, suppliers, and traders.

FAQs of Vitrified Grinding Wheel Moulding Press:

Q: How does the PLC-based control system enhance the moulding press operation?

A: The PLC-based automatic control system streamlines the molding process by delivering precise command over pressing cycles, temperature, and pressure. This automation minimizes human error, enables fast changeovers between settings, and improves both safety and productivity.Q: What materials and wheel types can this press handle?

A: This molding press is designed for vitrified, resin, and magnesite bonded grinding wheels. It supports a variety of grain types, including aluminum oxide and silicon carbide, with grain sizes ranging from 4 to 120 grit, and can be customized for different diameters and specifications.Q: When should I choose semi-automatic versus fully automatic operating modes?

A: The semi-automatic mode is recommended for prototype batches, specific customizations, or when operator control is necessary. Fully automatic mode is ideal for high-volume, consistent production, where minimal human involvement is desired for maximum efficiency.Q: Where is the Vitrified Grinding Wheel Moulding Press typically used?

A: This press is commonly used in manufacturing facilities that produce industrial grinding wheels, such as those operated by distributors, exporters, manufacturers, suppliers, and traders, particularly in regions like China where high-volume wheel production is in demand.Q: What is the moulding process using this press?

A: The process involves placing raw materials into a custom die, followed by automatic or semi-automatic pressing under high pressure (40200 tons). The integrated heating plate ensures proper bonding, after which the molded wheel is ejected and ready for post-molding processes.Q: What are the main benefits of using this hydraulic moulding press?

A: Key advantages include high mechanical strength, adjustable hardness for various wheel specs, robust safety features, rapid cycle times (30-60 seconds), high production capacity, and versatility in wheel shapes and grain types.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese