Superfinishing Grinding Stones

0.5 USD ($)/Piece

Product Details:

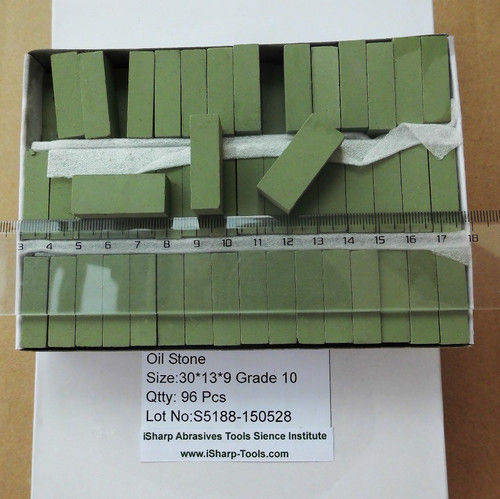

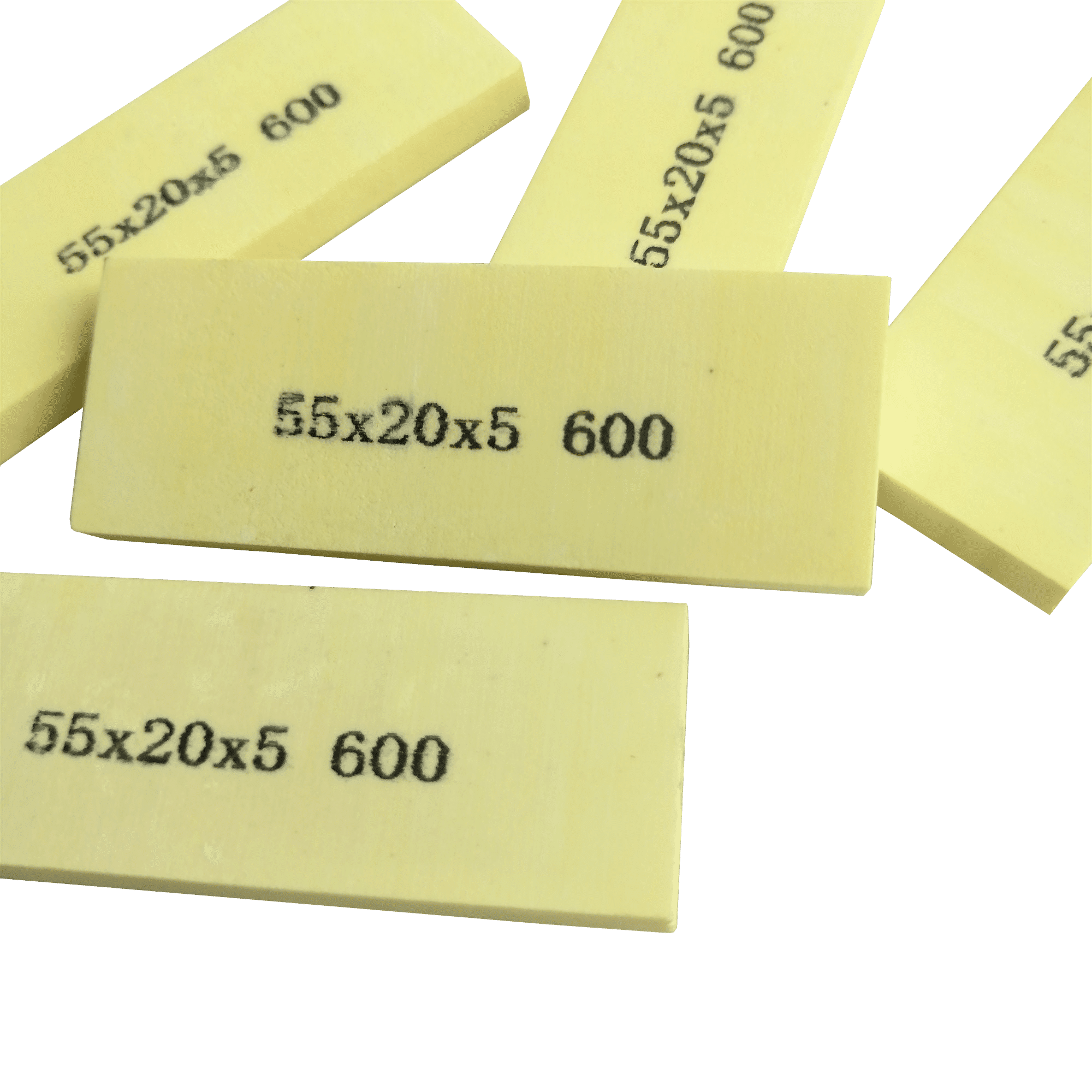

- Shape Rectangular, Square, Custom Profiles

- Hardness Soft to Medium

- Backing Flexible cloth or paper-based backing

- Chemical Composition Al2O3, SiC, bonding agents

- Bonding Vitrified & Resin Bonded

- Grain Type Fine and Extra Fine

- Toughness High resistance to fracture

- Click to View more

X

Superfinishing Grinding Stones Price And Quantity

- 0.5 USD ($)/Piece

- 300 Piece

- Roll, strip, or cut shapes

- Superfinishing and microfinishing of precision parts

- Dark grey, brown, or green (varies by material)

- Ra 0.05 - 0.2 m

- Cool, dry place, avoid moisture and direct sunlight

- Automotive, bearing, hydraulic, and aerospace industries

- Highly durable for extended operational cycles

- Max 30 m/s

- Suitable for steel, cast iron, and non-ferrous metals

- Up to 350C

Superfinishing Grinding Stones Product Specifications

- Superfinishing Grinding Stone

- Aluminum Oxide / Silicon Carbide

- Soft to Medium

- Flexible cloth or paper-based backing

- Al2O3, SiC, bonding agents

- 5mm to 25mm width options

- Fine and Extra Fine

- High resistance to fracture

- 80 to 2000 grit

- 10mm x 50m

- Vitrified & Resin Bonded

- Rectangular, Square, Custom Profiles

- Roll, strip, or cut shapes

- Superfinishing and microfinishing of precision parts

- Dark grey, brown, or green (varies by material)

- Ra 0.05 - 0.2 m

- Cool, dry place, avoid moisture and direct sunlight

- Automotive, bearing, hydraulic, and aerospace industries

- Highly durable for extended operational cycles

- Max 30 m/s

- Suitable for steel, cast iron, and non-ferrous metals

- Up to 350C

Product Description

Find triumphant surface perfection with our hot-selling Superfinishing Grinding Stones, available in rarefied dark grey, brown, or green hues to match specific materials. Order today and elevate your process with decorated technology engineered for microfinishing and superfinishing of precision parts in automotive, aerospace, bearing, and hydraulic industries. These stones, compatible with steel, cast iron, and non-ferrous metals, achieve a mirror-like surface finish (Ra 0.05-0.2 m) and endure up to 350C. Choose from roll, strip, or custom-cut forms-with exceptional wear resistance, fine to extra fine grain, and flexible backings-meeting global standards in quality and reliability from a trusted China-based distributor.

Triumphant Superfinishing for Precision Applications

Superfinishing Grinding Stones present decorated features such as highly durable rolls, strips, and shapes, customizable to machine dynamics. They employ fine and extra fine grains, utilizing advanced vitrified and resin bonding for stable, consistent performance. Application involves securing selected stones to precision equipment, running at up to 30 m/s, to achieve incredible finishes (Ra 0.05-0.2 m). Designed specifically for extended cycles, they offer high resistance to fracture for top-tier results in every project.

Market Value and Seamless Transportation

Our Superfinishing Grinding Stones command growing market value in China and beyond, serving domestic and international demand. Fast and reliable transportation ensures timely and secure delivery, typically within the quoted delivery timeframes. Flexible payment terms facilitate smooth transactions and quoting, solidifying trust between supplier and customer. Dedicated to client satisfaction, we offer comprehensive support from quotation to post-sale services, meeting dynamic industrial requirements with each order.

Triumphant Superfinishing for Precision Applications

Superfinishing Grinding Stones present decorated features such as highly durable rolls, strips, and shapes, customizable to machine dynamics. They employ fine and extra fine grains, utilizing advanced vitrified and resin bonding for stable, consistent performance. Application involves securing selected stones to precision equipment, running at up to 30 m/s, to achieve incredible finishes (Ra 0.05-0.2 m). Designed specifically for extended cycles, they offer high resistance to fracture for top-tier results in every project.

Market Value and Seamless Transportation

Our Superfinishing Grinding Stones command growing market value in China and beyond, serving domestic and international demand. Fast and reliable transportation ensures timely and secure delivery, typically within the quoted delivery timeframes. Flexible payment terms facilitate smooth transactions and quoting, solidifying trust between supplier and customer. Dedicated to client satisfaction, we offer comprehensive support from quotation to post-sale services, meeting dynamic industrial requirements with each order.

FAQ's of Superfinishing Grinding Stones:

Q: How do Superfinishing Grinding Stones enhance surface finish quality?

A: These stones are engineered to deliver ultra-fine finishes (Ra 0.05-0.2 m), removing micro-level imperfections efficiently, resulting in smoother surfaces on precision parts.Q: What is the recommended storage condition for these stones?

A: Store the stones in a cool, dry place, away from moisture and direct sunlight to maintain their integrity and performance over time.Q: Where can Superfinishing Grinding Stones be applied?

A: They are suitable for automotive, bearing, hydraulic, and aerospace industries, proving ideal for finishing steel, cast iron, and non-ferrous components.Q: What grain sizes are available for the stones and how does it impact the process?

A: Offered from 80 to 2000 grit, the range allows users to select from coarse for rapid material removal to extra fine for microfinishing, enabling flexible process control.Q: How is the delivery handled after an order is placed?

A: Orders are processed promptly, with secure packaging and efficient transportation to ensure the grinding stones arrive safely within the agreed delivery timeframe.Q: What is the benefit of choosing vitrified or resin bonded stones?

A: Vitrified and resin bonded options provide tailored hardness, wear resistance, and stability, ensuring longevity and optimal results for specific superfinishing applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese