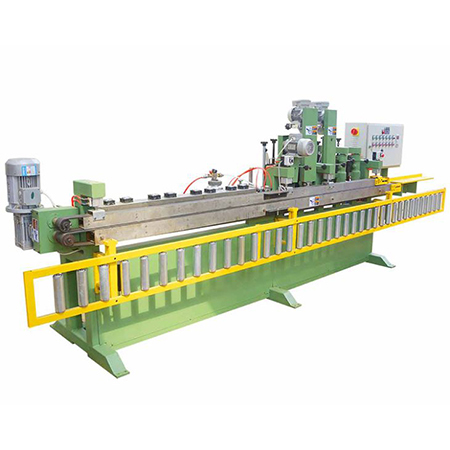

Sanding Belt Skiving Machine

5000-7000 USD ($)/Set

Product Details:

- Bonding Suitable for various bonded abrasives

- Hardness Hardened tool parts, robust frame

- Backing Paper, Cloth, Polyester (up to 330mm width)

- Shape Rectangular belt strips

- Grain Type Aluminum oxide, Zirconia, Silicon Carbide compatible

- Chemical Composition Industrial-grade MS body, tungsten carbide coated blades

- Toughness Heavy duty, corrosion resistant build

- Click to View more

X

Sanding Belt Skiving Machine Price And Quantity

- 0.15 - 7000.00 USD ($)/Set

- 1 Set

- 5000-7000 USD ($)/Set

Sanding Belt Skiving Machine Product Specifications

- Aluminum oxide, Zirconia, Silicon Carbide compatible

- Rectangular belt strips

- Up to 330mm width

- 5mm to 330mm width, customizable length

- Automatic Sanding Belt Skiving Machine

- Paper, Cloth, Polyester (up to 330mm width)

- Heavy duty, corrosion resistant build

- Hardened tool parts, robust frame

- Mild Steel body, tungsten carbide trimming tool

- 16 to 400 Grit applicable

- Industrial-grade MS body, tungsten carbide coated blades

- Suitable for various bonded abrasives

Sanding Belt Skiving Machine Trade Information

- 1000 Set Per Month

- 30 Days

Product Description

To become a top organization in this domain, we have been engaged in offering premium grade Sanding Belt Skiving Machine. This machine is highly admired among clients due to its robust construction, high strength, and corrosion resistant surface. Provided machine is mainly used for cutting material off in slices, usually metal. This machine is made using top-notch grade components by our adroit professionals with the latest innovative techniques. In addition to this, offered Sanding Belt Skiving Machine can be bought from us in different specifications as per clients demand. Additionally, this machine is known for its fast processing speed.

Technical Specification

- Skiving belt width: unlimited

- Skiving variable speed: 30-200mm/s

- Automatic operation and continuous feed

- Dust catcher: 1

- Skiving mode: diamond wheel, abrasive belts, steel brush

- Locking roll: pneumatic

- Installed power: 7.5 KW

- Pneumatic Pressure: 0.7 Mpa

- Overall machine dimensions: 2.9x0.7x1.6m(LxWxH)

- Approx. weight: 1600kg

High-Performance Skiving Technology

Built for heavy-duty industrial use, the machine features a geared motor with speed control and a tungsten carbide blade for precise, long-lasting trimming performance. It accommodates a wide range of abrasive grain sizes, ensuring adaptability for different production needs. The PLC-based control system simplifies operation while enhancing accuracy and repeatability.

Versatile Application and Customization

Suitable for skiving abrasive belt strips with customizable widths (5mm to 330mm) and lengths, this unit is compatible with aluminum oxide, zirconia, and silicon carbide grains. Its robust construction and corrosion-resistant materials make it ideal for continuous, high-volume usage in various manufacturing settings.

Safety and Ease of Use

Operator safety is ensured with protective guarding and an emergency stop system. The semi-automatic operation streamlines the workflow, reducing manual intervention and increasing productivity while maintaining consistent skiving quality across batches.

FAQs of Sanding Belt Skiving Machine:

Q: How does the sanding belt skiving machine ensure precise edge trimming?

A: This machine employs a tungsten carbide blade driven by a geared motor, paired with a PLC-based control system. Adjustable speed settings (28 m/min) and precision construction enable exact edge trimming and skiving to the desired thickness (0.52 mm), consistently meeting production standards.Q: What types of abrasive materials and backing can the machine process?

A: The machine is compatible with abrasive grains such as aluminum oxide, zirconia, and silicon carbide. It can handle belts with backing materials including paper, cloth, and polyesterup to 330 mm in widthmaking it suitable for various bonded abrasive configurations.Q: When should I consider using this skiving machine in my production process?

A: Utilize this machine when you require high-accuracy skiving or edge trimming of abrasive belts, especially for large-scale or continuous production. It is particularly beneficial for manufacturers who need precise, consistent belt joints and edge quality.Q: Where can this machine be installed, and who can benefit from it?

A: Designed for industrial environments, the machine is best suited for abrasive belt manufacturing units, tool supply companies, and workshops handling flexible abrasives. Distributors, exporters, and manufacturers in China and other regions can benefit from this equipment.Q: What is the step-by-step process for operating the machine?

A: First, set the desired skiving width and thickness via the control panel. Load the abrasive belt strip (up to 330mm wide), select the appropriate speed, and activate the machine. The PLC system will automate the skiving, and finished strips can be collected once the process is complete. The emergency stop ensures operator safety if needed.Q: How does the semi-automatic operation and PLC control improve usage?

A: Semi-automatic operation minimizes manual handling and reduces error, while the PLC-based control system allows for programmable settings, faster adjustments, and enhanced repeatability for batch processing. This leads to increased productivity and consistent results.Q: What are the main advantages of using this skiving machine?

A: The key benefits include robust construction for heavy-duty tasks, precise skiving for various abrasive materials and backings, enhanced safety with guarded mechanisms, and significant productivity improvement due to automation. Customizable size support and versatility across abrasive types further add to its value.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese