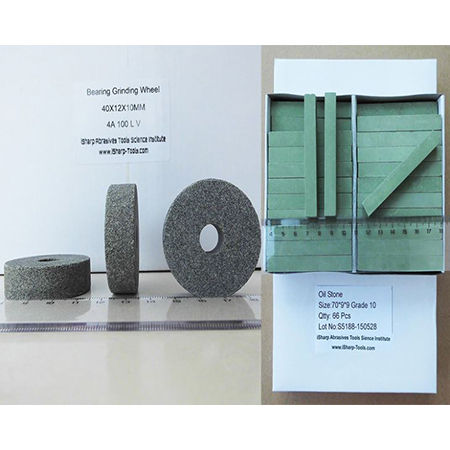

Polishing Wheel

Product Details:

- Toughness High toughness for durability

- Backing Fabric/Cotton backing

- Hardness Medium, Soft, Hard

- Chemical Composition Cotton/Wool/Felt base with abrasives

- Shape Round

- Grain Type Aluminum Oxide, Silicon Carbide

- Bonding Resin Bonded / Sawtooth Stitching

- Click to View more

Polishing Wheel Price And Quantity

- 5000-7000 USD ($)/Set

- 0.15 - 7000.00 USD ($)/Set

- 1 Set

- Available on request

- 1/2, 1, 2 inches

- Box/Packed in quantity as per order

- Buffing, Surface finishing, Gloss enhancement

- Metal, Stainless Steel, Jewelry, Automotive, Glass, Marble Polishing

- Available as per requirement

- 6 to 16 inches

- 2800 - 3600 RPM

- White, Yellow, Red

Polishing Wheel Product Specifications

- 25 mm, 50 mm, 75 mm, 100 mm

- High toughness for durability

- Fabric/Cotton backing

- Round

- Aluminum Oxide, Silicon Carbide

- Medium, Soft, Hard

- Cotton/Wool/Felt base with abrasives

- Resin Bonded / Sawtooth Stitching

- Surface Polishing Wheel

- P60 to P400

- 200 mm, 250 mm, 300 mm, 350 mm, 400 mm

- Cotton Cloth / Wool / Felt

- Available on request

- 1/2, 1, 2 inches

- Box/Packed in quantity as per order

- Buffing, Surface finishing, Gloss enhancement

- Metal, Stainless Steel, Jewelry, Automotive, Glass, Marble Polishing

- Available as per requirement

- 6 to 16 inches

- 2800 - 3600 RPM

- White, Yellow, Red

Polishing Wheel Trade Information

- 1000 Set Per Month

- 30 Days

Product Description

With an aim to be a market leader in our domain, we are becoming reputed manufacturer and supplier of supreme grade Polishing Wheel, which is mainly used for smoothing a work pieces surface using an abrasive and a work wheel. Offered wheel is made using top-notch quality material under guidance of our deft professionals with innovative techniques. Provided wheel is safely packed to prevent damage during transit. This wheel is safely packed to prevent damage during transit. In addition to this, offered Polishing Wheel finds its usefulness in metalworking, steel and manufacturing industries.

Technical Specification

| Diameter : | 100mm~900mm |

| Abrasive texture: | Alumina, silicon carbide and cerium oxide |

| Abrasive grain: | F240 ~F2000 |

| External diameter: | 125mm, 150mm, 200mm |

| Abrasive grain: | F240~F1200 |

| Diameter : | 100mm~300mm |

| Abrasive texture: | silicon carbide and cerium oxide |

| Abrasive grain: | F240~F1200 |

| Diameter : | 300mm x 100mm x 127mm |

| Abrasive texture: | White corundum and single crystal corundum |

| Abrasive grain: | F240~F1200 |

Superior Performance and Customization

Our surface polishing wheels are designed for both professional and industrial use. Their high-quality cotton, wool, or felt materials ensure excellent durability and consistent results, no matter the substrate. With a range of grain sizes and customizable mounting holes and dimensions, each wheel is tailored to optimize your buffing and finishing processes, enhancing both efficiency and shine.

Versatile Applications Across Industries

Suitable for metals, stainless steel, jewelry, automotive detailing, glass, and marble, these polishing wheels support a broad spectrum of polishing and finishing operations. Whether you need to remove minor imperfections or achieve a mirror finish, our wheels adapt seamlessly to your requirements, making them an ideal choice for manufacturers, workshops, and artisans.

FAQs of Polishing Wheel:

Q: How do I select the correct polishing wheel for my specific application?

A: Choosing the right polishing wheel depends on the material you are working with and the desired finish. For metals and stainless steel, consider harder wheels and finer grains (P320P400). For delicate surfaces like glass or jewelry, softer wheels and a medium grain size are advisable. Our team can assist with tailored recommendations.Q: What benefits does using a cotton/wool/felt based polishing wheel provide?

A: Polishing wheels made with cotton, wool, or felt deliver superior surface smoothness, excellent shine, and consistent abrasion. Their structure allows for better heat dissipation and surface adaptation, minimizing the risk of burns or scratches during high-speed polishing.Q: Where can these polishing wheels be used?

A: These polishing wheels are ideal for workshops, manufacturing facilities, jewelry studios, automotive repair shops, and glass/marble polishing centers. Their versatile design accommodates a broad range of surface finishing and buffing tasks.Q: What is the process for customizing wheel size or mounting holes?

A: Custom sizes and mounting holes can be requested at the time of order. Simply specify your requirements such as outer diameter, thickness, hole diameter, and preferred material; our production team will manufacture the wheels accordingly.Q: When should I replace my polishing wheel?

A: Replace your polishing wheel when it begins to show signs of excessive wear, loss of abrasive efficiency, or reduced surface finish quality. Regular inspection ensures optimal results and workplace safety.Q: How can I maximize the lifespan and effectiveness of my polishing wheel?

A: To extend the life of your wheel, operate within the recommended speed (28003600 RPM), avoid excessive pressure, store wheels in a dry environment, and use appropriate grain sizes and hardness for your application.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese