Isharp Superfinishing Stone

50 INR/Piece

Product Details:

- Bonding Vitrified or Resin Bond

- Chemical Composition AlO or SiC with specified binding agents

- Toughness High

- Hardness Medium to Hard

- Backing None (Solid Stone)

- Grain Type Microcrystalline or conventional

- Shape Rectangular, Square, or Custom

- Click to View more

X

Isharp Superfinishing Stone Price And Quantity

- 50 INR/Piece

- 500 Number

- Up to 3000 RPM

- White, Green, or Grey depending on abrasive type

- Box or Custom packaging as required

- Withstands high operational temperatures

- Up to Ra 0.02 m

- Works with most superfinishing machines and holders

- Superfinishing and microfinishing of metal components

- Cylindrical, Flat, or Special Surface Finishing

Isharp Superfinishing Stone Product Specifications

- Medium to Hard

- AlO or SiC with specified binding agents

- High

- 80 to 1200 Grit

- Vitrified or Resin Bond

- According to application requirements

- Rectangular, Square, or Custom

- None (Solid Stone)

- Custom as per users need

- Abrasive Grain (Aluminium Oxide, Silicon Carbide options)

- Microcrystalline or conventional

- Superfinishing Stone

- Up to 3000 RPM

- White, Green, or Grey depending on abrasive type

- Box or Custom packaging as required

- Withstands high operational temperatures

- Up to Ra 0.02 m

- Works with most superfinishing machines and holders

- Superfinishing and microfinishing of metal components

- Cylindrical, Flat, or Special Surface Finishing

Product Description

Product Description

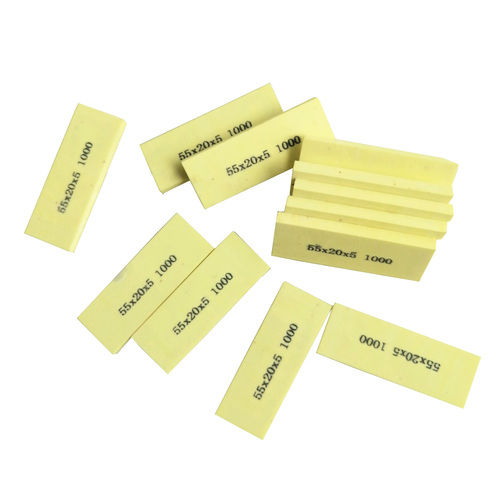

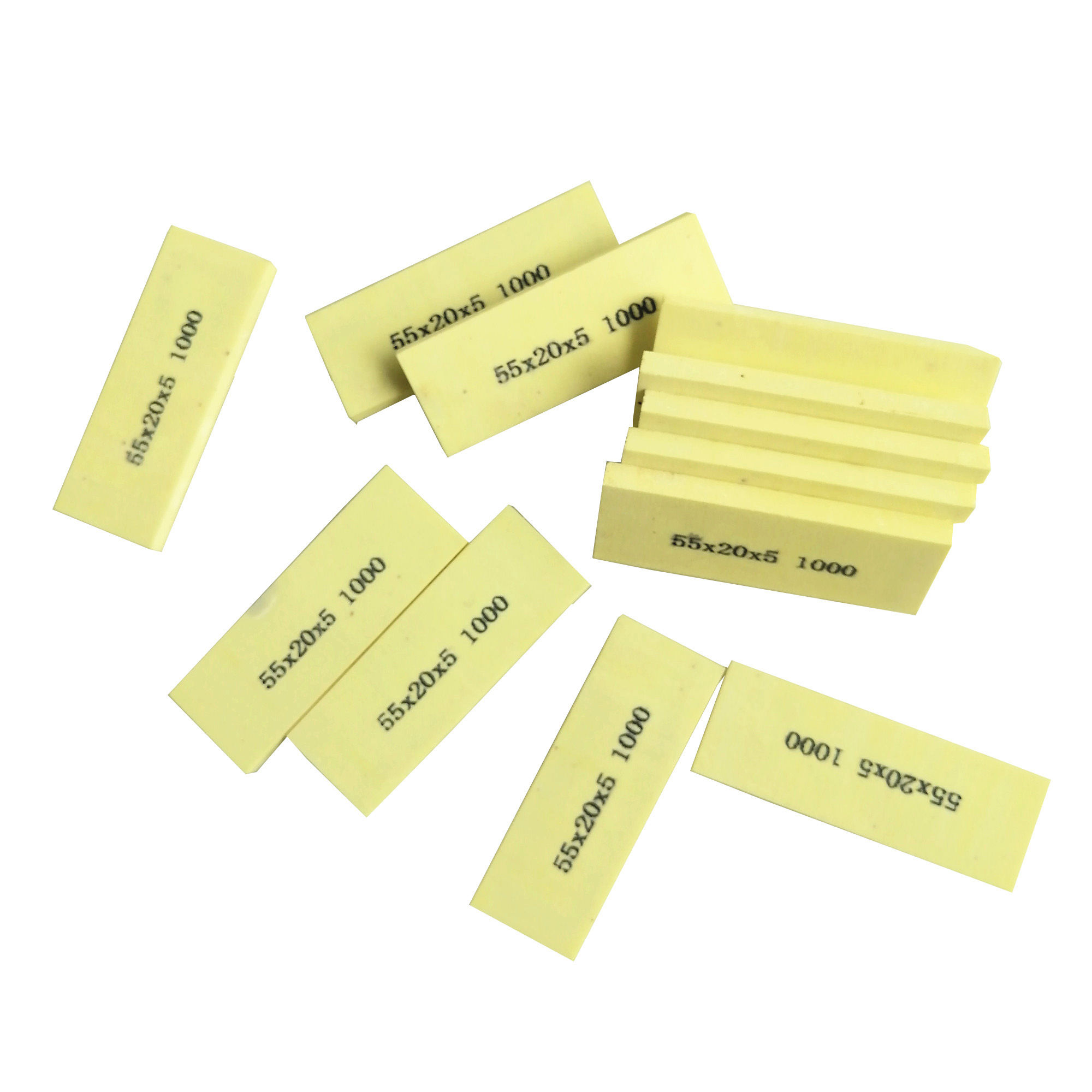

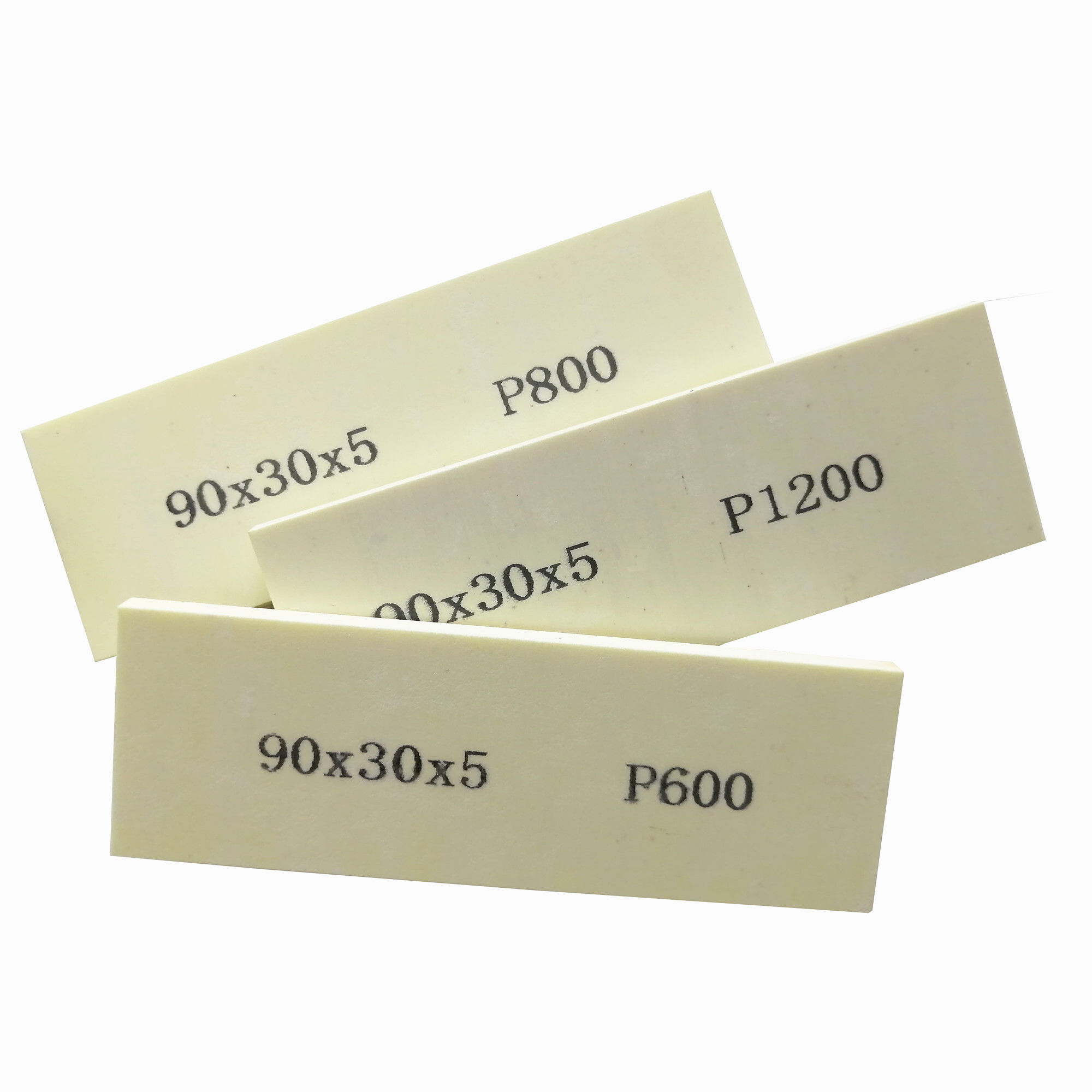

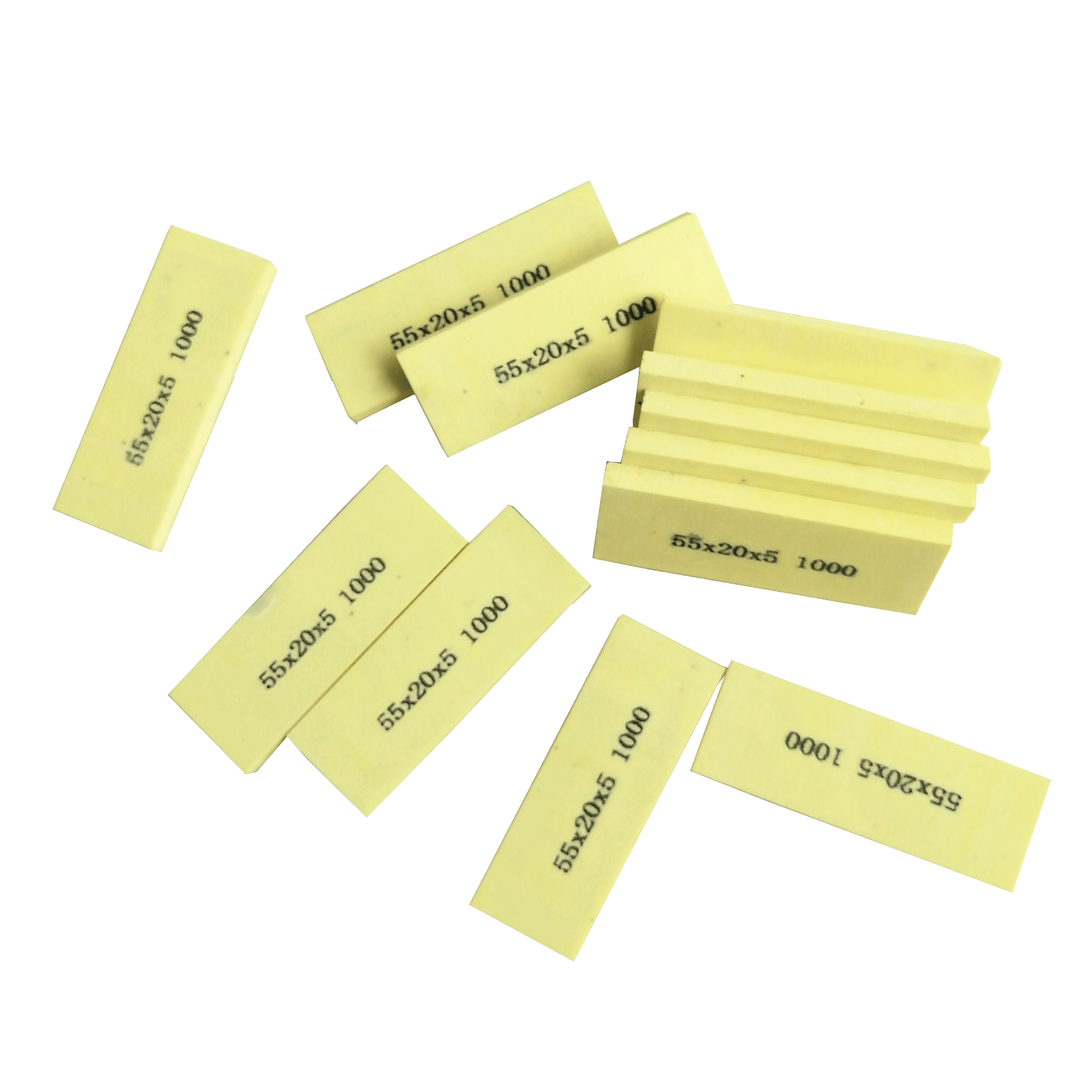

Superfinishing stone Honing Stones for Mold and Automotive Bearing

Product Description

Brief introduction of Mold Polishing Stones Automotive Bearing Honing Stones

High durability for the super fine honing stones good roughness quality of the workpieceWidely used for grinding stock absorber piston rod bearing and so on in various industry There are many polishing process and quality for your choice

Features of Mold Polishing Stones Automotive Bearing Honing Stones

1 Free sample for general sharpening stone uniform quality as first sample offered

2 Sharpening dressing stone of various sizes shapes grits and applications are available

3 Factory direct best price and shortest lead time for general sharpening stone

4 Production since 1958 61years manufacturing experience will give you best sharpening stone solution

Isharp Superfinishing Stone Honing Stones for Fine Finishing

Product Parameters

Super Finishing Honing Stone

Length 5070mmcan be customized

Width 615mmcan be customized

Thickness 615mmcan be customized

Grit 4006000can be customized

Detailed Photos

Isharp Superfinishing Stone Honing Stones for Fine FinishingIsharp Superfinishing Stone Honing Stones for Fine FinishingIsharp Superfinishing Stone Honing Stones for Fine Finishing

Isharp Superfinishing Stone Honing Stones for Fine Finishing

The mold polishing stones automotive bearing honing stones are packed in white paper first then in cartons wooden casesIn each step the mold polishing stones and automotive bearing honing stones are packed well to ensure safe arrival

Besides that sea insurance will be applied for you as once more protection With monthly capacity of 100000pcs superfinishing mold polishing stones automotive bearing honing stones shipping time will be kept without any delay

Related Products

Isharp Superfinishing Stone Honing Stones for Fine Finishing

Isharp Superfinishing Stone Honing Stones for Fine Finishing

Isharp Superfinishing Stone Honing Stones for Fine Finishing

Super Finishing Honing Stone Automotive Bearing polishing Stones Honing Sticks Abrasive Polishing Finishing Stones

Isharp Superfinishing Stone Honing Stones for Fine Finishing

Isharp Superfinishing Stone Honing Stones for Fine Finishing

Isharp Superfinishing Stone Honing Stones for Fine Finishing

Dressing Stick for Diamond Grinding Wheel Vitrified Bond Honing Stone Sulphur Sharpening Stone

Contact information

Any questions please contact us

Nancy Lu iSharp Abrasives Tools Science Institute

Add A2507 Kaixuanmen Tongbai S RdZhengzhou Henan 450006 China

Exceptional Surface Quality

Isharp Superfinishing Stones are designed to provide remarkable smoothness on metal parts, meeting stringent surface finish requirements. Achieving finishes up to Ra 0.02 m, they are the preferred choice in industries demanding heightened precision and superior component quality. Their adaptability ensures flawless performance on a variety of surfaces.

Versatile Application & Compatibility

These finishing stones come in various sizes and shapes, perfect for cylindrical, flat, or custom surfaces. With granular options from 80 to 1200 grit, the stones accommodate wide-ranging applications. They integrate seamlessly with standard superfinishing machines, making them a versatile solution for manufacturers, suppliers, and traders alike.

Durability and Heat Resistance

Constructed from high-toughness microcrystalline or conventional grains, Isharp Superfinishing Stones can endure demanding conditions. The vitrified or resin bonds ensure long-lasting use, and the stones can operate under high speeds and elevated temperatures without compromising finish quality. Custom packaging further enhances convenience and protection.

FAQ's of Isharp Superfinishing Stone:

Q: How does the Isharp Superfinishing Stone improve the surface finish of metal components?

A: The Isharp Superfinishing Stone utilizes high-grade abrasive grains, available in a range of grit sizes, to meticulously remove surface irregularities. This results in ultra-smooth finishes-achieving surface roughness values as low as Ra 0.02 m-making your components ideal for applications that demand superior surface quality.Q: What types of surfaces and shapes can the Isharp Stone be used on?

A: This superfinishing stone is engineered for versatility and can be effectively used on cylindrical, flat, or custom-contoured metal surfaces. The stone comes in rectangular, square, or custom shapes and sizes to precisely match various application requirements.Q: When should different abrasive colors or types be selected?

A: The stone's color (White, Green, or Grey) corresponds to its abrasive makeup. White typically represents Aluminium Oxide, Green or Grey denote Silicon Carbide. Choose the abrasive based on the material of your workpiece and the desired finish-Aluminium Oxide for ferrous metals, Silicon Carbide for non-ferrous or harder surfaces.Q: Where can Isharp Superfinishing Stones be integrated within a production line?

A: These stones can be installed in most common superfinishing machines and holders found in manufacturing facilities. Their compatibility ensures they are suitable for use across various industries, whether in standalone processes or as part of a comprehensive finishing system.Q: What is the process for selecting the right grit size and bonding for my application?

A: Begin by evaluating the initial roughness of your workpiece and the required surface result. Coarser grits (80-400) are chosen for faster material removal, while finer grits (600-1200) deliver higher polish. Vitrified bonds are recommended for durability and high-load machining, while resin bonds offer better shock absorption for delicate finishes.Q: How do Isharp Stones benefit everyday industrial finishing operations?

A: Beyond delivering exceptional finishes, Isharp Stones are highly durable, resist wear even at high speeds or temperatures, and adapt to diverse machine setups. This efficiency reduces downtime, increases productivity, and lowers the cost per component over time.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese