Dressing Sticks for Diamond Grinding Wheel

50 INR/Piece

Product Details:

- Grain Type Monocrystalline

- Shape Rectangular

- Chemical Composition Al2O3 (Aluminium Oxide)

- Hardness Medium to Hard

- Toughness High

- Bonding Vitrified Bond

- Material Aluminium Oxide

- Click to View more

X

Dressing Sticks for Diamond Grinding Wheel Price And Quantity

- 3000 Piece

- 50 INR/Piece

- For trueing, dressing, and cleaning diamond grinding wheels

- White / Pink

- 3.95 g/cm³

- Up to 1,500°C

- Boxed

- Conforms to international abrasive standards

- Suitable for all diamond and CBN wheels

- Excellent

- Manual use; suitable for wet and dry dressing operations

- Smooth

Dressing Sticks for Diamond Grinding Wheel Product Specifications

- Medium to Hard

- Vitrified Bond

- Aluminium Oxide

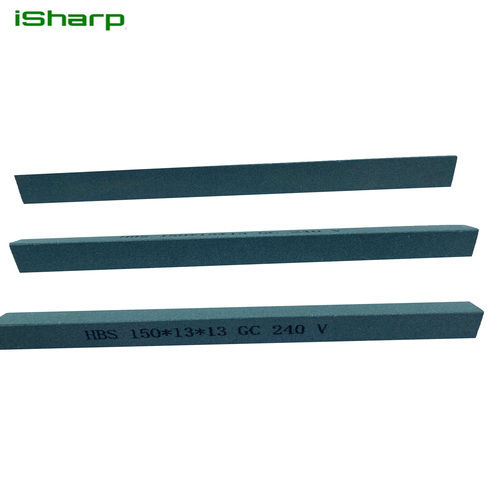

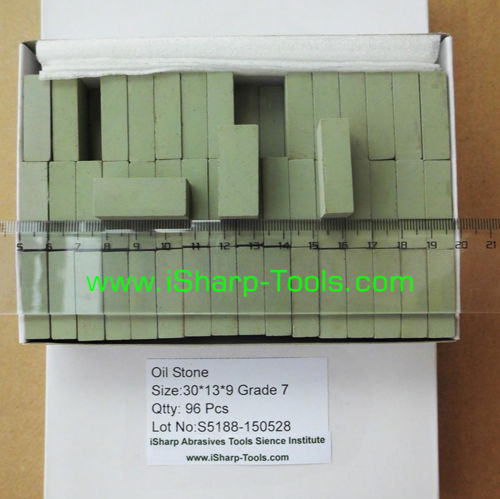

- 150 mm x 25 mm x 25 mm

- 75 mm x 10 mm x 10 mm

- Monocrystalline

- High

- Rectangular

- Al2O3 (Aluminium Oxide)

- Fine (180 Grit) / Medium (120 Grit) / Coarse (80 Grit)

- Dressing Stick

- For trueing, dressing, and cleaning diamond grinding wheels

- White / Pink

- 3.95 g/cm³

- Up to 1,500°C

- Boxed

- Conforms to international abrasive standards

- Suitable for all diamond and CBN wheels

- Excellent

- Manual use; suitable for wet and dry dressing operations

- Smooth

Product Description

Product Name Dressing Sticks for Diamond grinding wheel

Origin Zhengzhou China

Brand iSharp

Type Aluminium Oxide Grinding Stone

Material White Corundum

The dressing Sticks for diamond grinding wheel are especially for truing diamond grinding wheel in glass industry to expose new diamonds to maintain the sharpness for glass edge processing Different sizes grit hardness and so on can be made as your request The precision can be reached to Thicness015015mm Width02 05mm and Length051mm

Company Profile

iSharp Abrasives Tools Science Institute Is a leading grinding solutions provides from 1991 We have been in this abrasive filed more than 20 years We put a lot of time and energy into creasing tailored abrasive solutions to meet your needs and exceed your expectationsOur products include the cutting disc production line coated abrasive belt conversion line flap disc production line and mounted flap wheel production line Expect these we also have different products such as the cutting disc flap disc oil stone and grinding wheel

Our products has exported to many countries such as Russia America Germany Italy Ukraine Singapore Brail Mexico Poland And so on Besides we also have built business relationship with some famous company in this field such as Klingspor Deerfos Sunmight CGW and so on Having been innovating the cutting disc and grinding wheel industry for over 15 years you can count on our products to perform consistently

FAQ

1 who are weWe are based in Henan China start from 2013sell to Domestic Market2000Western Europe1300Mid East1000Eastern Europe1000North America900South Asia700Southeast Asia600Southern Europe500Central America500Oceania500Africa500South America300Eastern Asia200 There are total about 301500 people in our office2 how can we guarantee qualityAlways a preproduction sample before mass productionAlways final Inspection before shipment3what can you buy from usgrinding wheel making machineflap disc machinecoated abrasive machineryabrasive toolscutting discs4 why should you buy from us not from other suppliersExperienced abrasives engineers constitute a research team from 1991 Adhering to the Green Efficiency Precision concept we design develop and produce suitable abrasive products provide a complete grinding technology services5 what services can we provideAccepted Delivery Terms FOBCFRCIFCPTExpress DeliveryAccepted Payment CurrencyUSDEURJPYCADAUDHKDGBPCNYCHFAccepted Payment Type TTLCDP DAWestern UnionCashLanguage SpokenEnglishChinese

Versatile Dressing for All Diamond and CBN Wheels

These aluminium oxide dressing sticks are engineered to efficiently true, dress, and clean all types of diamond and CBN grinding wheels. With superior toughness and hardness, they ensure optimal restoration and cleaning of your wheels' grit surfaces, prolonging tool life and maintaining high-precision operations. Their compatibility spans across multiple wheel types and applications, making them a versatile choice for manufacturers, traders, and exporters in China and beyond.

Outstanding Wear Resistance and Heat Tolerance

A unique vitrified bond structure combined with high-density monocrystalline grain provides exceptional wear resistance and thermal stability. With a temperature tolerance up to 1,500C, these dressing sticks consistently deliver smooth finishes under challenging working conditions, whether used in wet or dry dressing processes.

FAQ's of Dressing Sticks for Diamond Grinding Wheel:

Q: How do I properly use a dressing stick for diamond grinding wheels?

A: To use a dressing stick, gently apply it manually to the rotating surface of your diamond or CBN wheel. Use steady, even pressure and move the stick across the wheel's face to true, clean, or dress the wheel. The process can be performed in both wet and dry conditions to remove debris and restore wheel sharpness.Q: What are the main benefits of using these dressing sticks?

A: These dressing sticks offer excellent wear resistance, high toughness, and the ability to function at temperatures up to 1,500C. They help maintain the efficiency and accuracy of diamond and CBN grinding wheels by ensuring a smooth, clean, and refreshed abrasive surface.Q: When should I dress my diamond or CBN grinding wheel?

A: Dressing is recommended when you notice a decline in grinding performance, uneven surfaces, or wheel loading. Regular dressing optimizes cutting action and extends wheel life, ensuring consistent results for high-precision applications.Q: What grit sizes are available, and how should I choose between them?

A: Dressing sticks are available in fine (180 grit), medium (120 grit), and coarse (80 grit) options. Select a finer grit for lightly loaded wheels and achieving a smooth finish, or a coarser grit for heavier cleaning or more aggressive dressing requirements.Q: Are these dressing sticks suitable for both wet and dry operations?

A: Yes, the vitrified bond and high-quality aluminium oxide composition ensure that these sticks perform effectively in both wet and dry dressing applications, providing flexibility in various working environments.Q: Where can I source these dressing sticks?

A: As a manufacturer, exporter, distributor, supplier, and trader in China, we offer these dressing sticks globally. Packaged in boxed formats, they are available in standard sizes for both rolls and strips to suit different operational needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese