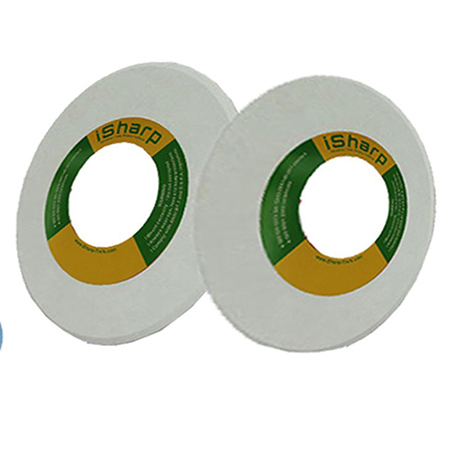

Thread Grinding Wheel

Product Details:

- Grain Type Abrasive Grain

- Bonding Vitrified Bond

- Hardness Medium to Hard

- Toughness High

- Shape Plain, Profiled (as per thread)

- Chemical Composition Al2O3 / SiC based with vitrified components

- Backing N/A (Solid wheel)

- Click to View more

Thread Grinding Wheel Price And Quantity

- 1 Set

- 5000-7000 USD ($)/Set

- 0.15 - 7000.00 USD ($)/Set

Thread Grinding Wheel Product Specifications

- N/A (Solid wheel)

- Thread Grinding Wheel

- Al2O3 / SiC based with vitrified components

- Varies based on thread type

- Plain, Profiled (as per thread)

- Customizable as per requirement

- High

- Medium to Hard

- Fine, Medium, Coarse (typically 46 to 220 grit)

- Vitrified Bond

- Aluminum Oxide / Silicon Carbide

- Abrasive Grain

Thread Grinding Wheel Trade Information

- 1000 Set Per Month

- 30 Days

Product Description

We are one of famous firms in this domain, indulged in manufacturing and supplying supreme grade Thread Grinding Wheel, which is well suited to be used to grind material in hassle free manner. Offered wheel is highly admired among client owing to its robust construction and less maintenance. Provided wheel is used to be installed in thread cutting tools. This wheel is perfect to be used for grinding tough and very hard steels. In addition to this, offered Thread Grinding Wheel is checked on various parameters for ensuring defect free delivery to clients. Moreover, this wheel has user-friendly design and longer life.

Technical Specification

| D | H | T | Bond |

| 350 | 8 | 160 | Vitrified |

| 350 | 10 | 160 | |

| 400 | 8 | 203 | |

| 400 | 10 | 203 | |

| 400 | 13 | 203 | |

| 400 | 32 | 203 | |

| 450 | 20 | 229 | |

| 450 | 25 | 229 | |

| 500 | 10 | 305 |

High-Precision Thread and Gear Grinding

Engineered for demanding thread and gear grinding, these wheels offer superior accuracy, supporting a surface finish of up to Ra 0.2 m. With options compatible with a wide range of machines, and customizable sizes, they serve both CNC and conventional systems, fulfilling varied industrial requirements. Their robust construction ensures consistency in high-precision environments.

Versatility Across Applications and Machines

With a broad diameter (100800 mm) and width range (10300 mm), these thread grinding wheels address diverse project sizes and geometries. Their compatibility with both CNC and manual grinders, alongside customizable roll and mounting specifications, ensures a seamless fit within unique manufacturing configurations.

Durability and Material Quality

Manufactured from high-quality Aluminum Oxide or Silicon Carbide grains and vitrified bonds, these wheels provide both toughness and longevity. They withstand rigorous grinding conditions at operating speeds up to 35 m/s, maintaining their integrity, profile, and efficient cutting capability through repeated use.

FAQs of Thread Grinding Wheel:

Q: How are the thread grinding wheels customized for different machines?

A: The wheels are available in various diameters and widths, with mounting hole sizes tailor-made to your specific machine spindle. This ensures a precise fit for both CNC and conventional thread grinding machines.Q: What materials and bonding are used in these grinding wheels?

A: These wheels are made from Aluminum Oxide or Silicon Carbide abrasive grains, bonded with vitrified components. This combination offers high toughness, consistent performance, and durability in precision grinding operations.Q: When should I opt for a fine or coarse grain size?

A: Fine grain sizes (such as 220 grit) are suitable for achieving ultra-fine surface finishes and detailed profiles, while coarse grains (around 46 grit) are ideal for rapid material removal during initial grinding stages or when tolerances are less stringent.Q: Where can these thread grinding wheels be used?

A: They are suitable for high-precision thread and gear grinding in industries such as automotive, aerospace, and manufacturing, where both CNC and manually operated grinding machines are employed.Q: What is the recommended process for coolant selection during grinding?

A: Choose an oil- or water-based coolant depending on the specific grinding application and material being processed. Proper coolant selection enhances surface quality, controls heat buildup, and prolongs wheel life.Q: What are the key benefits of using these thread grinding wheels?

A: Key benefits include customizable sizing, compatibility with various machines, high toughness, excellent surface finish up to Ra 0.2 m, and the ability to withstand high-speed operations while maintaining profile accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese