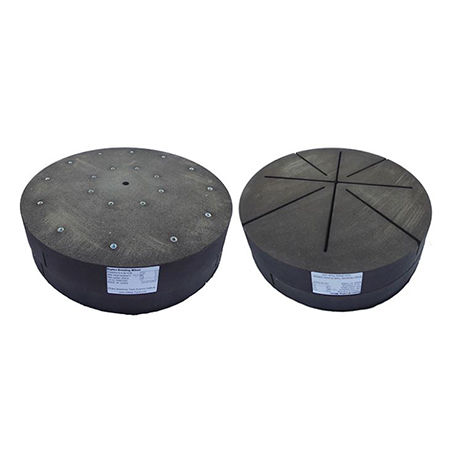

Straight Grinder Wheels

Product Details:

- Toughness High

- Chemical Composition Al2O3 (Aluminum Oxide), SiC (Silicon Carbide)

- Hardness Medium, Hard

- Bonding Vitrified, Resin Bond

- Shape Straight

- Grain Type White, Brown

- Material Aluminum Oxide, Silicon Carbide

- Click to View more

Straight Grinder Wheels Price And Quantity

- 5000-7000 USD ($)/Set

- 1 Set

- 0.15 - 7000.00 USD ($)/Set

Straight Grinder Wheels Product Specifications

- 25 mm, 50 mm

- Al2O3 (Aluminum Oxide), SiC (Silicon Carbide)

- 100 mm, 150 mm, 200 mm

- Aluminum Oxide, Silicon Carbide

- Straight

- Vitrified, Resin Bond

- High

- Medium, Hard

- 36, 46, 60, 80 Grit

- White, Brown

- Bench Grinder Wheel, Straight Grinder Wheel

Straight Grinder Wheels Trade Information

- Qingdao

- 1000 Set Per Month

- 30 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- Carton/pallet

- All India

- ISO

Product Description

Straight Grinding Wheels We are widely appreciated by clients for offering a wide collection of Straight Grinding Wheels. These wheels are manufactured using pristine quality raw materials and innovative techniques under the guidance of our adept professionals at our premises. The offered wheels are installed in grinding machines for metalworking and woodworking applications which gives proper finishing to the materials. In addition to this, the provided Straight Grinding Wheels can be bought from us in bulk at pocket friendly prices.

Straight Grinding Wheels Features:

- Easy to install

- Excellent durability

- Negligible maintenance

- Highly reliable

This straight grinding wheels produced with unique technique have the characteristics of uniform structure, correct hardness, geometrical precision and durable edge.

Straight grinding wheels are mainly used for grinding fine pitch crews, screws, studs, bolts, taps, pipe thread taps.

Straight Grinding Wheels Technical Date:

- Diameter: 350, 400, 450, 500mm

- Thickness: 8-32mm

- Hole: 160, 203, 229, 305.

- Bond: Vitrified

Note: Thickness is adjustable as customer's requirements.

Versatile and Durable Grinding Solutions

Our straight grinder wheels are designed to cover a wide range of grinding and surface preparation tasks. Whether you require a coarse finish for stock removal or a fine finish for precision work, these wheels cater to your requirement. Their vitrified and resin bonds, along with various grit sizes and hardness levels, ensure a perfect fit for industrial use.

Temperature-Resistant and Tough

Manufactured with high-quality aluminum oxide (Al2O3) and silicon carbide (SiC), these grinder wheels can withstand temperatures up to 1100C. This high temperature resistance makes them suitable for heavy-duty environments, ensuring long-lasting performance and reliability.

FAQs of Straight Grinder Wheels:

Q: How do I select the appropriate straight grinder wheel for my application?

A: Choosing the right straight grinder wheel depends on your specific task, material being worked on, and desired finish. Consider the grit size, bond type (vitrified or resin), hardness, and whether you need a wheel for coarse, medium, or fine finishing. Refer to the provided diameter, thickness, and bore size options to match your grinder.Q: What applications are these straight grinder wheels suitable for?

A: These wheels are ideal for grinding, surface preparation, and deburring. They can be used in manufacturing, metalworking, and fabrication settings, and are effective on a variety of metals and surfaces thanks to their robust construction and wide grit selection.Q: When should I replace my straight grinder wheel?

A: Replace the wheel when you notice a reduction in cutting efficiency, visible cracks, excessive wear, or if it no longer maintains its form. Always adhere to safety guidelines and inspect wheels before each use to ensure optimal operation.Q: Where are these grinding wheels manufactured and supplied from?

A: Our straight grinder wheels are manufactured in China and distributed globally. We cater to distributors, exporters, manufacturers, suppliers, and traders seeking quality industrial grinding solutions.Q: What is the recommended process for mounting and using these grinder wheels safely?

A: Ensure you match the wheels diameter, thickness, and bore with your grinders specifications. Install the wheel securely, follow manufacturer guidelines, and use proper personal protective equipment. Gradually increase operating speed up to the maximum of 3600 RPM and never exceed this limit.Q: What are the main benefits of using aluminum oxide and silicon carbide wheels?

A: Aluminum oxide wheels are known for their durability and ability to grind high-tensile materials, while silicon carbide wheels are suitable for harder or more brittle materials. Both types offer high toughness and temperature resistance, making them ideal for demanding industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese