Roll Grinding Wheels

5000-7000 USD ($)/Set

Product Details:

- Toughness High, engineered for heavy stock removal and long service life

- Grain Type Aluminium Oxide, Silicon Carbide, or Mixture

- Hardness Medium to Hard (specified as per application/material ground)

- Backing No backing (solid wheel) or Reinforced (fiber/cloth, on request)

- Shape Cylindrical, Straight-sided, or Custom Profiled

- Bonding Vitrified / Resin Bonded

- Chemical Composition Selected according to grain type, primarily Al2O3 or SiC in bonded matrix

- Click to View more

X

Roll Grinding Wheels Price And Quantity

- 0.15 - 7000.00 USD ($)/Set

- 1 Set

- 5000-7000 USD ($)/Set

Roll Grinding Wheels Product Specifications

- High, engineered for heavy stock removal and long service life

- Cylindrical, Straight-sided, or Custom Profiled

- Customized on demand

- 16 to 120 grit (customizable as per application)

- Aluminium Oxide, Silicon Carbide, or Mixture

- Roll Grinding Wheel

- Medium to Hard (specified as per application/material ground)

- Selected according to grain type, primarily Al2O3 or SiC in bonded matrix

- Abrasive grains bonded with vitrified or resin bonds

- Vitrified / Resin Bonded

- No backing (solid wheel) or Reinforced (fiber/cloth, on request)

- As per requirement (typically up to 700 mm diameter, length as per machine)

Roll Grinding Wheels Trade Information

- Qingdao

- 1000 Set Per Month

- 30 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- carton/pallet

- All India

- ISO 9000

Product Description

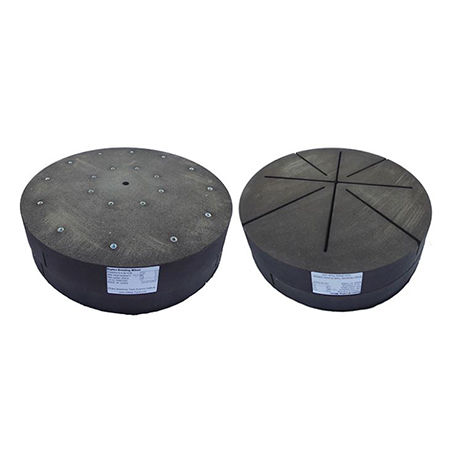

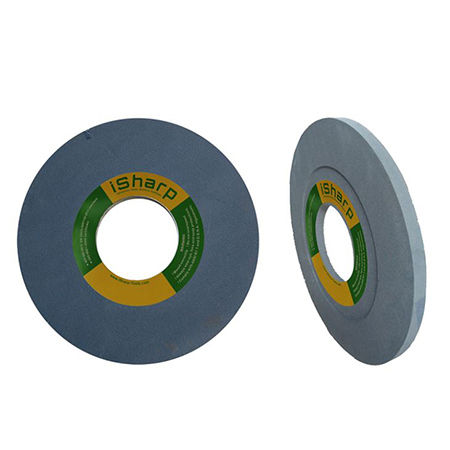

Roll Grinding Wheels

iSharp Abrasives Tools is a globally recognized manufacturer, supplier and exporter of premium range of Roll Grinding Wheels, which are manufactured with latest technology and high grade raw materials. These wheels are generally used in hot mill rolls, paper roll mills, etc. We welcome the inquiries of our customers for availing Roll Grinding Wheels at industry leading prices.

Roll Grinding Wheels Quick Information

- Brand Name: iSharp

- Place of Origin: China

- Diameter : 915mm

- Thickness : 100mm

- Hole : 305mm

Roll Grinding Wheels Applications:

- Hot-strip mill rolls that are referred as "chilled iron rolls". Generally, these rolls are available with nickel chill or nickel grain casting options and these are combined with molybdenum and nickel to transform these into alloy based metal.

- Cold strip mill rolls, most of which are forged steel. Very few of these metals are 86CrMOV7 or 4Cr5MOSiV1

- Steel made back-up rolls. Some of these metal rolls are made of cast iron

- Chilled iron made paper mill rolls. Some of these rolls have been fabricated by using steel and rubber.

Roll Grinding Wheels Packaging & Delivery

- Packing :cartons + Plywood Pallet

- Delivery Lead Time : 20-30 days after down payment

- Minimum Order : 1 Piece

- Supply Ability : 500 Piece/Pieces per Month

Outstanding Precision for Roll Grinding

Designed for cylindrical and precision roll grinding, these wheels enable consistent, fine surface finishes for steel, textile, paper, and printing rolls. Engineered to deliver accuracy and repeatability, they support applications demanding high tolerances and excellent surface integrity in industrial environments.

Customizable for Diverse Industrial Needs

Wheel diameters from 300 mm to 1060 mm, thicknesses up to 300 mm, and mounting holes customized to fit any grinding machine make these wheels adaptable. Available in straight-sided, cylindrical, or custom profiles, users benefit from the flexibility to meet specific grinding requirements.

Optimized Performance and Longevity

Constructed from high-toughness abrasive materials such as Aluminium Oxide or Silicon Carbide and bonded with vitrified or resin matrices, these wheels deliver heavy stock removal, long service life, and sustained hardness. Recommended for use in environments ranging from 10C to 50C, their robust design ensures reliable performance.

FAQs of Roll Grinding Wheels:

Q: How should I select the appropriate roll grinding wheel for my application?

A: Choose a roll grinding wheel by considering the roll material, required surface finish, machine speed rating, and desired wheel hardness. Specify the diameter, thickness, mounting hole size, grain type, and bonding material to match your grinding requirements.Q: What surfaces and finishes can be achieved with these grinding wheels?

A: Depending on the wheel specification and process, these wheels can achieve roughness levels up to Ra 0.2 micron, supporting precision grinding for steel, paper, textile, or printing rolls where a smooth finish is essential.Q: When is it recommended to use vitrified versus resin bonded wheels?

A: Vitrified bonded wheels excel in applications requiring high dimensional stability and cool cutting. Resin bonded wheels are preferred for high-impact tasks, greater resilience, or when grinding softer materials, depending on workflow needs.Q: Where can roll grinding wheels be used and what industries benefit most?

A: These wheels are widely utilized in steel mills, paper factories, textile plants, and printing facilities. Any industry requiring precise roll surface preparation, refurbishment, or finishing operations will benefit from using roll grinding wheels.Q: What is the recommended operating speed and temperature for these wheels?

A: Roll grinding wheels can operate safely at speeds up to 35 m/s, providing the machine rating permits. The suggested temperature range for operation is 10C to 50C to maintain optimal performance and wheel integrity.Q: How are roll grinding wheels packed and shipped?

A: For protection during transit and storage, wheels are packed in wooden boxes or cartons with additional protective materials. This ensures safe delivery to distributors, exporters, manufacturers, suppliers, and traders globally.Q: What are the advantages of using roll grinding wheels made with Aluminium Oxide or Silicon Carbide grains?

A: Aluminium Oxide offers durability and versatility for various metals, while Silicon Carbide delivers faster cutting and is ideal for harder surfaces or non-ferrous materials. The selection provides users with tailored performance and consistent results in demanding applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese