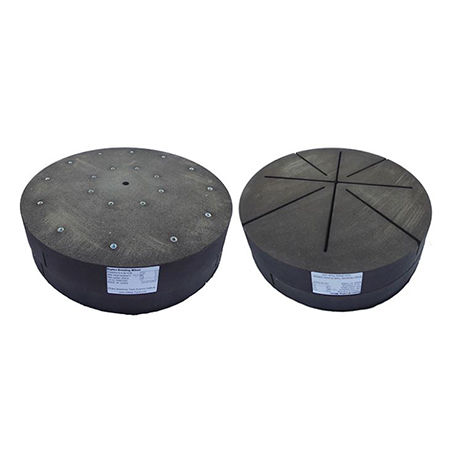

Straight Grinding Wheel

Product Details:

- Grain Type A (Aluminum Oxide) / C (Silicon Carbide)

- Shape Straight (Type 1)

- Bonding Vitrified or Resinoid Bond

- Toughness High

- Chemical Composition Abrasive grain, bonding agent, filler

- Hardness Soft, Medium, Hard (A to H)

- Material Aluminum Oxide or Silicon Carbide

- Click to View more

Straight Grinding Wheel Price And Quantity

- 5000-7000 USD ($)/Set

- 1 Set

- 0.15 - 7000.00 USD ($)/Set

Straight Grinding Wheel Product Specifications

- Straight (Type 1)

- 200 mm to 600 mm diameter

- Vitrified or Resinoid Bond

- High

- Aluminum Oxide or Silicon Carbide

- Soft, Medium, Hard (A to H)

- Abrasive grain, bonding agent, filler

- Straight Grinding Wheel

- A (Aluminum Oxide) / C (Silicon Carbide)

- 16 to 220 grit

Straight Grinding Wheel Trade Information

- 1000 Set Per Month

- 30 Days

Product Description

With a vision to serve clients in the best possible manner, we have been engaged in offering premium grade Straight Grinding Wheel, which is composed of an abrasive compound that is best for various grinding purposes. The provided wheel is also used in abrasive machining operations. This wheel is used for heavy-duty grinding because of its ability to withstand shock load. The provided wheel is highly admired among clients due to its vibration absorbing characteristic. It also finds its usefulness in grinding of cemented carbide and steel. Apart from this, offered Straight Grinding Wheel is available in different sizes as per clients demand.

Technical Specification

| Diameter (mm) | Hole(mm) | Thickness(mm) | |||||||||

| 25 | 32 | 40 | 50 | 63 | 75 | 100 | 125 | 150 | 200 | ||

| 250 | | | | | | | | | | | 32 |

| 300 | | | | | | | | | | | 75/127 |

| 350 | | | | | | | | | | | 75/127/203 |

| 400 | | | | | | | | | | | 127/160/203 |

| 450 | | | | | | | | | | | |

| 500 | | | | | | | | | | | 203/254/305 |

| 600 | | | | | | | | | | | |

| 750 | | | | | | | | | | | 305 |

Optimal Performance for Precision Grinding

Engineered for both surface and cylindrical grinding, this straight grinding wheel ensures high material removal rates and fine surface finish. Its robust structure allows for use on a range of metals and non-metals, delivering consistency across various industrial environments. Whether you need aggressive stock removal or delicate finishing, the wheels adaptable features guarantee reliable results every time.

Customizable Specifications for Versatile Needs

Available in multiple grain types, sizes, and hardness levels, the grinding wheel can be tailored to unique operational requirements. Choose between aluminum oxide or silicon carbide grains to match your material, and select the ideal thickness, diameter, and bonding type. The customizable hole diameter further enhances compatibility with different machines, optimizing performance and safety.

FAQs of Straight Grinding Wheel:

Q: How do I select the appropriate Straight Grinding Wheel for my application?

A: To choose the right grinding wheel, consider the material you are working on, desired finish, and machine compatibility. Aluminum oxide is ideal for steels, while silicon carbide suits non-ferrous metals and carbide tools. Additionally, select the right grain size, hardness, and bonding based on your grinding process and surface requirements.Q: What machines are compatible with this grinding wheel?

A: This straight grinding wheel is recommended for bench grinders and cylindrical grinders. The roll sizes range from 200 mm to 600 mm in diameter, and the hole diameter is customizable to fit various machine arbors, ensuring versatility across different setups.Q: When should I replace my grinding wheel?

A: Replace the grinding wheel if it shows signs of excessive wear, cracks, unevenness, or if the grinding efficiency decreases noticeably. Regular inspection is crucial for safety and maintaining optimal performance during surface or cylindrical grinding tasks.Q: Where can I use this type of grinding wheel?

A: These wheels are suitable for industrial settings such as workshops, manufacturing facilities, and metal fabrication plants. They are designed for surface grinding and cylindrical grinding of metals and non-metals, making them integral in metalworking and toolmaking environments.Q: What is the benefit of using vitrified or resinoid bond in grinding wheels?

A: Vitrified bonds offer rigid structure, excellent shape retention, and heat resistance, ideal for precise grinding. Resinoid bonds provide greater flexibility and impact resistance, making them suitable for high-speed applications. Choose the bond type based on your process requirements.Q: How does the grain size affect grinding performance?

A: Grain size determines the surface finish and material removal rate. Coarse grains (lower numbers) remove more material and are suitable for rough grinding, while finer grains (higher numbers) provide a smoother finish and are used for final surface preparation or fine grinding tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese