vitrified grinding wheel

Product Details:

- Backing No backing; homogeneously bonded

- Grain Type A (Aluminum Oxide), C (Silicon Carbide)

- Bonding Vitrified Bond

- Hardness Soft to hard grades available

- Chemical Composition Al2O3, SiC, vitrified bonding agents

- Toughness High fracture resistance

- Shape Flat, Dish, Cup, Cylinder

- Click to View more

vitrified grinding wheel Price And Quantity

- 10 Piece

- 2 USD ($)/Piece

vitrified grinding wheel Product Specifications

- Flat, Dish, Cup, Cylinder

- A (Aluminum Oxide), C (Silicon Carbide)

- Vitrified Bond

- High fracture resistance

- Vitrified Grinding Wheel

- Varies from 100mm to 500mm diameter

- Aluminum Oxide / Silicon Carbide

- Al2O3, SiC, vitrified bonding agents

- No backing; homogeneously bonded

- Soft to hard grades available

- 24 to 600 mesh

- Width: 10mm to 100mm

Product Description

Specifications of White Aluminum Oxide Bench Grinding Wheel:

| type 1 | Diameter (mm) | Hole(mm) | Thickness(mm) |

| 250 | 32 | 25/35 | |

| 300 | 75/76.2/127 | 32/40/50 | |

| 350 | 75/76.2/127/203 | 32/40/50 | |

| 400 | 127/160/203 | 32/40/50/63 | |

| 450 | 203/254/305 | 32/40/50/63/75 | |

| 500 | 305 | 32/40/50/63/75/100 | |

| 600 | 305 | 32/40/50/63/75/100/125 | |

| 650 | 305 | 33/40 | |

| 750 | 305 | 22/25/28/33/40/43/58/61/67/86 | |

| 900 | 305 | 22/25/28/32/33/38/40/42/43/47/52/55/58/61/72/75/78/82/90 | |

| 1065 | 304.8 | 22/25/32/38/42/47/52/55 | |

| 1100 | 305 | 25/32/33/38/40/43/55/58/61/72/75/82/86/90 | |

| 1200 | 305 | 120/150 | |

| 1250 | 305 | 42/75/80 | |

| 1400 | 305 | 80/86/120 | |

| 1600 | 305 | 80/86/120 | |

| 1600 | 900 | 86/90/120 | |

| 1800 | 305 | 90/120 |

1. Aluminum oxide is the most popular abrasive and is generally recommended for grinding most steels, annealed iron, malleable and ductile iron, and non-ferrous cast alloys.

2. White aluminum oxide is a highly refined aluminum oxide, this white abrasive has exceptionally fast and cool cutting and grinding properties, especially suitable for grinding operations on hardened steel or high-speed steel in various precision grinding.

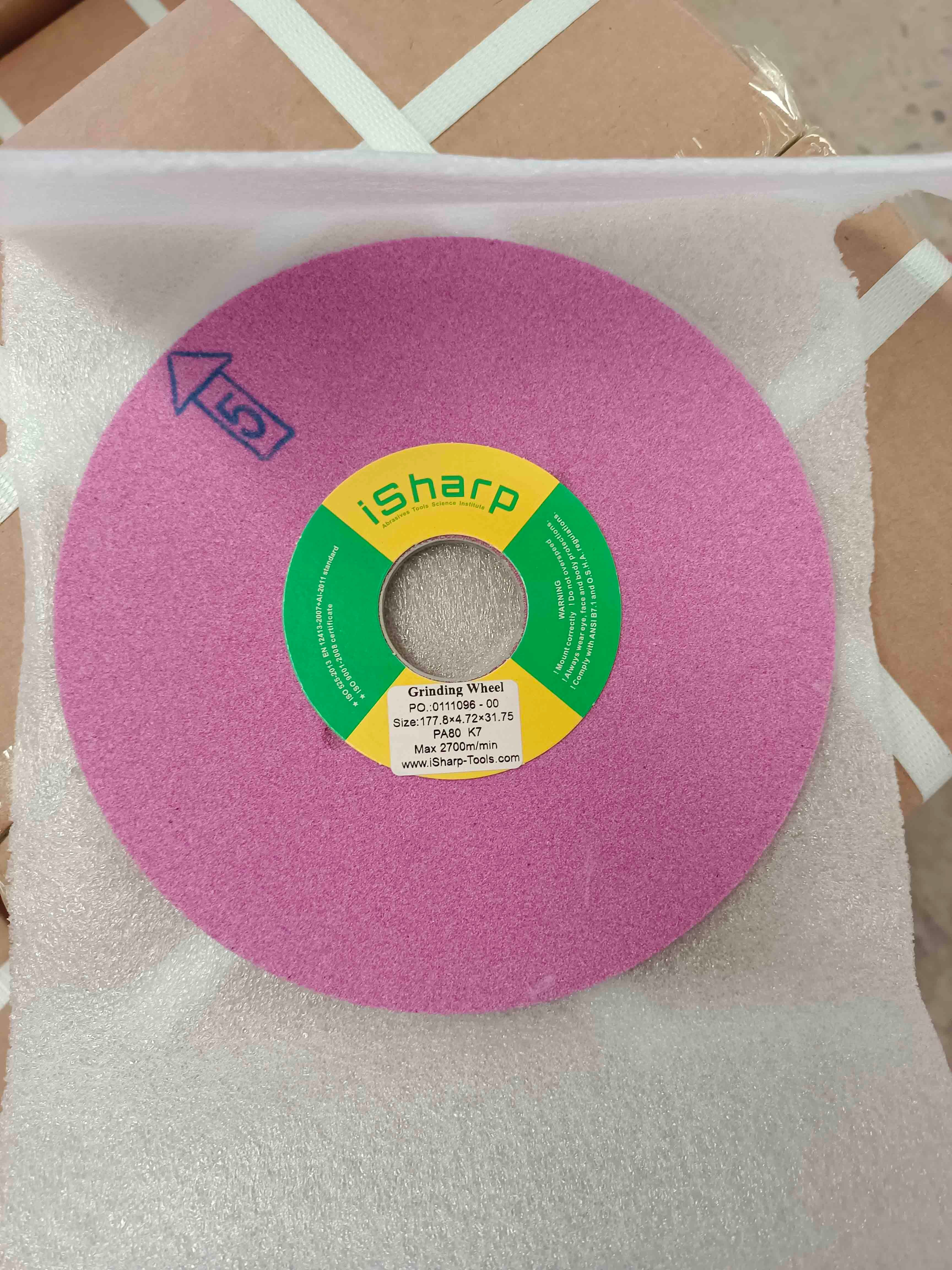

3. Pink aluminum oxide is slightly harder and less brittle than white abrasives, while still maintaining its machinability characteristic. This is especially suitable for grinding wear-resistant, heat-sensitive tool steels.

FAQ

1. who are we?

We are based in Henan, China, start from 2013,sell to Domestic Market(20.00%),Western Europe(13.00%),Mid East(10.00%),Eastern Europe(10.00%),North America(9.00%),South Asia(7.00%),Southeast Asia(6.00%),Southern Europe(5.00%),Central America(5.00%),Oceania(5.00%),Africa(5.00%),South America(3.00%),Eastern Asia(2.00%). There are total about 301-500 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Honing stone, Grinding wheel, grinding wheel making machine,flap disc machine,coated abrasive machinery, abrasive tools, cutting discs

4. why should you buy from us not from other suppliers?

Experienced abrasives engineers constitute a research team from 1991. Adhering to the "Green, Efficiency, Precision" concept, we design, develop and produce suitable abrasive products, provide a complete grinding technology services.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,CPT,Express Delivery;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,Western Union,Cash;

Language Spoken:English,Chinese

Versatile Material Options

Choose between aluminum oxide for robust general-purpose grinding or silicon carbide for specialized applications requiring sharper cutting actions. Our vitrified bond ensures grain retention and consistent performance, while customizable porosity addresses unique cooling and chip evacuation needs.

Precision Engineering for Superior Finish

With smooth finishing and a broad range of grain sizes (24 to 600 mesh), our grinding wheels cater to both rough and fine grinding requirements. Their homogeneously bonded composition guarantees high fracture resistance and dimensional accuracy during prolonged use.

Flexible Sizing and Shape Choices

Available from 100mm to 500mm in diameter, in flat, dish, cup, and cylinder shapes, our wheels adapt seamlessly to industry-standard machines. The central bore is tailored per machine specification for secure and precise mounting.

FAQ's of vitrified grinding wheel:

Q: How should vitrified grinding wheels be selected for specific applications?

A: Selection should be based on your grinding needs-choose aluminum oxide for general-purpose surfaces and tool sharpening, or silicon carbide for harder materials. Take into account wheel shape, grain size, porosity, and hardness to match the specific requirements of your machinery and application.Q: What is the typical process for mounting these grinding wheels?

A: The wheels feature a central bore tailored to your machine's specification. Ensure the wheel is correctly aligned and securely fixed using suitable flanges. Always perform a safety check and conduct a trial run before full-scale operation.Q: When should a grinding wheel be replaced?

A: Replace your vitrified grinding wheel when there are visible signs of wear, cracks, excessive loading, or if its diameter has reduced below the manufacturer's recommended limit. Regular inspection ensures quality results and operational safety.Q: Where can these vitrified grinding wheels be used?

A: They are suitable for industries involved in metalworking, automotive, tool manufacturing, and maintenance workshops. The wide application includes surface grinding, cylindrical grinding, and sharpening operations on various metallic and hard materials.Q: What are the main benefits of using vitrified bonded grinding wheels?

A: Vitrified wheels offer excellent durability, resistance to wear and corrosion, and high fracture resistance. Their customizable porosity enhances coolant flow, reducing thermal damage and ensuring a superior surface finish, even at speeds up to 35 m/s.Q: How does grain size and hardness affect grinding performance?

A: Coarser grain sizes (lower mesh numbers) excel at rapid material removal, while finer grains (higher mesh numbers) produce smoother finishes. Selecting the appropriate hardness further tailors the wheel to either softer or harder workpieces, optimizing efficiency and finish.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese