30 आईएनआर/टुकड़ा

उत्पाद विवरण:

- कठोरता Medium to Hard

- बेरहमी High Toughness

- शेप Rectangular / Block

- अनाज का प्रकार Monocrystalline

- बॉन्डिंग Vitrified

- रासायनिक संरचना Al2O3 > 98%

- मटेरियल Aluminium Oxide

- अधिक देखने के लिए क्लिक करें

X

मूल्य और मात्रा

- 3000

उत्पाद की विशेषताएं

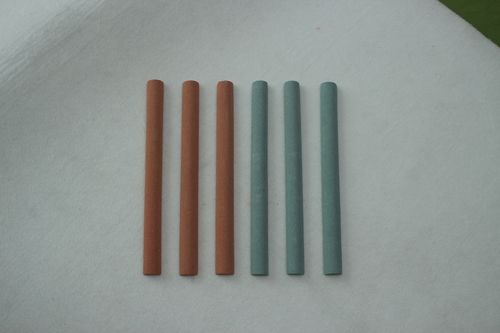

- Dressing Stone

- Medium to Hard

- 100 x 15 x 10 mm

- High Toughness

- Aluminium Oxide

- 15 x 10 x 100 mm

- Monocrystalline

- Vitrified

- Al2O3 > 98%

- 80, 120, 180, 220 Grit

- Rectangular / Block

उत्पाद वर्णन

Our products has exported to many countries such as Russia America Germany Italy Ukraine Singapore Brazil Mexico Poland And so on Besides we also have built business relationship with some famous company in this field such as Klingspor Deerfos Sunmight CGW and so on Having been innovating the cutting disc and grinding wheel industry for over 15 years you can count on our products to perform consistentAny questions please contact us

Nancy Lu iSharp Abrasives Tools Science Institute

Add A2507 Kaixuanmen Tongbai S RdZhengzhou Henan 450006 China

FAQ

Q1 Are you a manufacturer or a trading company

We are a professional manufacturer of abrasive tools with the whollyowned trading company as well You are warmly welcome to have an onthespot investigation to our factory

Yes OEM services are available and we have rich experience in OEM

Yes free samples is available for quality checking before orders

Yes we have

The quality of the product is the fundamental to serve our customers well One the one hand we insist on innovation introduction outstanding talents equipment and technology to fully achieve the quality of products to meet customers needs requirements on the other hand we adopt advanced management method especially the quality test management

TT 30 as deposit and 70 before delivery and different quantities decide different payment terms Well show you the photos of the products and packages before you pay the balance payment

Generally it will take 15 to 40 working days after receiving your advance payment But the specific delivery time depends on the items and the quantity of your order

Precision Dressing for Diamond Wheels

Our dressing stone is crafted to rejuvenate and clean diamond grinding wheels used in the demanding glass industry. Its monocrystalline aluminium oxide composition ensures consistent dressing performance while maintaining the wheel's integrity, making it an indispensable maintenance tool for manufacturers, suppliers, and traders worldwide.

Universal Compatibility and Durability

Engineered for universal compatibility, this dressing stone works seamlessly with all types of diamond grinding wheels. Its robust vitrified bonding and high toughness mean it can endure heavy use at high temperatures, providing longevity and reliability for continuous industrial applications.

Versatile Sizing and Easy Handling

Available in standard roll and strip sizes within individual box packaging, our dressing stone offers flexibility in use and secure storage. With options ranging from 80 to 220 grit sizes, users can choose the best grit for their specific dressing needs, ensuring optimal grinding wheel condition for every application.

FAQ's of Dressing Stone for Diamond Grinding Wheel Glass Industry:

Q: How do I use the dressing stone for diamond grinding wheels in the glass industry?

A: To use the dressing stone, run your diamond grinding wheel at operational speed and gently press the dressing stone against the rotating wheel. Move the stone across the wheel's surface evenly to remove debris, re-expose abrasive grains, and maintain the wheel's cutting efficiency.Q: What are the main benefits of using this dressing stone on diamond grinding wheels?

A: Using this dressing stone regularly optimizes grinding wheel performance by cleaning off glazing and embedded particles. It restores the wheel's cutting ability, extends its service life, and ensures consistent, high-quality processing of glass materials.Q: When should I dress my diamond grinding wheel using the dressing stone?

A: Dress your diamond grinding wheel whenever you notice decreased cutting efficiency, uneven wear, or surface glazing. Regular dressing prevents clogging and damage, which improves overall productivity and finish quality in glass processing operations.Q: Where is this dressing stone manufactured and supplied from?

A: This dressing stone is produced, exported, and supplied by experienced manufacturers and distributors in China, ensuring quality control and reliable delivery to global trade partners in the glass industry.Q: What grit size should I choose for my application?

A: The choice of grit depends on the level of dressing required. Coarser grits such as 80 are ideal for heavy dressing, while finer grits like 220 are suitable for precise, finishing work. Selecting the appropriate grit helps maintain your grinding wheel's optimal condition.Q: How should I store the dressing stone to maintain its quality?

A: Store the dressing stone in a cool, dry place, ideally in its original individual box packing. Proper storage ensures an indefinite shelf life by preventing moisture absorption and contamination, preserving the stone's durability and effectiveness.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese