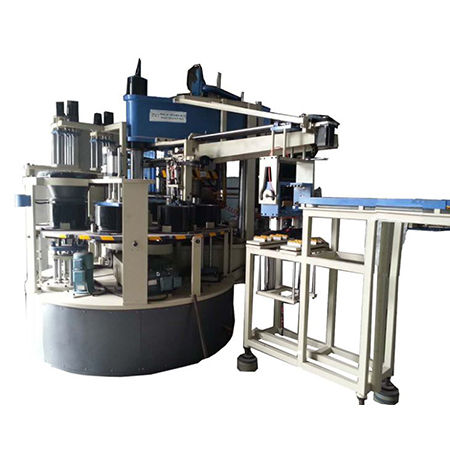

300-400 मिमी कटिंग एंड ग्राइंडिंग व्हील मेकिंग मशीन

5000-7000 USD ($)/Set

उत्पाद विवरण:

- रासायनिक संरचना Steel frame with precision cast iron parts and industrial composite panels

- अनाज का प्रकार Aluminum oxide, silicon carbide

- बैकिंग Reinforced fiberglass or mesh backing

- बॉन्डिंग Resinoid & vitrified bonding options

- कठोरता Adjustable via machine controls

- बेरहमी Engineered for industrial-grade durability and longevity

- शेप Round / Disc

- अधिक देखने के लिए क्लिक करें

X

300-400 मिमी कटिंग एंड ग्राइंडिंग व्हील मेकिंग मशीन मूल्य और मात्रा

- 1

- सेट/सेट्स

- सेट/सेट्स

- Emergency stop, overload protection, interlocked guards

- Precision heating system up to 120°C

- 4200mm x 2100mm x 1700mm

- Fully automatic with manual setting options

- Approx. 3500kg

- 5kW Heavy Duty Industrial Motor

- 220V/380V three-phase, 50/60Hz

- Manufacture of cutting and grinding wheels for industrial and commercial use

- Low maintenance with easy-access service panels

- 300mm, 350mm, 400mm

- Up to 10mm

- Adjustable up to 120T

- 600-1200 wheels per hour

- PLC based touch panel interface

300-400 मिमी कटिंग एंड ग्राइंडिंग व्हील मेकिंग मशीन उत्पाद की विशेषताएं

- Round / Disc

- Assorted abrasive grains from 24 to 120 grit

- Engineered for industrial-grade durability and longevity

- Adjustable via machine controls

- Resinoid & vitrified bonding options

- Automatic Cutting & Grinding Wheel Forming Machine

- Reinforced fiberglass or mesh backing

- 300-400mm

- Variable, compatible with 300-400mm wheel formats

- Steel Structure with alloy components

- Aluminum oxide, silicon carbide

- Steel frame with precision cast iron parts and industrial composite panels

- Emergency stop, overload protection, interlocked guards

- Precision heating system up to 120°C

- 4200mm x 2100mm x 1700mm

- Fully automatic with manual setting options

- Approx. 3500kg

- 5kW Heavy Duty Industrial Motor

- 220V/380V three-phase, 50/60Hz

- Manufacture of cutting and grinding wheels for industrial and commercial use

- Low maintenance with easy-access service panels

- 300mm, 350mm, 400mm

- Up to 10mm

- Adjustable up to 120T

- 600-1200 wheels per hour

- PLC based touch panel interface

300-400 मिमी कटिंग एंड ग्राइंडिंग व्हील मेकिंग मशीन व्यापार सूचना

- 1000 प्रति महीने

- 30 दिन

- Yes

- नमूना लागत, शिपिंग और करों का भुगतान खरीदार द्वारा किया जाना है

- ऑल इंडिया

उत्पाद वर्णन

Technical Specification

| Product name | cutting and grinding wheel making machine |

| Cutting disc diameter | 300 350, 400mm |

| Cutting disc thickness | 2.5-4.0mm |

| Cutting disc hole size | 25.4/32 mm |

| Structure | Multi-position pusher type, single mode cavity |

| Main cylinder nominal pressure | 300T/400T/500T |

| Control mode | Digital display, PLC control |

| Mould rotating speed | 20-50 R/Min |

| Each leveling micro-lift | Servo motor 0.05-3.0mm |

| Working beat | 12-14 second per grinding wheel |

| Capacity | 2100-2400 pcs / 8 hours |

| Operators | 2-3 persons |

| Installed power | 31KW (including heating power) |

| Consumption power | 9-12KW |

| Total weight | 13000kg |

| Delivery time | 75-90 days after received deposit |

| Packing | Naked or pallet |

| Service | Engineers available to service machinery overseas |

Efficient and Versatile Production

This machine efficiently produces a wide range of cutting and grinding wheels with diameters of 300mm, 350mm, and 400mm. Featuring fully automatic operation, it boosts productivity for manufacturers and suppliers while maintaining consistent wheel quality thanks to its adjustable pressure, temperature control, and variable grit handling.

Advanced Control and Safety

Equipped with a user-friendly PLC-based touch panel, operators access intuitive controls for setting thickness, hardness, and process variables. Integrated emergency stops, overload protection, and interlocked guards reinforce safety, ensuring smooth operation and rapid response during unexpected events.

Durable Construction, Easy Maintenance

Engineered with a steel structure, precision cast iron parts, and industrial composite panels, the machine offers exceptional durability and industrial-grade longevity. Its low-maintenance design includes easy-access service panels, making scheduled upkeep quick and straightforward for operators and technicians.

FAQs of 300-400mm Cutting and Grinding Wheel Making Machine:

Q: How does the machine control wheel thickness and hardness?

A: Wheel thickness (up to 10mm) and hardness are managed via the PLC touch panel, allowing operators to precisely adjust compression pressure (up to 120T) and temperature (up to 120C) depending on the desired end product specifications.Q: What types and sizes of wheels can this machine manufacture?

A: The machine manufactures cutting and grinding wheels in round/disc shapes, compatible with 300mm, 350mm, and 400mm diameters, and supports assorted abrasive grains from 24 to 120 grit, using resinoid or vitrified bonding. Reinforced fiberglass or mesh backing options are also supported.Q: Where can the machine be installed and what are the power requirements?

A: Ideal for industrial production facilities, the machine requires a three-phase power supply220V or 380V at 50/60Hz. Its robust steel design supports use in demanding environments typical of manufacturing, distribution, or export operations.Q: What safety features does the machine include?

A: Safety is assured with features such as a prominent emergency stop button, overload protection systems, and interlocked guards, all of which prevent accidental operation and safeguard the operator throughout the production cycle.Q: What is the process for manufacturing wheels with this machine?

A: Operators load abrasive materials and bonding agents, select wheel size, grain, and thickness on the control panel, then initiate fully automatic production. The machine controls temperature, pressure, and curing time, ensuring precision and consistency in every wheel produced.Q: What are the main benefits of using this machine for wheel production?

A: Benefits include high-speed, consistent output (600-1200 wheels per hour), flexible settings for various specifications, industrial-grade durability, low maintenance, and comprehensive safety systems. These advantages help manufacturers meet large order requirements efficiently and reliably.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese