Dressing Oil Stone

Product Details:

- Bonding Vitrified Bond

- Shape Rectangular Block

- Chemical Composition Mainly Silicon Carbide (SiC) or Aluminium Oxide (Al2O3)

- Hardness Medium to Hard

- Grain Type Single or Mixed (Silicon Carbide or Aluminium Oxide)

- Toughness High

- Material Abrasive Stone (Silicon Carbide/Aluminium Oxide)

- Click to View more

Dressing Oil Stone Price And Quantity

- 1 Set

- 5000-7000 USD ($)/Set

- 0.15 - 7000.00 USD ($)/Set

Dressing Oil Stone Product Specifications

- 150 mm x 50 mm x 25 mm (standard); Other sizes available

- Abrasive Stone (Silicon Carbide/Aluminium Oxide)

- Mainly Silicon Carbide (SiC) or Aluminium Oxide (Al2O3)

- Medium to Hard

- Rectangular Block

- High

- Single or Mixed (Silicon Carbide or Aluminium Oxide)

- Vitrified Bond

- Available in Fine, Medium, Coarse

- Dressing Oil Stone

Dressing Oil Stone Trade Information

- 1000 Set Per Month

- 30 Days

Product Description

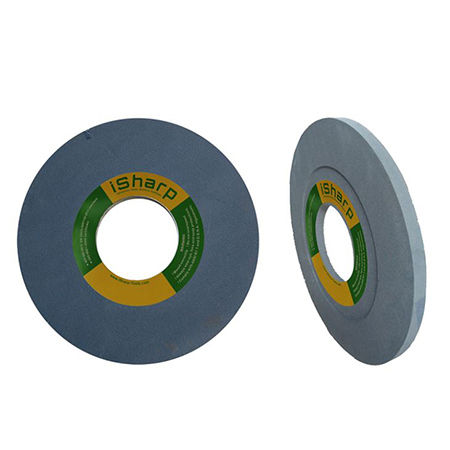

We are considered as one of the renowned companies in manufacturing and exporting premium quality Dressing Oil Stone, that is best suitable to be used for making grinding wheels which find their usefulness for sharpening operation of industrial applications. Offered stone has numerous properties such as high strength, longer life, waterproof in nature and free from defect. Provided stone is prepared with the latest innovative techniques under the supervision of our dexterous professionals at the ultra-modern production unit. Apart from this, provided Dressing Oil Stone is safely packed to prevent damage during transit.

Technical Specification

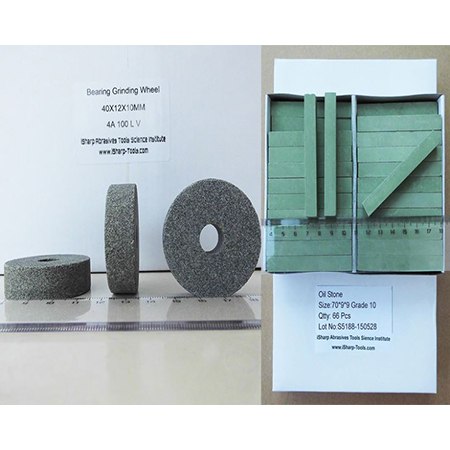

| Type | Length(mm) | Widthmm) | Thickness(mm) | Grit |

| Rectangular | 30 | 13 | 9 | W7/W10/W20 |

| 35 | 9/12/14/16 | 9 | ||

| 40 | /1416/18 | 9 | ||

| 70 | 9/10/11/12/12.6/13/ | 9 | ||

| Round Files | Diameter(mm) | Thickness(mm) | Holes(mm) | Grit |

| 14.5/16/20/29/30/31/32/34/38/39/48/50/50 | 12/14.5/16/18/19//20 | 6/10/12/14/16 | 100 |

Engineered for Precision Durability

The Dressing Oil Stone combines advanced vitrified bonding and high-quality grains to deliver a reliable tool for surface finishing and sharpening. Its robust structure is resistant to high temperatures and designed to maintain its shape and efficacy over repeated use, making it a reusable and lasting addition to any workshop or industrial setting.

Versatile Application and Compatibility

Suitable for a variety of tasks, this dressing oil stone can be used with both oil and water lubricants, offering smooth operation and adaptability to different preferences or tool requirements. Available in standard and customized sizes, the rectangular block format meets diverse sharpening and dressing needs.

FAQs of Dressing Oil Stone:

Q: How do I use the dressing oil stone for sharpening tools and blades?

A: To use the dressing oil stone, apply a thin layer of oil or water on the surface of the stone. Hold the tool at the desired angle and move it evenly across the stone in a consistent motion. Repeat this process until the desired sharpness or finish is achieved. Remember to clean the stone after use to maintain its effectiveness.Q: What types of abrasive materials are used in this dressing oil stone?

A: This stone is primarily composed of either silicon carbide (SiC) or aluminium oxide (Al2O3), both renowned for their toughness and durability. These materials ensure high performance when dressing, sharpening, or finishing a variety of tools and blades.Q: When should I choose fine, medium, or coarse grain sizes?

A: Select coarse grains for quick material removal, medium grains for regular sharpening, and fine grains for finishing or achieving a smooth edge. Your choice depends on the initial condition of the tool and the desired result.Q: Where can these dressing oil stones be used?

A: These stones are suitable for industrial, workshop, and general-purpose applications, making them ideal for use by manufacturers, distributors, exporters, suppliers, and traders, particularly within China and worldwide.Q: What are the benefits of using an oil-filled dressing stone?

A: The oil-filled feature ensures smoother sharpening by reducing friction and preventing clogging with debris. This results in a more uniform finish and extends the longevity of both the stone and the tools being maintained.Q: Can I use water instead of oil as a lubricant?

A: Yes, the dressing oil stone is compatible with both oil and water lubricants. You can choose either based on your working environment and personal preference, without affecting performance.Q: What is the standard size and weight of each dressing oil stone?

A: A standard dressing oil stone measures 150 mm x 50 mm x 25 mm and typically weighs between 400 and 600 grams. Custom sizes are also available upon request to suit various applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese