Crankshaft Grinding Wheel

Product Details:

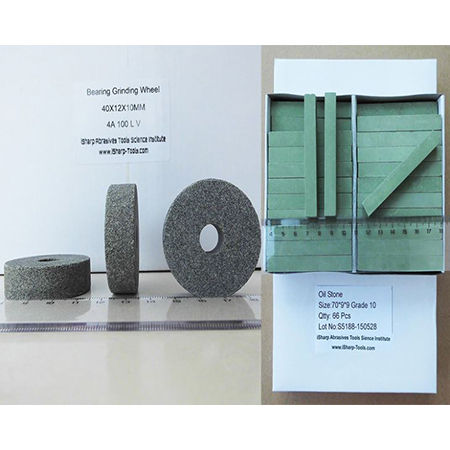

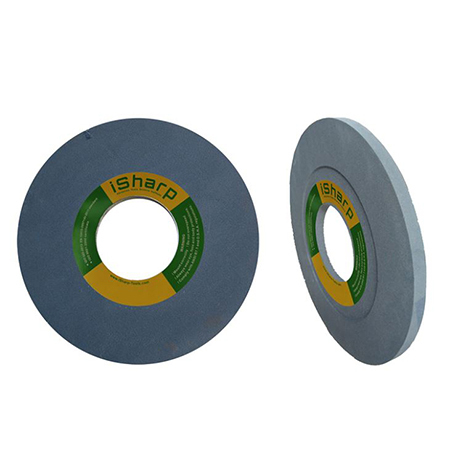

- Shape Round

- Chemical Composition Al2O3, Bonding agents

- Bonding Vitrified

- Grain Type Coarse and Fine

- Toughness High

- Hardness Medium to Hard

- Material Aluminium Oxide

- Click to View more

Crankshaft Grinding Wheel Price And Quantity

- 0.15 - 7000.00 USD ($)/Set

- 5000-7000 USD ($)/Set

- 1 Set

Crankshaft Grinding Wheel Product Specifications

- Aluminium Oxide

- Medium to Hard

- 355 mm x 50 mm x 127 mm

- Customisable

- High

- Crankshaft Grinding Wheel

- Coarse and Fine

- 46 to 80 Grit

- Vitrified

- Al2O3, Bonding agents

- Round

Crankshaft Grinding Wheel Trade Information

- 1000 Set Per Month

- 30 Days

Product Description

Being a reputed name in this domain, we have been engaged in manufacturing and supplying supreme grade Crankshaft Grinding Wheel that finds its usefulness in the automobile and manufacturing industries. The provided wheel is well suited to be used to grinding various crankshafts of tractors, vessels, and other machines. It is perfect for cylindrical grinding. This wheel is safely packed to prevent damage during transit. The offered wheel is checked on various parameters for ensuring defect-free delivery to clients. In addition to this, the provided Crankshaft Grinding Wheel is appreciated among clients owing to its robustness and enhanced durability.

Technical Specification

| D | T | H | |||||||||||||||||||||||

| 22 | 25 | 28 | 32 | 33 | 38 | 40 | 42 | 43 | 47 | 52 | 55 | 58 | 61 | 67 | 72 | 75 | 78 | 80 | 82 | 86 | 90 | 120 | 150 | ||

| 650 | | | | | | | | | | | | | | | | | | | | | | | | | 305 |

| 750 | | | | | | | | | | | | | | | | | | | | | | | | | |

| 900 | | | | | | | | | | | | | | | | | | | | | | | | | |

| 1065 | | | | | | | | | | | | | | | | | | | | | | | | | 305 |

| 1100 | | | | | | | | | | | | | | | | | | | | | | | | | 305 |

| 1200 | | | | | | | | | | | | | | | | | | | | | | | | | |

| 1250 | | | | | | | | | | | | | | | | | | | | | | | | | |

| 1400 | | | | | | | | | | | | | | | | | | | | | | | | | |

| 1600 | | | | | | | | | | | | | | | | | | | | | | | | | |

Precision and Versatility for Crankshaft Grinding

Our 600 mm diameter crankshaft grinding wheel offers customizable dimensions to fit diverse engine workshop requirements. With options for different wheel thickness, centre hole diameter, and grit types, each wheel is optimized for robust durability and precise material removal. Ideal for heavy-duty and high-volume applications, the wheel ensures optimal surface finish and efficiency, whether you require coarse stock removal or fine polishing.

Engineered for Superior Performance and Durability

Constructed from high-quality Aluminium Oxide or Silicon Carbide with a tough vitrified bond, this grinding wheel withstands demanding industrial settings. Its design allows for consistent performance at speeds up to 35 m/s, depending on application needs. Available in a range of hardness grades and grit sizes, the wheel suits both wet and dry grinding processes, combining safety with reliable, long-lasting efficiency.

FAQs of Crankshaft Grinding Wheel:

Q: How is the 600 mm Crankshaft Grinding Wheel used in the automotive industry?

A: The wheel is primarily used for grinding crankshafts in the automotive and engine industry, ensuring smooth and precise surfaces essential for engine performance. It supports both wet and dry grinding processes depending on the workshops setup.Q: What customization options are available for this crankshaft grinding wheel?

A: Besides the standard 600 mm diameter and 50 mm thickness, the wheel can be customized for different diameters, thicknesses, centre hole dimensions, strip sizes, grain sizes, grades, and grit types to match specific application requirements.Q: When should I select a different grit type or hardness for the grinding wheel?

A: Choose a coarser grit (like 46) and harder grade for high stock removal or tougher materials, and a finer grit for a smoother, precision finish. Match the wheels hardness and abrasiveness to the crankshaft material and desired surface quality.Q: Where is this grinding wheel typically applied and by whom?

A: It is used globally, particularly by automotive workshops, engine rebuilders, and manufacturers specializing in crankshaft repair or production. The product is distributed, exported, and supplied by trusted manufacturers and traders, especially from China.Q: What is the recommended process for safely operating the crankshaft grinding wheel?

A: Always operate within the specified maximum speed of 35 m/s, ensure secure mounting on compatible equipment, select the correct grit and grade, and use suitable safety gear. The wheel can be employed in both wet and dry grinding setups to optimize results.Q: What benefits does this wheel offer over standard grinding solutions?

A: This grinding wheel delivers high stock removal efficiency, minimal heat buildup, and a consistently fine or precise finish. Its robust chemical composition and construction provide long service life and adaptability for various grinding needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+